Surface film resistance reduction method and viscoplastic material pipe-line transportation technology

A viscoplastic material and pipeline transportation technology, which is applied in the field of pipeline transportation of viscoplastic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

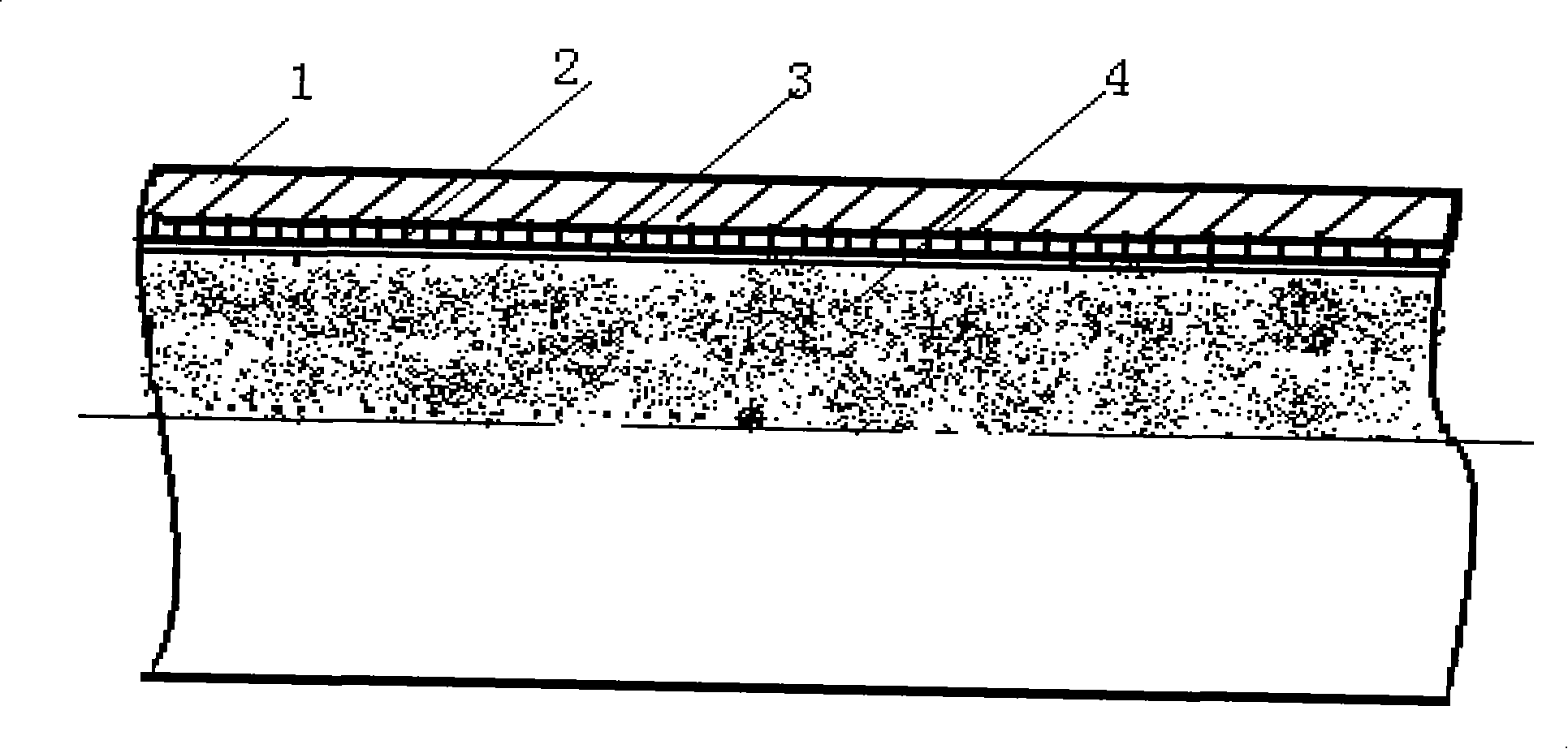

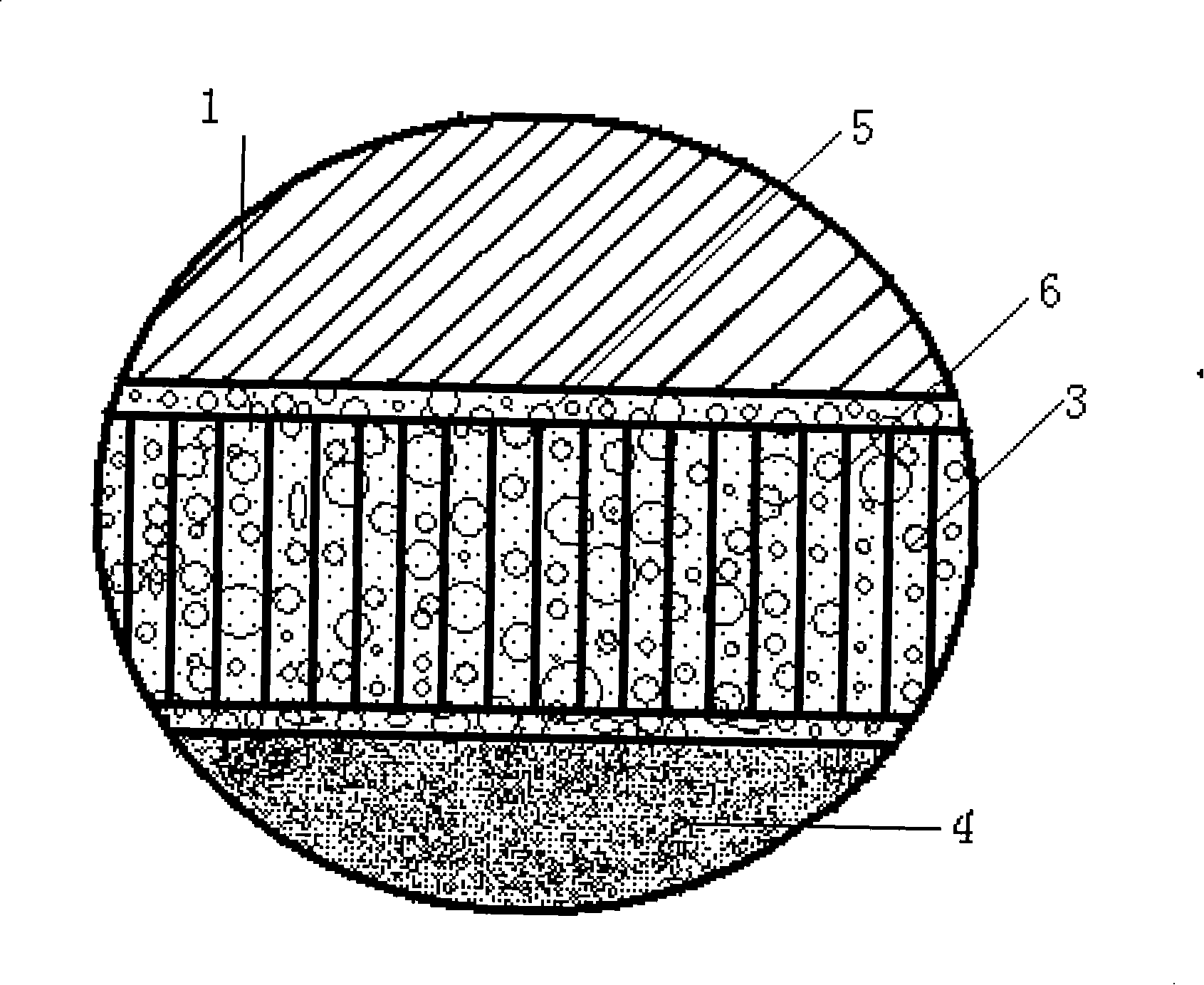

[0032] Embodiment 1 Hydraulic type soft clay coating conveying method. Soft clay refers to the saturated soil that is deposited in still water or slow flowing water environment, formed by biochemical action, contains organic matter, has a natural water content greater than the liquid limit, and a natural void ratio greater than 1.0. Soft clay is neither liquid nor solid, and belongs to the category of Binghamian body, and has the characteristics of weakness, viscosity, thixotropy, rheology, permeability, and compressibility. The non-Newtonian fluid characteristics of this soft and viscous material and its reconsolidation characteristics under disturbance have great viscous resistance. With regard to the prior art and equipment of transporting earth, if the mud concentration is greater than 30%, it cannot be transported; if the powdery dry soil is slightly wet, it cannot be transported. However, the natural state of a large amount of soil in the project is in the range that is...

