Method for processing nitrobenzene and aniline waste water

A technology for aniline wastewater and nitrobenzene, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as poor safety, high treatment cost, and difficult sludge disposal , achieve strong impact load resistance, remove ammonia nitrogen and total nitrogen, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

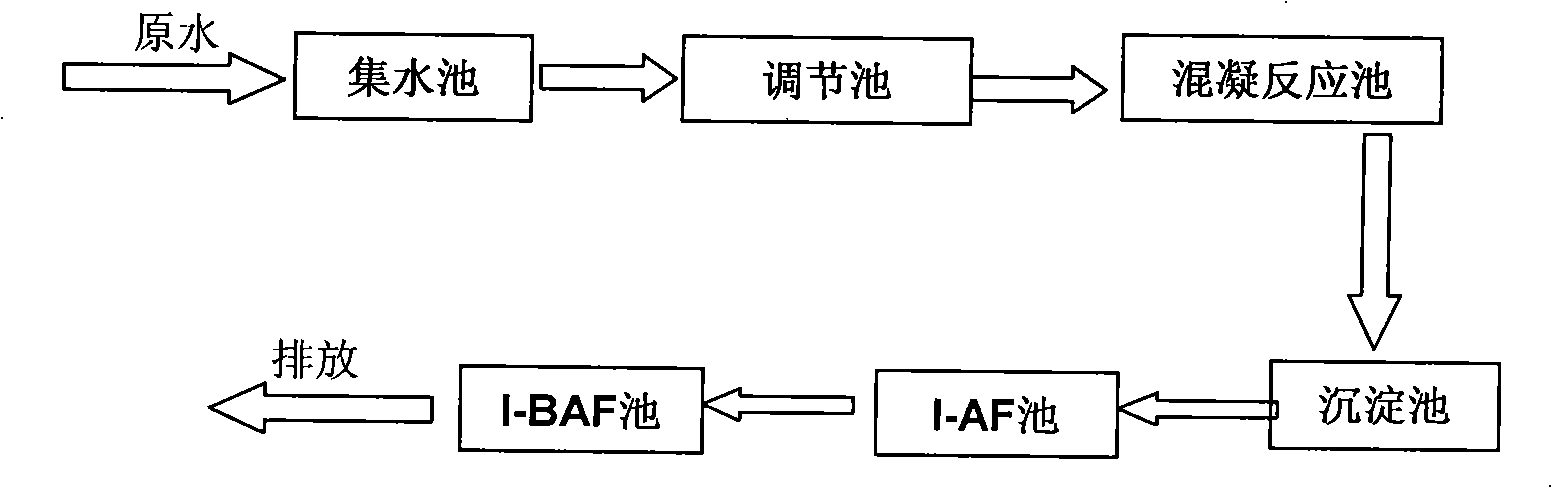

Image

Examples

Embodiment 1

[0028] The present invention is used to treat nitrobenzene and aniline waste water from a company’s organic chemical plant. The raw water COD concentration is 2000mg / L, nitrobenzene concentration is 100mg / L, aniline concentration is 500mg / L, petroleum is 100mg / L, and the treatment capacity is 1200m 3 / d, the water temperature in the I-AF reactor and I-BAF reactor is controlled at 20°C-40°C, the hydraulic retention time is 13h and 16h respectively, the final effluent COD concentration is 100mg / L, and the nitrobenzene concentration is 2mg / L , the concentration of aniline is 1mg / L and that of petroleum is 8mg / L.

Embodiment 2

[0030] Using the present invention to treat nitrobenzene and aniline wastewater from a polyurethane joint-stock company, the raw water COD concentration is 2000-3500mg / L, the nitrobenzene concentration is 150-300mg / L, the aniline concentration is 400-800mg / L, and the treatment capacity is 480m 3 / d, the water temperature in the I-AF reactor and I-BAF reactor is controlled at 20°C-40°C, the hydraulic retention time is 20h and 26h respectively, the final effluent COD concentration is 30-150mg / L, and the nitrobenzene concentration is 0.5 -2mg / L, the concentration of aniline is 0.2-1mg / L.

Embodiment 3

[0032] Using the present invention to treat nitrobenzene and aniline wastewater of a certain company, the COD concentration of the raw water is 2000-4200mg / L, the nitrobenzene concentration is 100-300mg / L, the aniline concentration is 600-1000mg / L, and the chlorobenzene concentration is 50-100mg / l, the concentration of formaldehyde is 100-200mg / l, the concentration of chloride ion is 10000-30000mg / l, and the processing capacity is 1000m 3 / d, the water temperature in the I-AF reactor and I-BAF reactor is controlled at 20°C-40°C, the hydraulic retention time is 26h and 30h respectively, the final effluent COD concentration is 30-100mg / L, and the nitrobenzene concentration is 1mg / L, the concentration of aniline is 0.3-0.7mg / L.

[0033] It can be seen from the above examples that the present invention has good treatment effects on nitrobenzene and aniline wastewaters of different water qualities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com