Samarium doping gadolinium aluminate base fluorescent powder body and preparation method thereof

A fluorescent powder and alumina technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of easy introduction of impurities, high heat treatment temperature, etc., and achieve the effect of simple and easy process, uniform particle size distribution, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

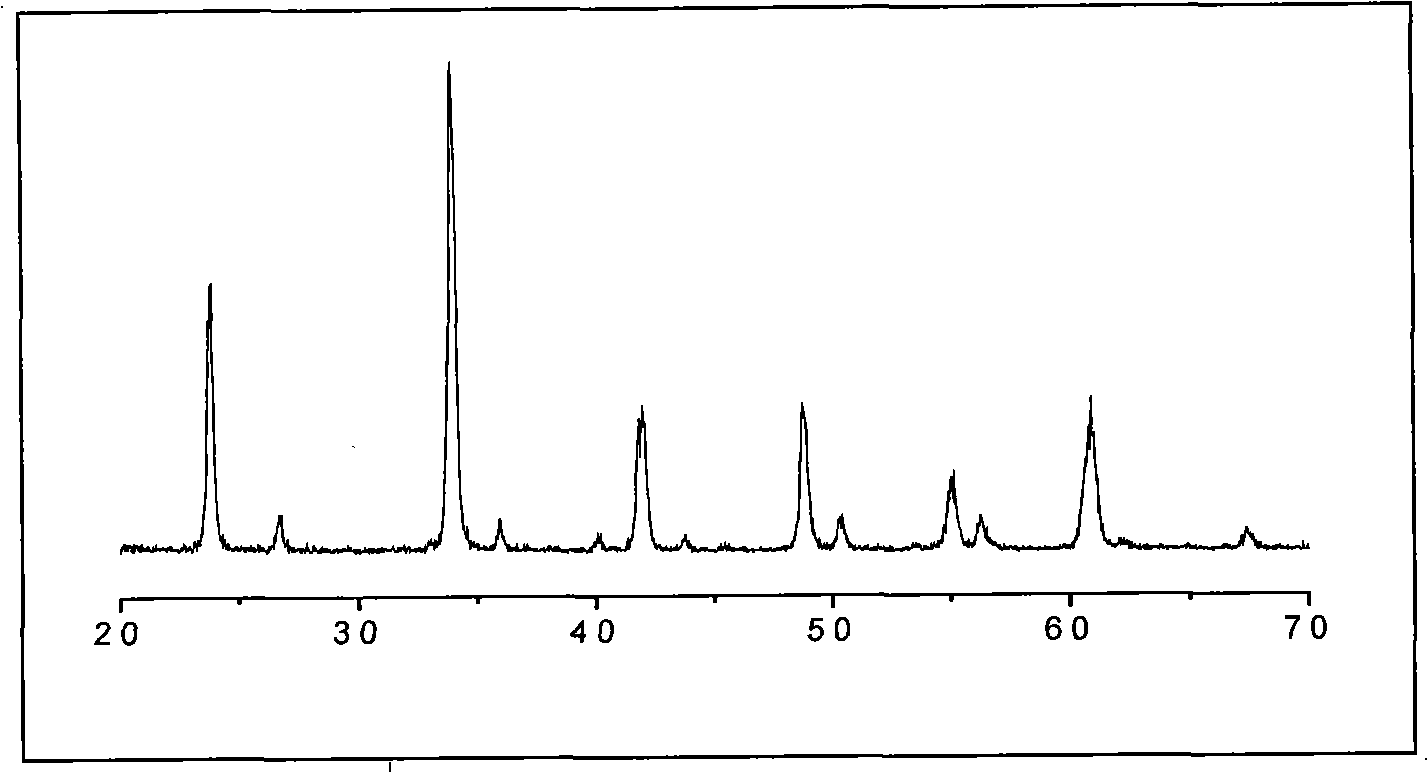

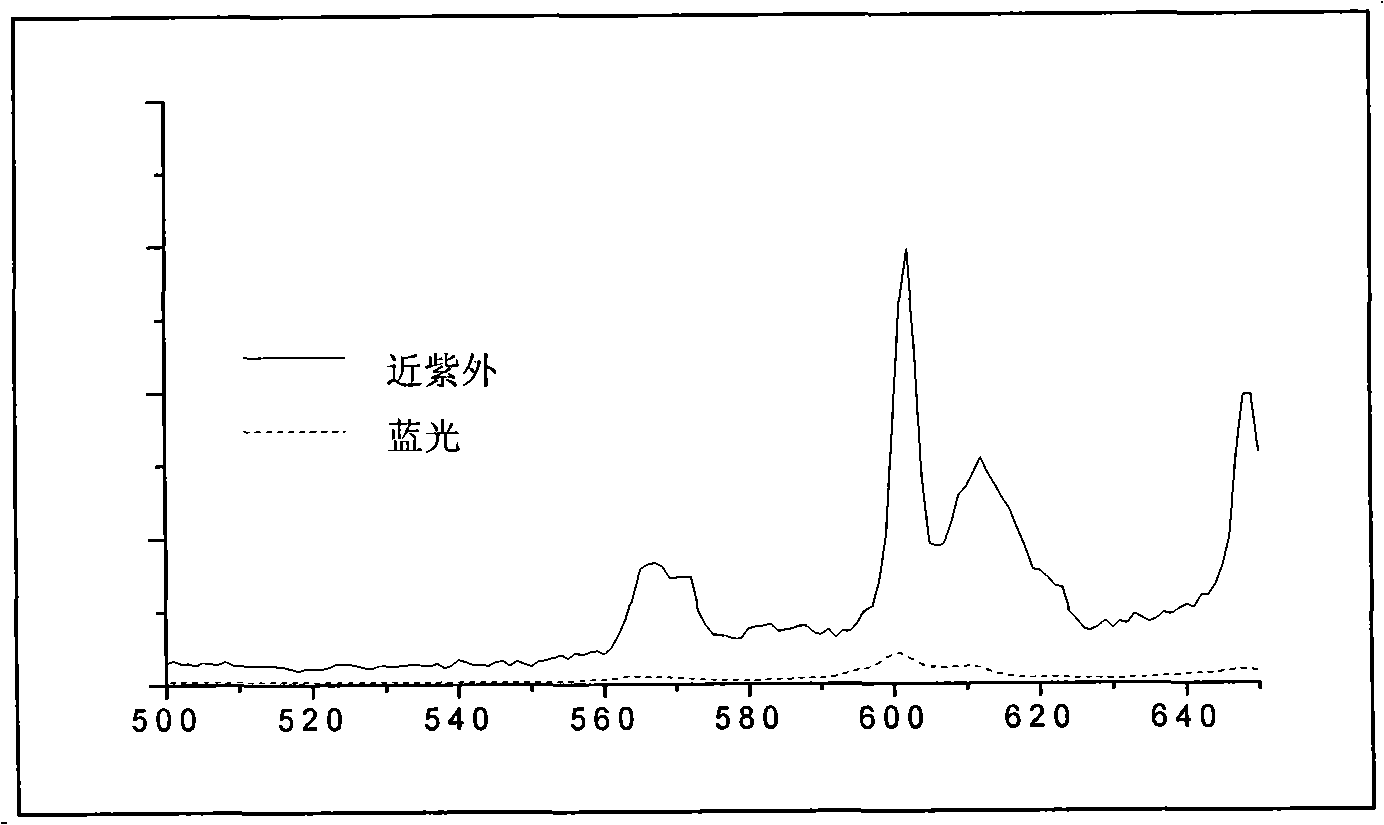

[0019] Get 7.252g gadolinium oxide, 0.6976g samarium oxide and dissolve in the acetic acid that 50ml concentration is 0.2mol / L, temperature is 65 ℃; Get 15.006g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) Dissolve in the above solution and stir until uniform; then add 7.44g of ethylene glycol, stir and evaporate the solution at 70°C to obtain a white transparent gel; grind the dried gel powder, and pre-calcine at 600°C for 3 hours in an air atmosphere , the heating rate is 4°C / min; after grinding the calcined powder, it is sintered at 1000°C for 4h in the air atmosphere to obtain the final product GdAlO 3 :Sm 0.1 . The XRD pattern of the prepared powder is figure 1 , near-ultraviolet / blue light excitation spectrum such as figure 2 shown.

