Insulating film

A technology of insulating films and devices, applied in the direction of organic insulators, plastic/resin/wax insulators, electrical components, etc., can solve problems such as cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] In the production method of the composition of the present invention, the polymerization of compound (I) is preferably followed by treatment such as removal of high molecular components by filtration or centrifugation or purification by column chromatography.

[0086] Specifically, it is preferable that, as a preparation method of the composition of the present invention, the solid formed by the polymerization reaction is subjected to reprecipitation treatment to remove low-molecular components and residual compound (I) therefrom, thereby increasing Mn and reducing compound (I) (I) residues.

[0087] The term "reprecipitation treatment" as used herein refers to the collection by filtration of the composition of the present invention from which the composition of the present invention has been removed by adding a poor solvent (a solvent in which the composition of the present invention is substantially insoluble) to the reaction solvent In the reaction mixture which was ...

Embodiment 1

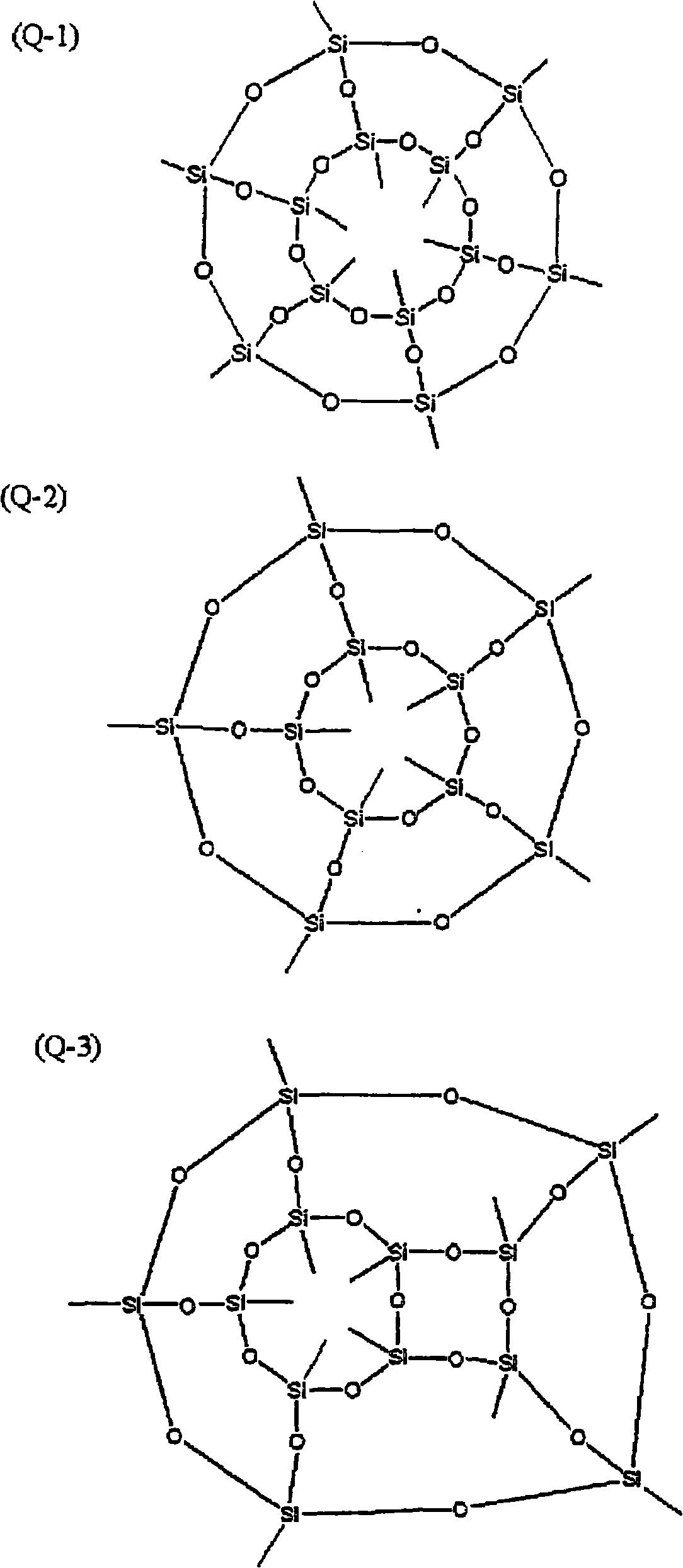

[0157] To 361g of ethyl acetate, add 1g of 8 H 2 C=CH-Si(O 0.5 ) 3 Cage silsesquioxane composed of units, 10 H 2 C=CH-Si(O 0.5 ) 3 A caged silsesquioxane consisting of units and 12 H 2 C=CH-Si(O 0.5 ) 3 A mixture of cage silsesquioxanes composed of cells (model: OL1170, product of Hybrid Plastics), and the resulting mixture was heated to reflux in a nitrogen stream (internal temperature: 78° C.). As a polymerization initiator, a solution obtained by diluting 4 µl of "Luperox 11" (trade name; product of ARKEMA YOSHITOMI, ten hours-half-life temperature: 58°C) with 4 ml of ethyl acetate was added dropwise over 5 hours. After the dropwise addition was complete, the reaction mixture was heated to reflux for 2 hours. After cooling to room temperature, the mixture was concentrated under reduced pressure to a liquid weight of 2 g. Then, 20 ml of methanol was added, and the mixture was stirred for 1 hour. The reaction mixture was filtered and dried to give 0.95 g of a solid....

Embodiment 2

[0162] To 52.8 g of butyl acetate, 1 g of Example Compound (I-d) (product of Aldrich) was added. While heating to reflux (internal temperature: 127°C) in a nitrogen stream, 4 mg of "V-601" (trade name; product of Wako Pure Chemical Industries, ten hours-half-life temperature: 66°C) was added dropwise over 2 hours. ) was diluted with 4 ml of butyl acetate as a polymerization initiator. After the addition was complete, the reaction mixture was heated to reflux for 1 hour. As a polymerization inhibitor, 20 mg of 4-methoxyphenol was added. After cooling to room temperature, the mixture was concentrated under reduced pressure to a liquid weight of 2 g. Then, 20 ml of methanol was added, and the mixture was stirred for 1 hour. The solid was collected by filtration and dried. This solid was dissolved in 10 ml of tetrahydrofuran. While stirring, 1.8 ml of water were added dropwise. After stirring for 1 hour, the supernatant was removed by decantation, and 10 ml of methanol was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle | aaaaa | aaaaa |

| Decomposition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com