Embodiment 2

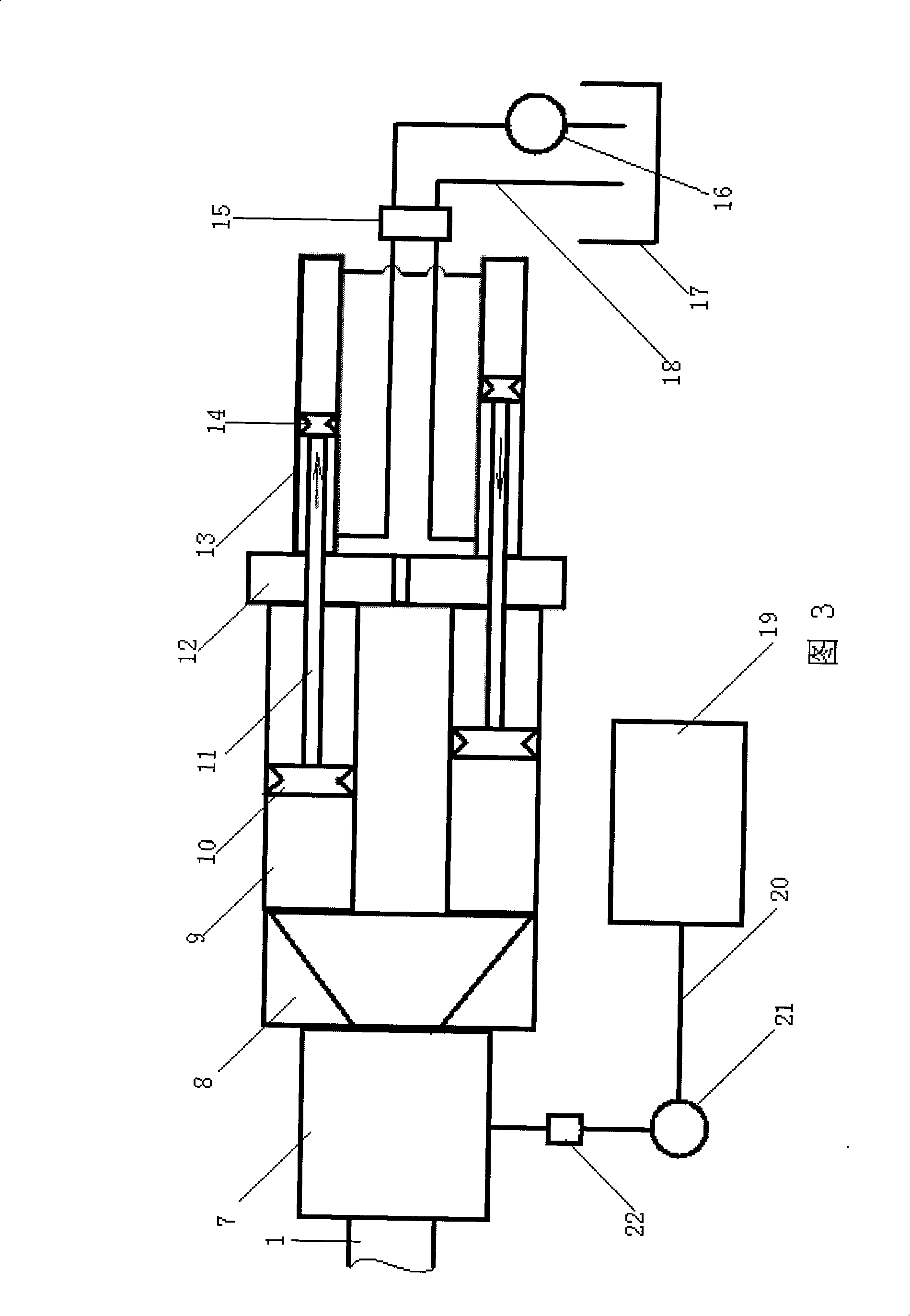

[0037] Embodiment 2 Double-pipeline dredger. Including pusher, material inlet, material delivery pipeline, conversion valve, surface film generator, material distribution device, intelligent control system, etc., such as Figure 5 Figure 6 Shown, be provided with crane (39), grab bucket (40) and hopper (42) on hull. Crane (39) grabs earth (41) and puts into hopper (42) along the side of the ship, and earth (41) is pressed into main conveying pipeline (46) by hydraulic propulsion device. Main conveying pipeline (46) adorns a booster (45) every certain distance. Main delivery pipeline (46), cable and auxiliary pipeline (48) are laid in parallel, are fixed on the reinforcing bar (51) of buoyant body (44) with hugging (52) screw (49). Whether booster (45) communicates with auxiliary pipeline (48) is controlled by electromagnetic valve (50). When the resistance of the soil (41) traveling in the main conveying pipeline (46) is large, the solenoid valve (50) is opened, and the h...

Embodiment 3

[0039] Embodiment 3 Concrete delivery. When transporting concrete, only the membrane device is added on the basis of the original concrete delivery pump. The surface film liquid adopts defoaming agent and its ratio is: calcium lignosulfonate 0.3% ~ 1.2%, polyoxyethylene ether 0.01% ~ 0.05%, cyclohexanol 0.01% ~ 0.05%, water is added to 1%. Hundred.

[0040] When the surface film liquid is sprayed on the concrete and the inner wall of the pipe, the cement particles are negatively charged due to the adsorption of anions, which makes the water around the cement particles polarized, and the repulsion of the same-sex ions prevents the adsorption and diffusion of the cement particles and inhibits the concrete. Therefore, the slurry becomes thinner, the viscous resistance between the concrete and the inner wall of the pipe decreases, and the fluidity of the concrete increases. Through comparative experiments, the frictional resistance between the concrete and the road wall is signif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com