Embodiment 2

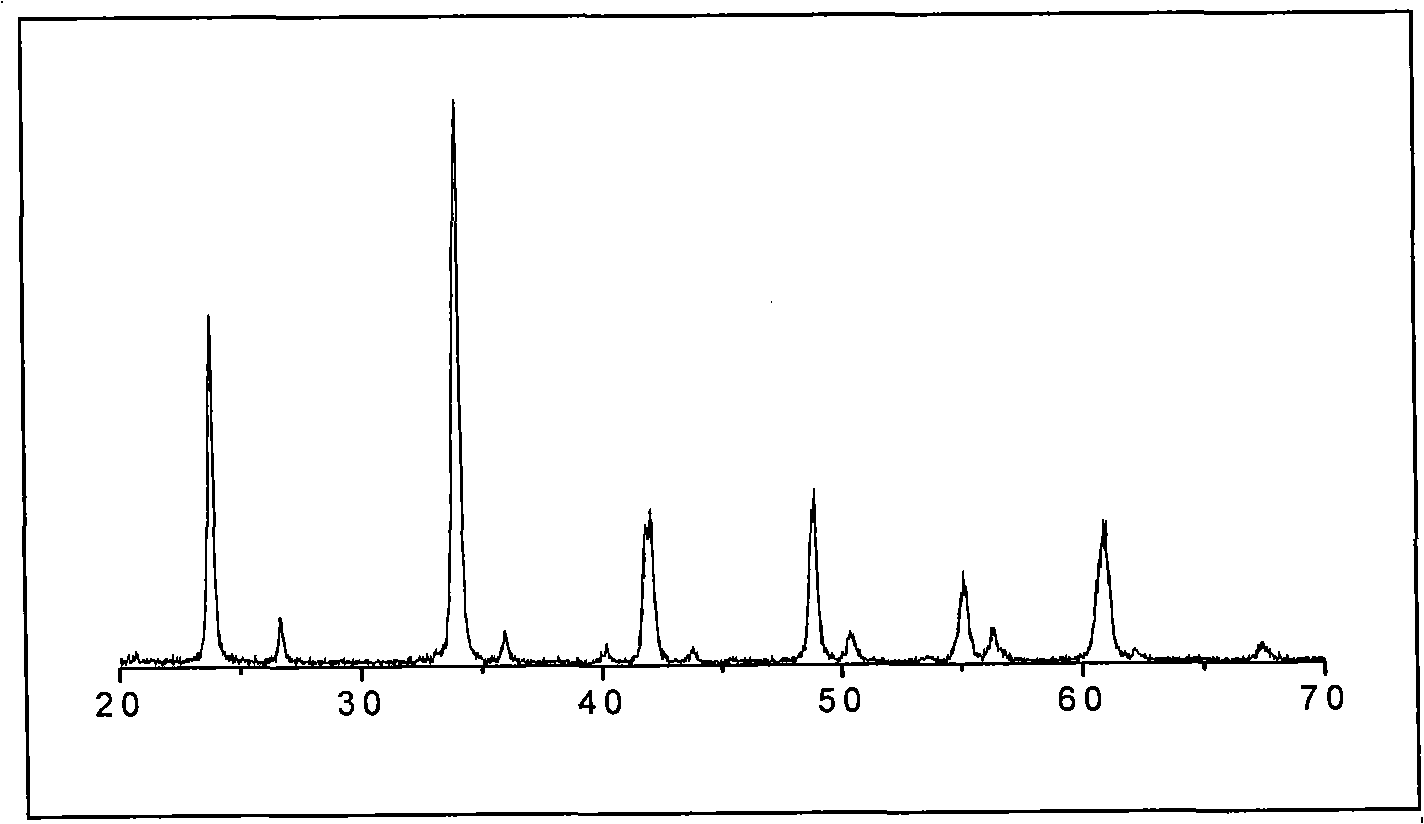

[0021] Get 7.252g gadolinium oxide, 0.3488g samarium oxide and dissolve in the acetic acid that 50ml concentration is 0.3mol / L, temperature is 60 ℃; Get 15.006g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) Dissolve in the above solution and stir until uniform; then add 14.88g of ethylene glycol, stir and evaporate the solution at 65°C to obtain a white transparent gel; grind the dried gel powder, and pre-calcine at 700°C for 2.5 h, heating rate 5°C / min; after grinding the calcined powder, sintering at 1300°C for 4h in air atmosphere to obtain the final product GdAlO 3 :Sm 0.05 . The XRD pattern and near-ultraviolet / blue light excitation pattern of the prepared powder are similar to Example 1.

Embodiment 3

[0023] Get 7.252g gadolinium oxide, 0.6976g samarium oxide, 0.0746g dysprosium oxide and be dissolved in 50ml concentration and be 0.25mol / L, the temperature is in the acetic acid of 70 ℃; Get 15.006g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) Dissolve in the above solution and stir until uniform; then add 11.16g of ethylene glycol, stir and evaporate the solution at 65°C to obtain a white transparent gel; grind the dried gel powder, and pre-calcine at 800°C for 3h in an air atmosphere , the heating rate is 3°C / min; after grinding the calcined powder, it is sintered at 1200°C for 3h in the air atmosphere to obtain the final product GdAlO 3 :Sm 0.1 Dy 0.01 . The XRD pattern and near-ultraviolet / blue light excitation pattern of the prepared powder are similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com