Preparation process for nano-scale chitosan and latex graft copolymer

A technology of graft copolymer and preparation process, applied in the field of preparation technology of nano-scale chitosan and latex graft copolymer, can solve the problems of high cost, short duration of antibacterial antibacterial, poor combination of antibacterial agent and latex, etc. , to achieve the effect of short cycle, long antibacterial efficacy and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

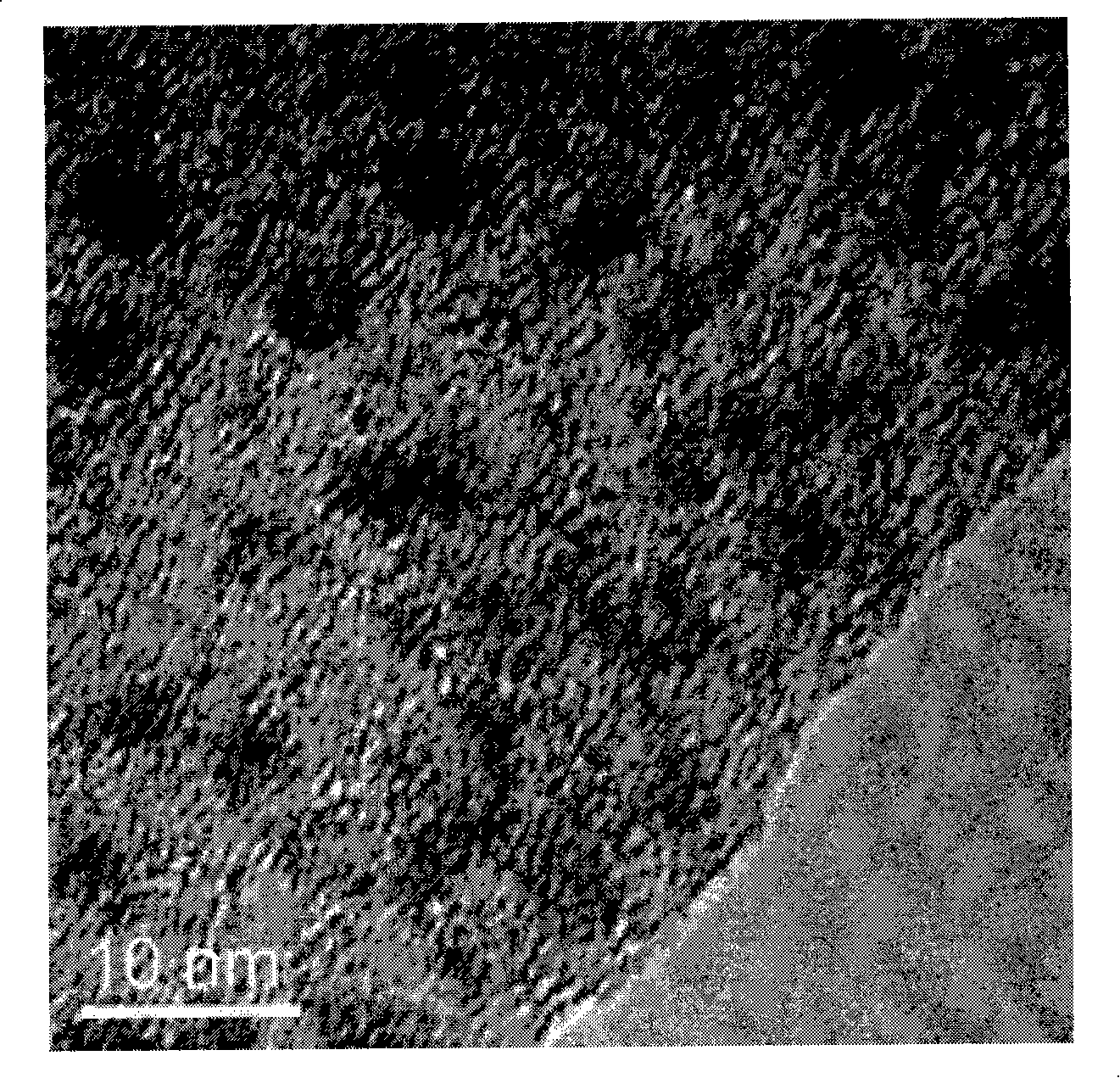

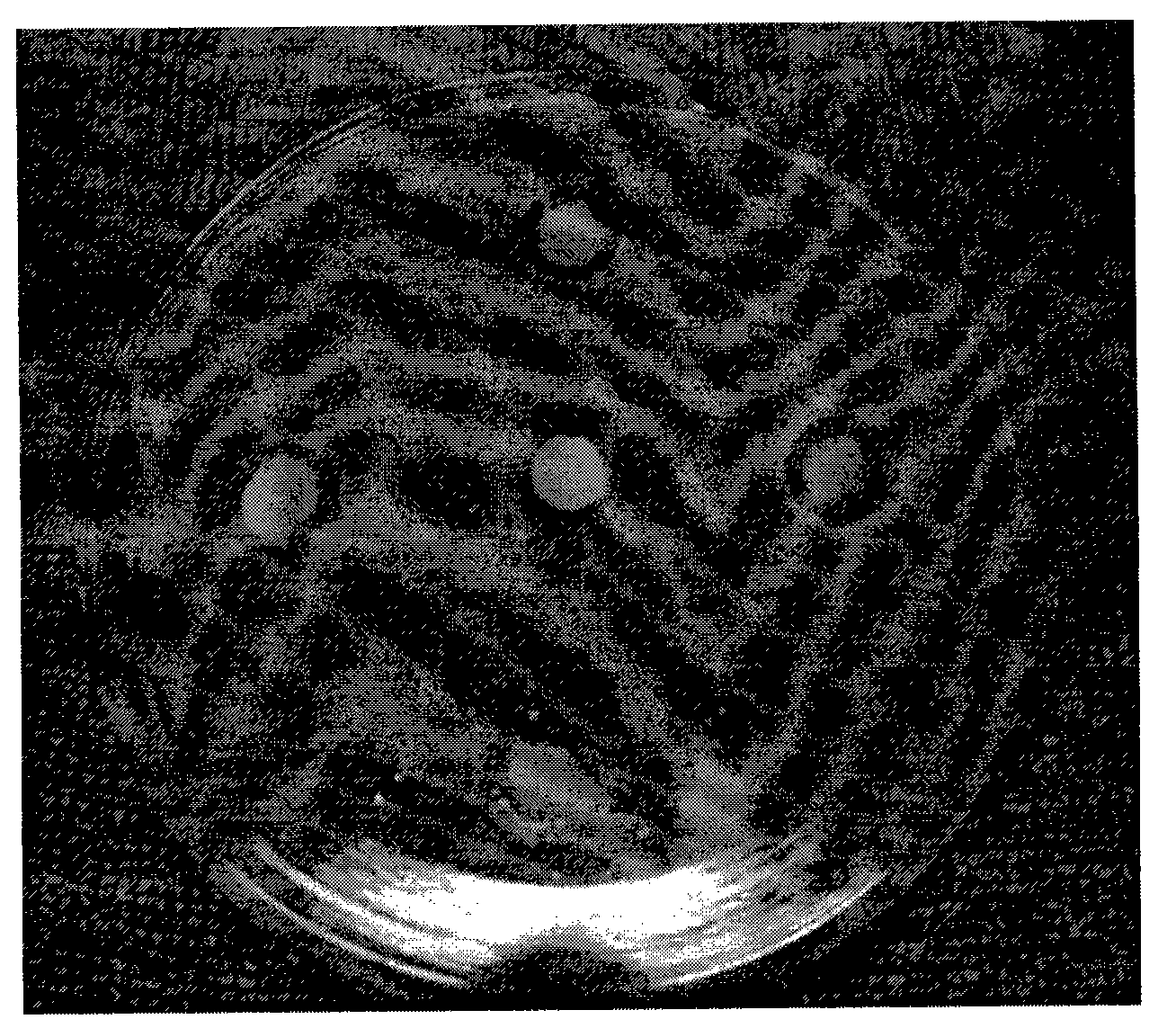

