Inducement and preparation of S. keratinase and method for sorting wool by using the same

A technology of keratinase and wool, which is applied in the field of S. keratinase induction, production and use to finish wool, can solve the problems of unreached, discounted industrial production prospects, etc., achieve mechanical strength improvement, easy industrialization promotion, and save treatment The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using Stenotrophomonas maltophilia DHHJ as the original strain and using wool as the inducer, the optimal culture conditions were determined through orthogonal experiments, and its induction and domestication culture: wool 2g, sodium chloride 0.4g , 0.4 g of disodium hydrogen phosphate, 0.03 g of potassium dihydrogen phosphate, 100 ml of water, pH=7.5, 40° C., constant temperature culture for 2 to 3 days.

[0026] After several times of domestication, high-efficiency and stable strains were obtained, and the following culture ratios were used for amplified culture: chicken feather 2g, sodium chloride 0.4g, disodium hydrogen phosphate 0.4g, potassium dihydrogen phosphate 0.03g, water 100ml, pH= 7.5, 40° C., constant temperature culture for 72 hours to obtain enzyme-containing culture solution.

Embodiment 2

[0028] After centrifugation, salting-out, standing, re-centrifugation, purification and concentration of the obtained enzyme-containing culture solution, the wool is treated and detected by a 280nm ultraviolet spectrophotometer and a microscope to obtain the optimal treatment conditions: enzyme concentration 3% (owf), pH=7.8, treated at 40°C for 75min.

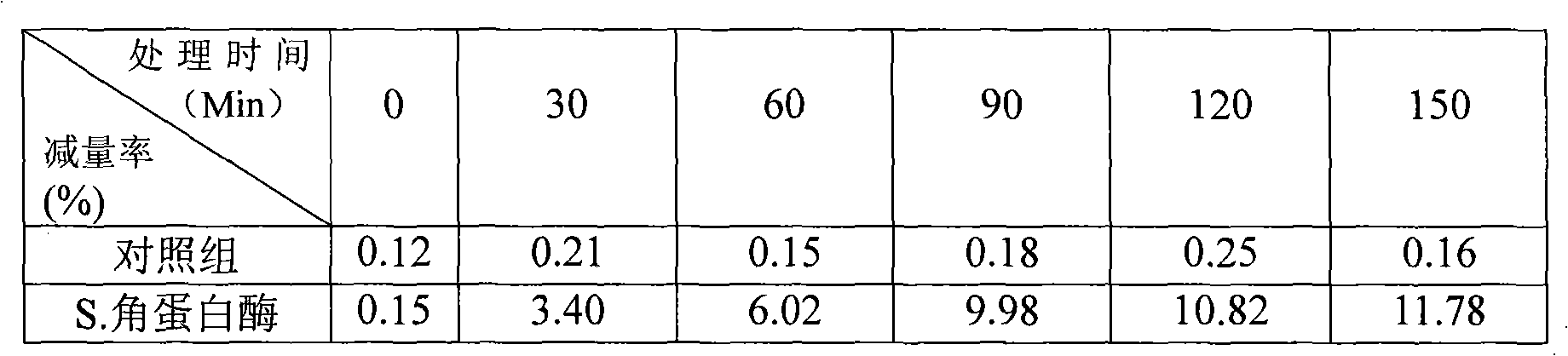

[0029] Measure parameters such as weight reduction rate, felt shrinkage rate, alkali solubility, strength, whiteness, etc., to prove its macroscopic treatment effect on wool.

Embodiment 3

[0031] After the wool fiber was treated with S. keratinase, the changes of weight reduction rate, felt shrinkage rate, alkali solubility, strength and whiteness were analyzed. Discuss the mode of action of S. keratinase on wool, the influence coefficient on fiber damage and fabric strength and the feasibility of large-scale application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com