Agglutinate neodymium-iron-boron magnet and preparation method thereof

A neodymium iron boron and magnet technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as mechanical performance degradation, process and product performance defects, and achieve good mold release and dimensional precision. , the effect of favorable mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

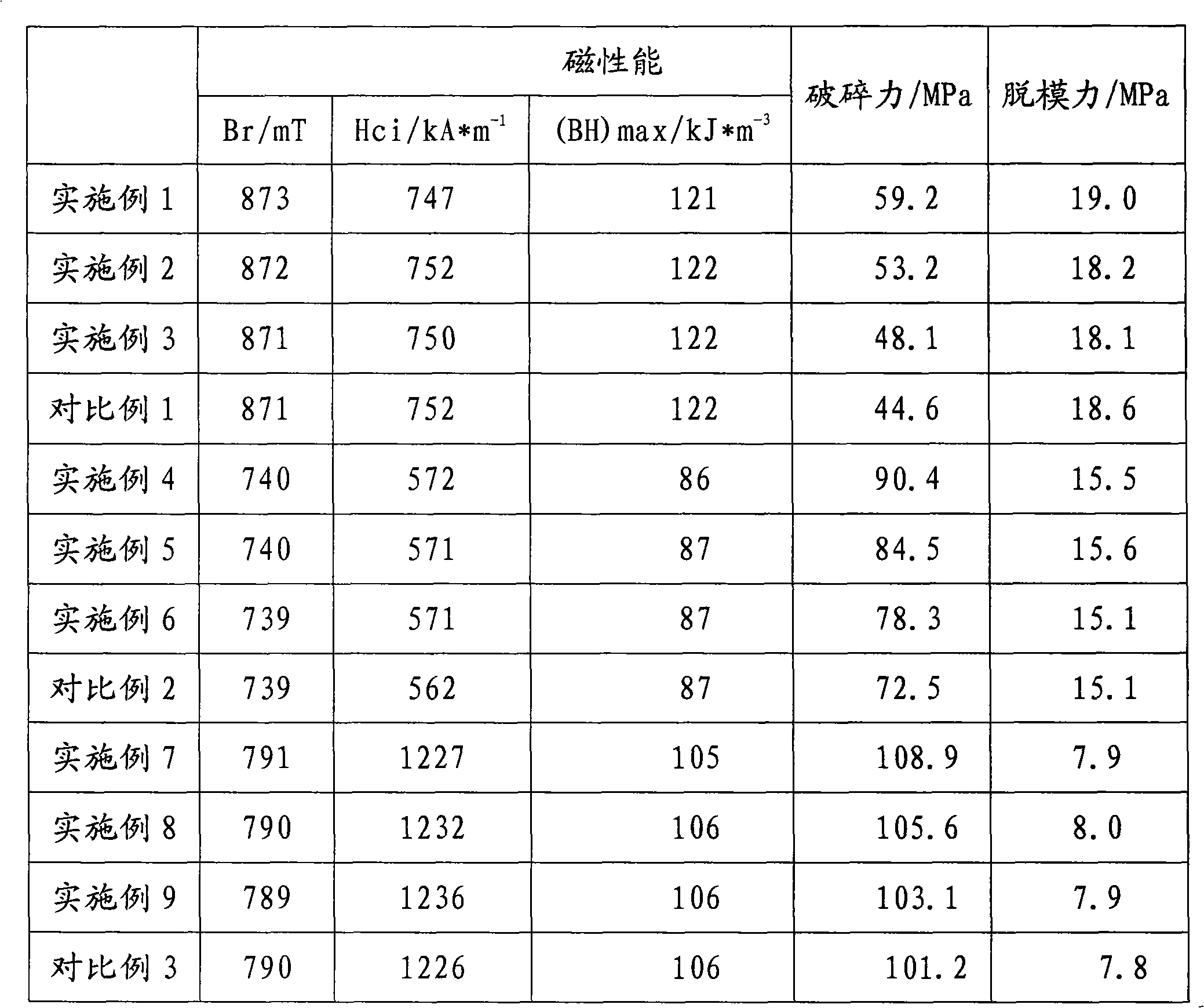

Embodiment 1

[0012] Weigh 10,000g of MQP-B 80mesh magnetic powder, 100g of EPON 840 bisphenol A epoxy resin (epoxy equivalent EEW=330-380), 3.662g of dicyandiamide, 3-(3,3-dichlorophenyl)-1 , 1-dimethylurea 1.831g, Wacker H 20 Silica 20g, acetone 1000g, the above components are prepared into a resin solution, mixed in a planetary mixer for 15 minutes under a nitrogen atmosphere, dried in a blast oven at 55 degrees Celsius for 120 minutes, and the acetone is removed to obtain a magnetic powder containing nano-silica - resin mixture. Utilize the Lakeshore 7312VSM (Vibrating Sample Magnetometer) tester to test the magnetic properties of the obtained magnetic powder-resin mixture; utilize the YA-20 type electro-hydraulic pressure testing machine to investigate the release force of the obtained magnetic powder-resin mixture; utilize Gasbarre 15T press at 14ton / cm 2 Press under pressure to form a ring-shaped magnet green body with an outer diameter of 20.80 mm and an inner diameter of 18.60 m...

Embodiment 2

[0014] Weigh MQP-B 80mesh magnetic powder 10,000g, EPON 840 bisphenol A epoxy resin (EEW=330-380) 100g, dicyandiamide 3.662g, 3-(3,3-dichlorophenyl)-1,1 -Dimethylurea 1.831g, Wacker H 20 Silicon dioxide 10g, tetrahydrofuran 1000g, the above components are prepared into a resin solution, mixed with a planetary mixer for 15 minutes under a nitrogen environment, and dried at 65 degrees Celsius for 120 minutes in a blast oven to remove tetrahydrofuran to obtain nano-silica reinforced Magnetic powder-resin mixture. Utilize the Lakeshore7312VSM (Vibrating Sample Magnetometer) tester to test the magnetic properties of the obtained magnetic powder-resin mixture; utilize the YA-20 type electro-hydraulic pressure testing machine to investigate the release force of the obtained magnetic powder-resin mixture; utilize Gasbarre 15T press at 14ton / cm 2 Press under pressure to form a ring-shaped magnet green body with an outer diameter of 20.80 mm and an inner diameter of 18.60 mm; cure at a...

Embodiment 3

[0016] Weigh 10,000g of MQP-B 80mesh magnetic powder, 100g of EPON 840 bisphenol A epoxy resin (EEW=330-380), 3.662g of dicyandiamide, 3-(3,3-dichlorophenyl)-1,1- Dimethylurea 1.831g, Wacker H 20 Silica 3g, acetone: tetrahydrofuran = 1: 1wt% mixed solution 1000g, above-mentioned components are prepared resin solution, utilize planetary mixer to mix 15 minutes under nitrogen environment, utilize blast oven to dry 120 minutes under the condition of 60 degrees centigrade, remove Solvent to obtain nano-silica reinforced magnetic powder-resin mixture. Utilize the Lakeshore 7312VSM (Vibrating Sample Magnetometer) tester to test the magnetic properties of the obtained magnetic powder-resin mixture; utilize the YA-20 type electro-hydraulic pressure testing machine to investigate the release force of the obtained magnetic powder-resin mixture; utilize Gasbarre 15T press at 14ton / cm 2 Press under pressure to form a ring-shaped magnet green body with an outer diameter of 20.80 mm and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com