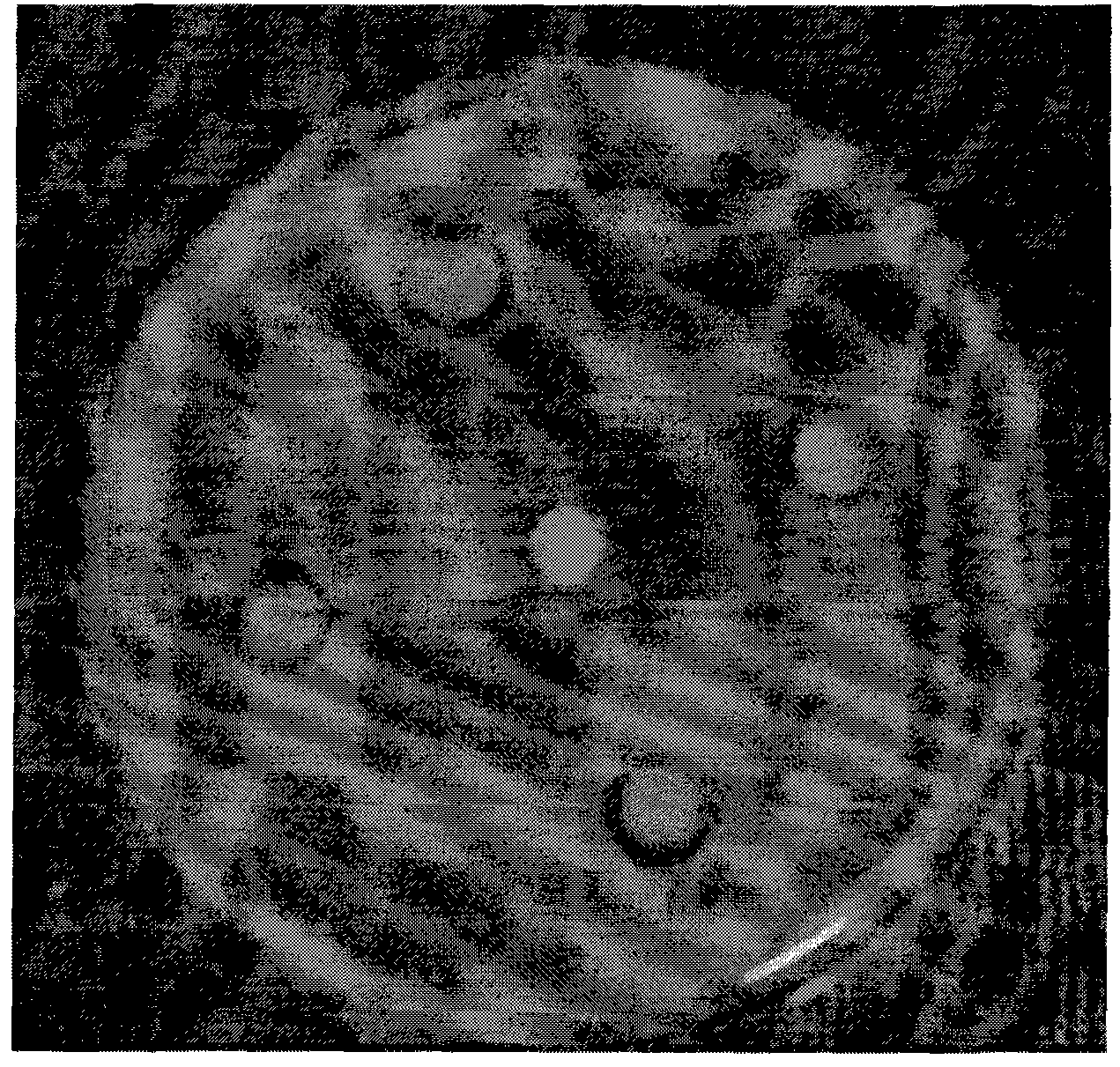

Image

Examples

Embodiment 1

[0028] Dissolve 0.04g of chitosan in 20ml of 2% acetic acid solution, place on a magnetic stirrer and stir for 40 minutes; after standing for 5min to defoam, add 6.7mg of dispersant sodium polyphosphate until the solution is milky white; Sodium solution adjusts the pH of the solution to 5.0-6.0, and then adjusts the pH to 8.5-9.0 with ammonia water; filter the latex with a 400-mesh standard sieve. Take 10ml nano-sized chitosan, pass through N 2 , add 0.05g cerium ammonium nitrate (CAN) and 10ml latex in turn, adjust the pH to 9.0 with ammonia water, add cumene hydroperoxide solution, stir at room temperature at 400r / min, add tetraethylenepentamine dropwise, and react for 15h.

Embodiment 2

[0030] According to the processing method of embodiment 1, the difference of embodiment 2 is: the molar mass ratio of chitosan and latex is 1: 2, and the stirring speed is 200r / min.

Embodiment 3

[0032] According to the processing method of embodiment 1, the difference of embodiment 3 is: use potassium persulfate as initiator; the molar mass ratio of chitosan and latex is 1: 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com