Preparation for ZnO quantum dot

A technology of quantum dots and pulling method, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of long growth time, superior performance of quantum dot lasers, uncontrollable growth, etc., to improve uniformity, size uniformity and quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

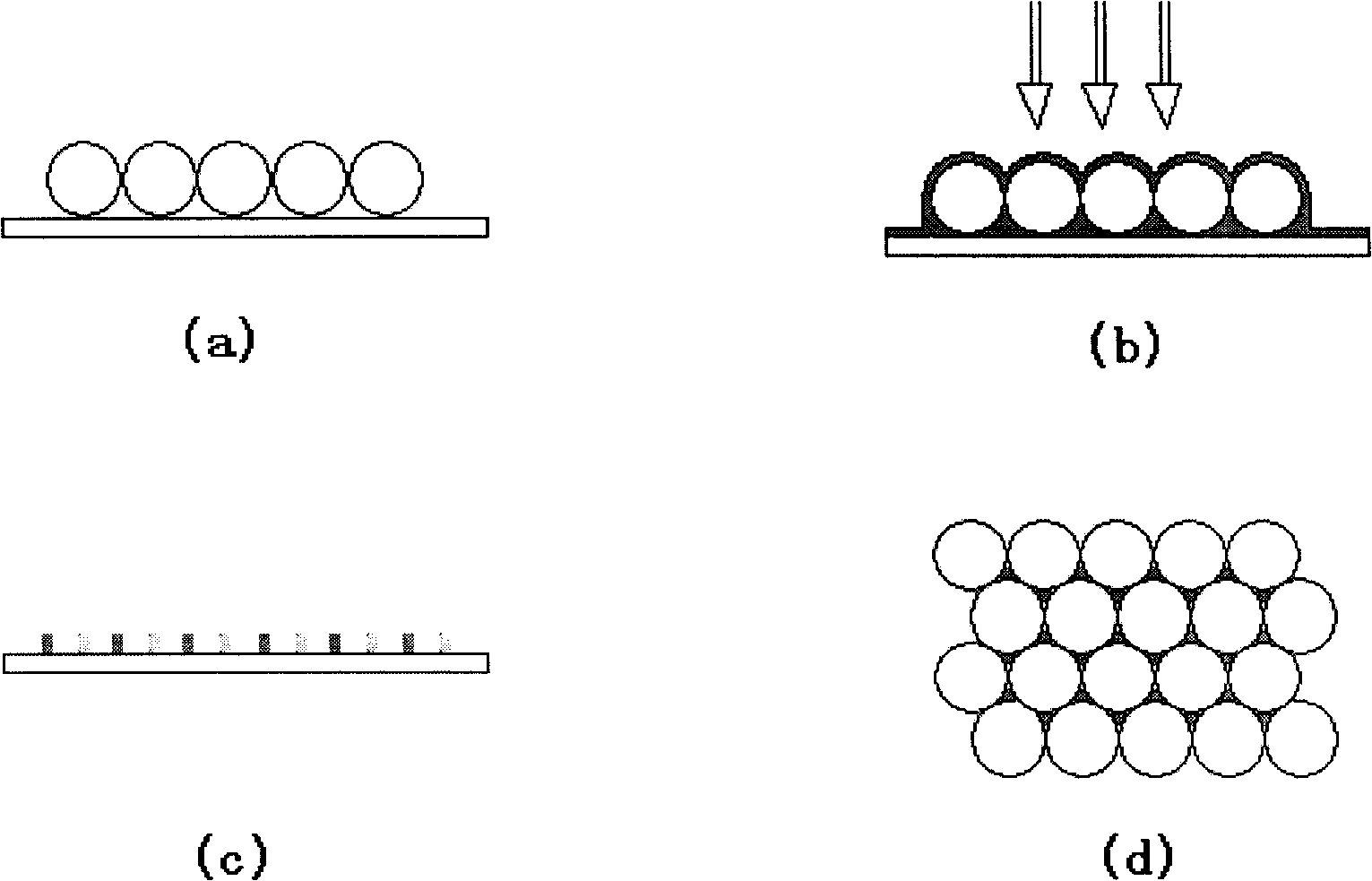

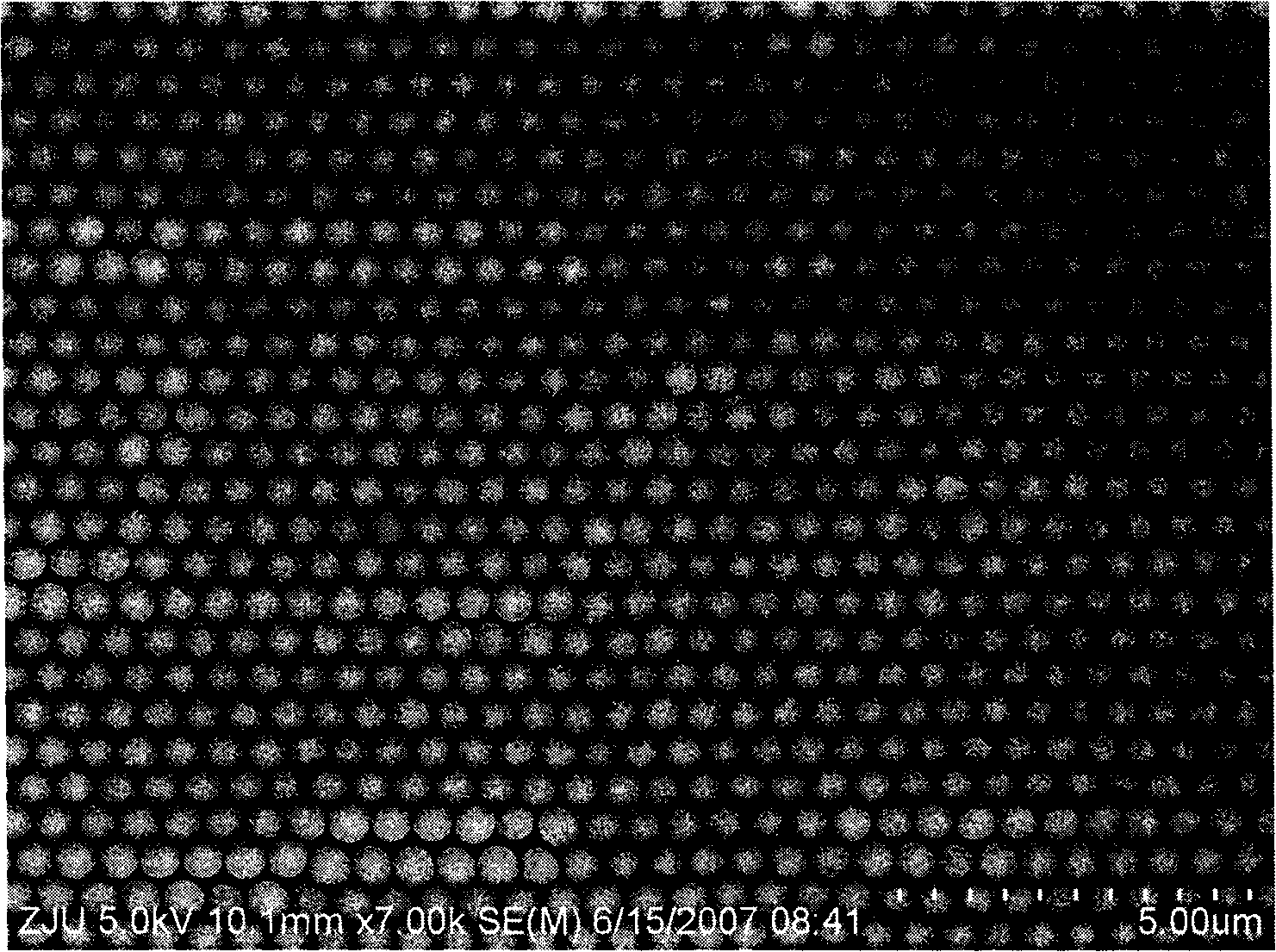

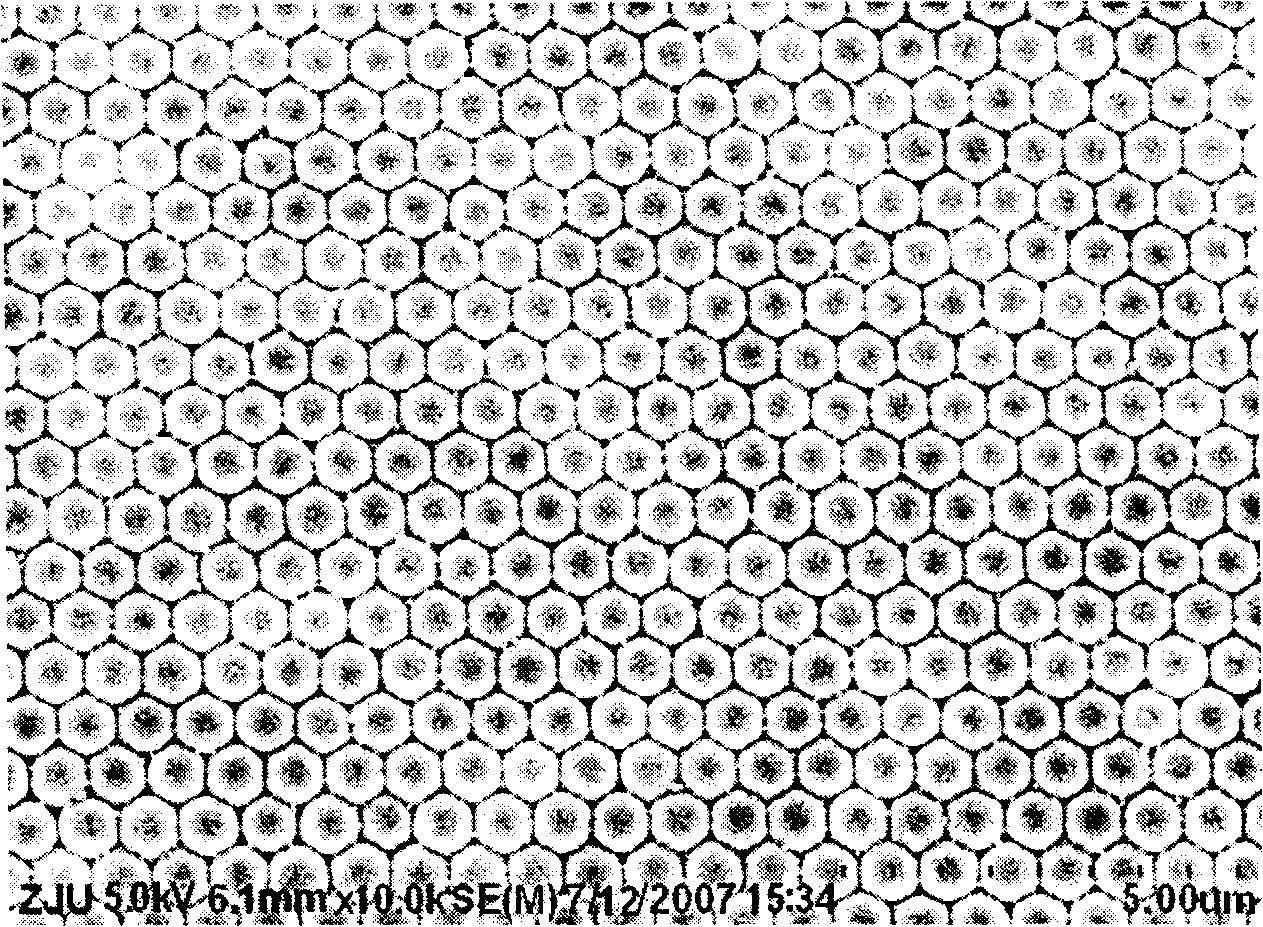

[0022] First for 1×1cm 2 The low-doped n-Si sheet with a size of (100) plane was ultrasonically cleaned, and then the volume ratio was 1:1 in H 2 SO 4 +H 2 o 2 The mixed solution was boiled for ten minutes, followed by NH at a volume ratio of 3:1 4 OH+H 2 o 2 Ultrasonic vibration in the mixed solution for 30 minutes, the temperature is 80 ° C, the purpose is to improve the hydrophilicity of the substrate and the flatness