Surface graft modification biodegradable bioabsorbable polyester superfine fibre, and preparation, apparatus and use thereof

A surface graft modification and biodegradation technology, applied in the field of surface modified polymer microfiber membranes, can solve the problems of material surface etching, inability to achieve uniform modification, and achieve good biocompatibility and shape retention. appearance, the effect of good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

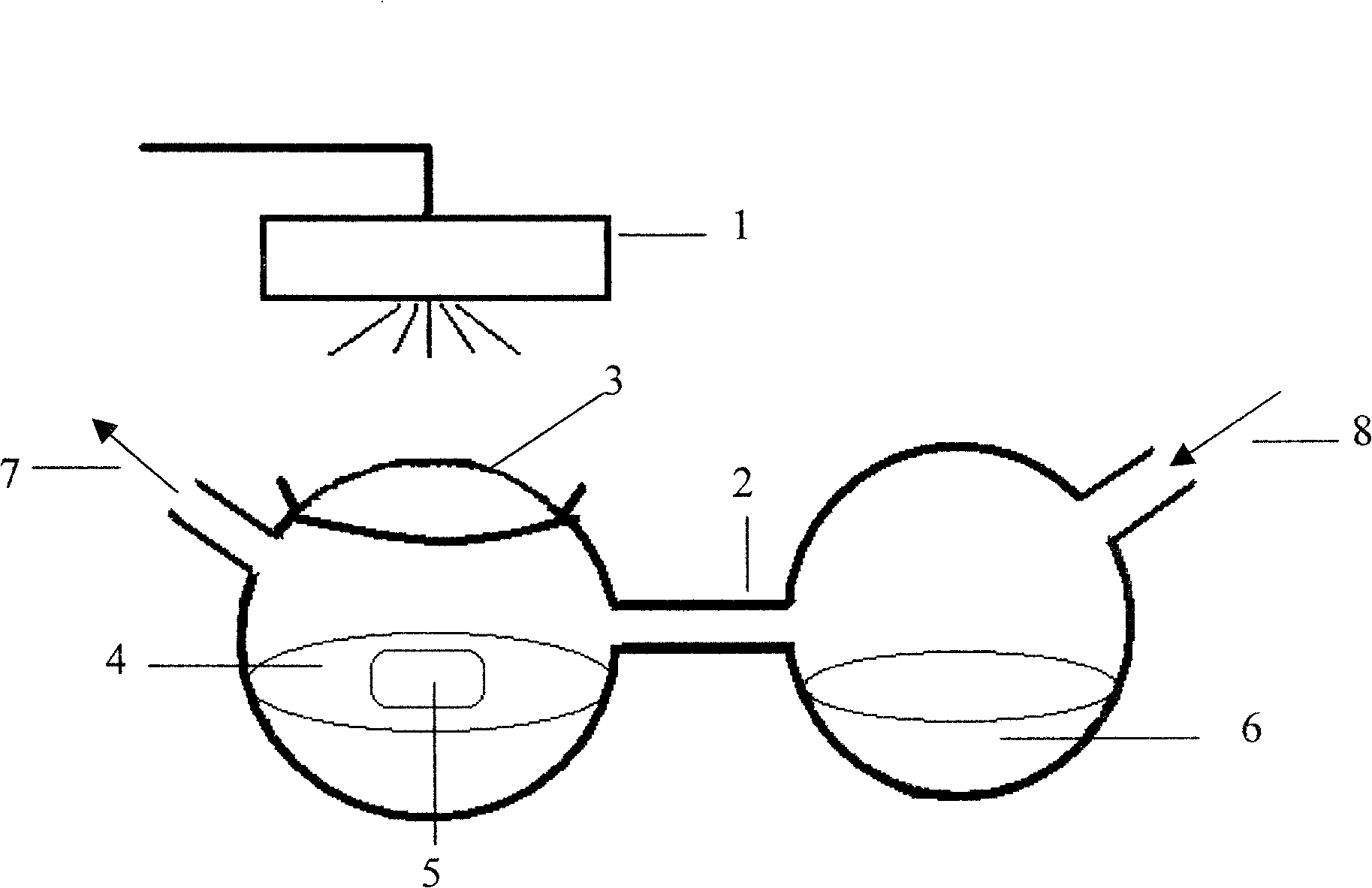

[0059] For the grafting reaction device that can be used to prepare the biodegradable and absorbable polyester microfiber membrane modified by surface grafting of the present invention, please refer to figure 1 .

[0060] A glass connecting two-body reaction connecting device 2, one end of the connecting two-body reaction connecting device is a container with an opening, and the other end is a container without an opening; there is a Teflon with a hole in the open container Long original plate 4, and the teflon original plate is positioned at below the communicating pipe that communicates with the two-body reaction connector, and the hole of the teflon original plate is polyester microfiber membrane material or composite ultrafine fiber membrane 5, one can see through The ultraviolet quartz cover 3 is covered on the opening of the container, and the vacuum pump interface 7 of the container is connected with the vacuum pump through a pipeline; grafted functional monomers and in...

Embodiment 2

[0071] The equipment is the same as in Example 1.

[0072] (1) Polycaprolactone (PCL) is prepared into a PCL ultrafine fiber membrane with a fiber diameter of 200nm by an electrospinning process;

[0073] (2) the microfiber membrane prepared by step (1) polymer material polycaprolactone (PCL) is horizontally put into one of the Teflon discs with holes in it of a connected two-body reaction connector (grafting reaction device) The container is placed in the hole in the middle of the Teflon plate, and then the open container is covered with a quartz cover that can pass through ultraviolet rays and is coated with vacuum ester on the joint part of the container;

[0074] (3) preparation of grafting monomer and initiator mixed solution: preparation maleic anhydride and benzophenone mol ratio are 80: 1 mixed solution 40ml, mix homogeneously, place mixed solution in step ( 2) in another container in the connected two-body reaction connector;

[0075] (4) the air in the reactor of s...

Embodiment 3

[0082] The equipment is the same as in Example 1.

[0083] (1) Poly(lactic acid-glycolic acid) copolymer (PLGA) is prepared into a polyester ultrafine fiber membrane with a fiber diameter of 1000 nm by electrospinning process;

[0084] (2) Put the microfiber membrane prepared by the polymer material poly(lactic acid-glycolic acid) copolymer (PLGA) in step (1) horizontally into one of the connected two-body reaction connectors (grafting reaction device) with holes In the container of the Teflon disk, it is placed in the hole in the middle of the Teflon disk, and then the open container is covered with a quartz cover that can pass through ultraviolet rays and is coated with vacuum ester on the joint part of the container;

[0085] (3) Preparation of grafted monomer and initiator mixed solution: prepare N-vinylpyrrolidone and benzophenone molar ratio as 20: 1 mixed solution 40ml, mix well, place mixed solution in reactor through reactor Step (2) is connected in another container...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com