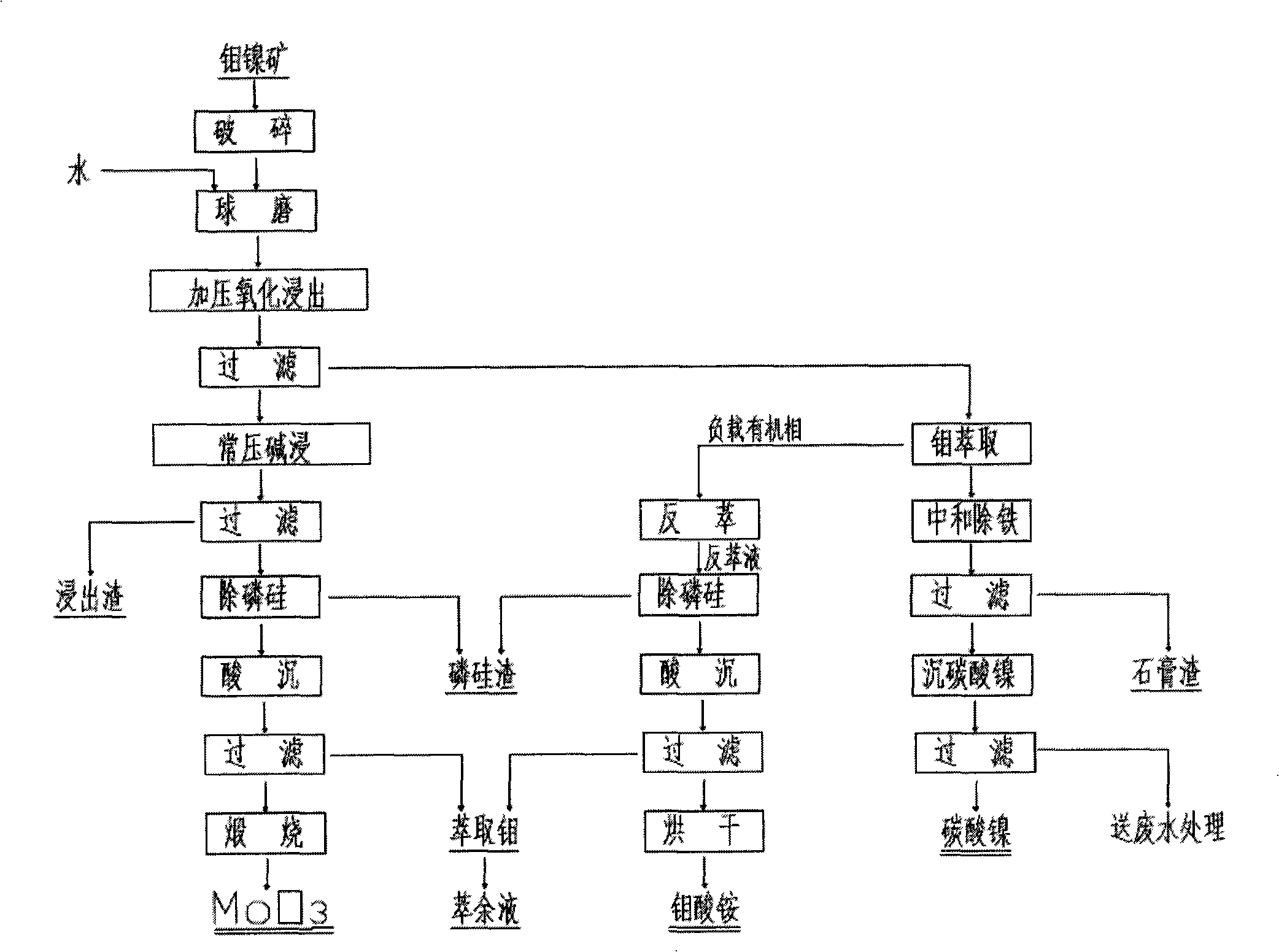

Method for extracting molybdenum and nickel by molybdenum nickel ore whole wet method

A technology of molybdenum-nickel ore and full-wet method, which is applied in the field of full-wet extraction of molybdenum-nickel from black rock series molybdenum-nickel ore, which can solve the problems of high chlorine-containing wastewater treatment costs, high production costs, and environmental pollution. Clean and environmentally friendly, low processing cost, and mild pressure oxidation leaching conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 100g of finely ground molybdenum ore and 500ml of water into a GSA type 2L vertical titanium-lined autoclave. The main components of the molybdenum ore are: 5.4% molybdenum, 2.3% nickel, and 19.7% sulfur. Heat to 140°C, feed oxygen, oxygen partial pressure is 0.3MPa, control the oxidation leaching reaction temperature 150°C, and react for 3 hours. During the pressure leaching process, no other additives and catalysts are needed except oxygen. After the reaction, The ore pulp was filtered to obtain 490ml leach solution and 68.2g leach slag. The main components of the leach solution were: molybdenum 6.68g / l, nickel 4.62g / l, H 2 SO 4 27.48g / L; main components of leaching slag: molybdenum 3.12%, nickel 0.054%. During the pressure oxidation leaching process, 98.4% of nickel and about 60% of molybdenum enter the leach solution, and the rest of molybdenum enters the leaching residue in the form of molybdenum oxide. The molybdenum in the leaching slag is often recovered ...

Embodiment 2

[0046] Add 100 g of finely ground molybdenum ore and 600 ml of water into a GSA type 2L vertical titanium-lined autoclave. The main components of the molybdenum ore are: molybdenum 6.01%, nickel 2.55%, and sulfur 20.73%. Introduce 0.4MPa oxygen in advance, control the oxidation leaching reaction temperature at 180°C, and react for 3 hours. During the pressurized leaching process, no other additives and catalysts need to be added except oxygen. Composition: molybdenum 5.08g / l, nickel 4.19g / l, H 2 SO 4 31.48g / l), the nickel leaching rate is 98.6% and the molybdenum leaching rate is 49.3% in the pressure oxidation leaching process.

[0047] The molybdenum in the leaching liquid is extracted with tri-isooctylamine extractant in two-stage countercurrent, and the extraction rate of molybdenum reaches 98.5%. up to 98.5%. The magnesium salt precipitation method is used to remove impurities such as silicon, arsenic, and phosphorus in the stripping liquid. After removing phosphorus, ...

Embodiment 3

[0051] Add 100g of finely ground molybdenum ore and 300ml of water into a GSA type 2L vertical titanium-lined autoclave. The main components of the molybdenum ore are: molybdenum 5.71%, nickel 2.45%, and sulfur 21.33%. Introduce 0.2MPa oxygen in advance, control the oxidation leaching reaction temperature at 130°C, and react for 4 hours. During the pressure leaching process, no other additives and catalysts need be added except oxygen. After the reaction, the pulp is filtered to obtain 255ml leachate. Composition: molybdenum 10.08g / l, nickel 8.25g / l, H 2 SO 4 45.48g / L, the nickel leaching rate is 97.7% and the molybdenum leaching rate is 51.2% during the pressure oxidation leaching process.

[0052] The molybdenum in the leaching liquid is extracted with tri-isooctylamine extractant in two-stage countercurrent, and the extraction rate of molybdenum reaches 98.6%. up to 98%. The magnesium salt precipitation method is used to remove silicon, arsenic, phosphorus and other impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com