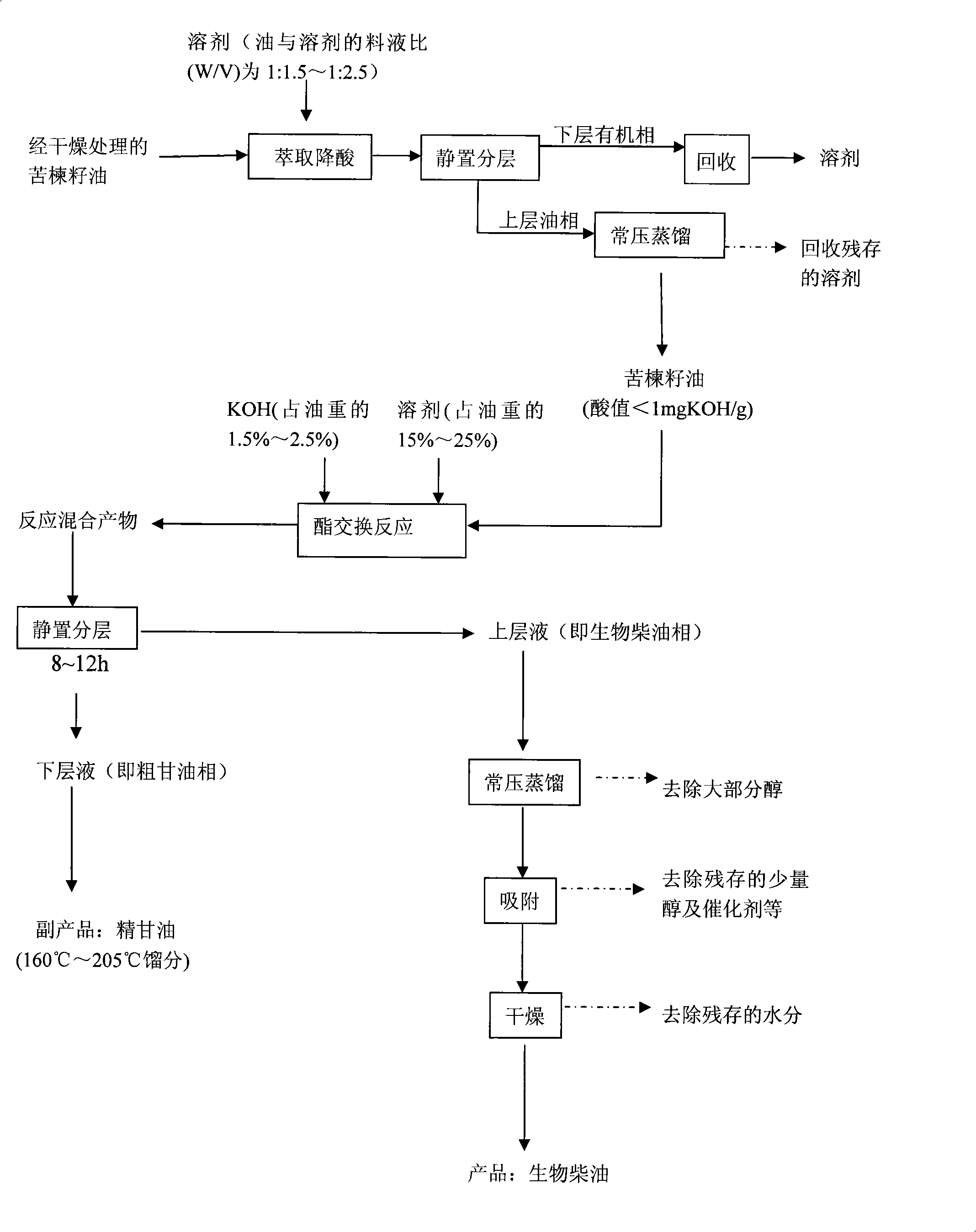

Process for preparing biodiesel from chinaberry seed oil

A technology of biodiesel and neem seeds, which is applied in the direction of biofuel, biological raw material, fat oil/fat refining, etc., can solve the problem of conversion rate of polluted environment, etc., and achieve the effect of improving the process and comprehensive utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Pretreatment stage: Weigh 1000g of dried neem seed oil, preheat to 30°C in a vacuum constant temperature reactor, preheat 2500mL of anhydrous methanol to the same temperature and add it to the reactor, slowly stir and extract for 20min, Extract 3 times, transfer the reaction product to a separatory funnel and let it stand for stratification, recover the methanol phase in the lower layer, transfer the oil phase in the upper layer to the distillation bottle of the rotary evaporator, and keep it under the condition of 70°C and 100r / min. Distill under pressure to recover the residual methanol, then dry with anhydrous sodium sulfate, and vacuum filter to remove sodium sulfate to obtain neem seed oil with low acid value.

[0021] (2) Transesterification reaction: Weigh 1000g of pretreated neem oil and transfer it to a vacuum constant temperature reaction kettle, install the reaction kettle, and preheat the oil to the reaction temperature of 55°C, add fully miscible And be...

Embodiment 2

[0025] (1) Pretreatment stage: Weigh 1000g of dried neem seed oil, preheat to 35°C in a vacuum constant temperature reactor, preheat 2000mL of absolute ethanol to the same temperature and add it to the reactor, slowly stir and extract for 15min, Extract 4 times, transfer the reaction product to a separatory funnel and let it stand for stratification, recover the lower ethanol phase, transfer the upper oil phase to the distillation bottle of the rotary evaporator, and store it under normal pressure at 80°C and 120r / min. Distill and recover the remaining ethanol, then dry it with activated alumina, and vacuum filter the activated alumina to obtain neem oil with low acid value.

[0026] (2) Transesterification reaction: Weigh 1000g of pretreated neem seed oil and transfer it to a vacuum constant temperature reactor, install the reactor, and preheat the oil to the reaction temperature of 65°C, add fully miscible And be preheated to the KOH-ethanol solution (wherein containing 16g ...

Embodiment 3

[0030] (1) Pretreatment stage: Weigh 1000g of dried neem seed oil, preheat to 40°C in a vacuum constant temperature reactor, preheat 1500mL of anhydrous methanol to the same temperature and add it to the reactor, slowly stir and extract for 10min, Extract 5 times, transfer the reaction product to a separatory funnel and let it stand for stratification, recover the methanol phase of the lower layer, transfer the upper oil phase to the distillation bottle of the rotary evaporator, and store it under normal pressure at 70°C and 100r / min. Distill and recover the remaining methanol, then dry it with anhydrous sodium sulfate, and vacuum filter to remove sodium sulfate to obtain neem seed oil with low acid value.

[0031] (2) Transesterification reaction: Weigh 1000g of pretreated neem oil and transfer it to a vacuum constant temperature reaction kettle, install the reaction kettle, and preheat the oil to the reaction temperature of 45°C, add fully miscible And be preheated to the KO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com