of the surface, and then use a dropper to take 2-3 drops of polystyrene nanoparticles with a concentration of 10% and a diameter of 600nm. Drop the suspension of balls on the surface of the treated silicon wafer, let the balls cover the whole substrate uniformly and densely, and then slowly immerse the ball-covered substrate into deionized water. At this time, a single layer of hexagonal close-packed spheres is formed on the substrate and the water surface. In order to prevent the spheres on the water surface from depositing on the substrate again when t...

Embodiment 2

[0027] First the substrate is 1×1cm 2 Low-doped n-Si flakes with large and small (100) planes are subjected to the same surface treatment, using a monodisperse suspension of nanospheres with a concentration of 10% and a diameter of 100nm. The assembled nanospheres were used as templates for the preparation of ZnO quantum dots; -6 Under the condition of Torr, a 5nm thick ZnO thin film was deposited by electron beam evaporation; finally soaked in toluene and ultrasonically vibrated for 2min to remove the nanospheres in the template.

Embodiment 3

[0029] First the substrate is 1×1cm 2 Low-doped n-Si flakes with large and small (100) planes are subjected to the same surface treatment, using a monodisperse suspension of nanospheres with a concentration of 10% and a diameter of 1000 nm, and the same pull method is used to form a monolayer self-assembled nanospheres; then at room temperature, a vacuum of 10 -4 Under the condition of Torr, a 50nm thick ZnO thin film was deposited by electron beam evaporation; finally soaked in toluene and ultrasonically vibrated for 5min to remove the nanospheres in the template.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com