Preparation of cation surface sizing agent emulsion

A technology of surface sizing agent and cationic etherifying agent, which is applied in the field of preparation of cationic surface sizing agent emulsion, can solve the problems that the surface strength, folding resistance and solvent resistance cannot be taken into account, and the application range of secondary fibers is limited. To achieve the effect of convenient acquisition of raw materials, expanded reuse, and a wide range of types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

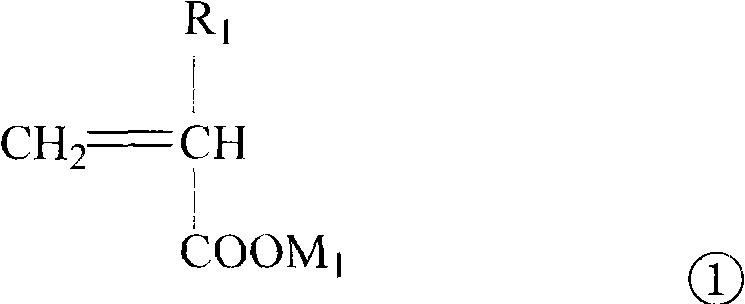

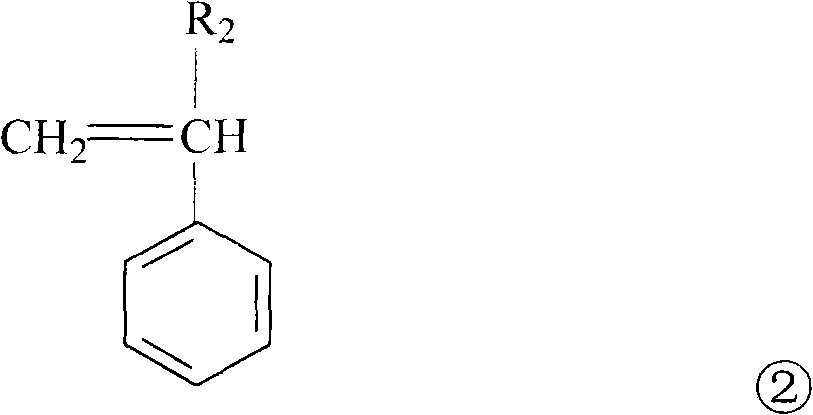

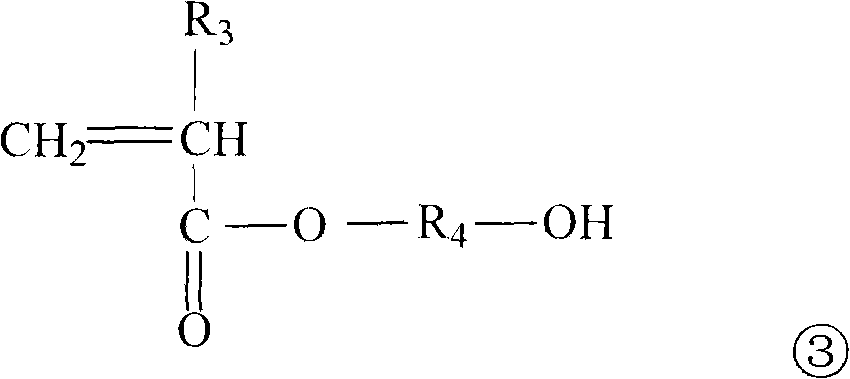

Method used

Image

Examples

Embodiment 1

[0068] Mix polyvinyl alcohol 1099 and water uniformly at a mass ratio of 1:9 to obtain a 10% polyvinyl alcohol solution, that is, polymer colloid stabilizer solution A. 5% of 3-chloro-2-hydroxypropyltrimethylammonium chloride relative to the amount of polyvinyl alcohol was added to the polyvinyl alcohol solution at 80°C. The pH was adjusted to 10 with ammonia and reacted for 1 hour. Adjust its pH to 5 with hydrochloric acid to prepare a modified polyvinyl alcohol solution, namely modified polymer colloid stabilizer B. Mix butyl acrylate, styrene and methylol acrylamide uniformly at a mass ratio of 1:1:0.4 to prepare solution C. Mix water and potassium persulfate uniformly at a mass ratio of 1:0.06 to obtain an aqueous initiator solution D. Mix the modified polyvinyl alcohol solution and water uniformly at a mass ratio of 100:1000 to obtain solution E. At 85°C, add methacryloyloxyethyltrimethylammonium chloride, solution C and initiator aqueous solution D to solution E dropw...

Embodiment 2

[0070] Mix polyvinyl alcohol 1799 and water at a mass ratio of 1:9 to obtain a 10% polyvinyl alcohol solution, that is, polymer colloid stabilizer solution A. Then, at 95° C., 8% of 3-chloro-2-hydroxypropyltrimethylammonium chloride relative to the amount of polyvinyl alcohol was added to the solution polyvinyl alcohol solution. At the same time, the pH was adjusted to 11 with sodium hydroxide, and the reaction was carried out for 1.5 hours. Adjust its pH to 5 with sulfuric acid to prepare a modified polyvinyl alcohol solution, namely modified polymer colloid stabilizer B. Methyl methacrylate, stearyl acrylate, butyl methacrylate and methylol acrylamide were uniformly mixed at a mass ratio of 1:0.1:1:0.5 to prepare solution C. Water and ammonium persulfate-sodium (hydrogensulfite) were uniformly mixed at a mass ratio of 1:0.02 to obtain an aqueous initiator solution D. Mix the solution-modified polyvinyl alcohol solution and water uniformly at a mass ratio of 100:800 to obta...

Embodiment 3

[0072] Mix polyvinyl alcohol 0588 and water uniformly at a mass ratio of 1:9 to obtain a polyvinyl alcohol solution, that is, polymer colloid stabilizer solution A. At 90°C, 10% cationic etherifying agent 2,3-epoxypropyltrimethylammonium chloride relative to the amount of polyvinyl alcohol was added to the polyvinyl alcohol solution. At the same time, the pH was adjusted to 11 with potassium hydroxide and reacted for 1 hour. Adjust its pH to 6 with nitric acid to prepare a modified polyvinyl alcohol solution, namely modified polymer colloid stabilizer B. Solution C was prepared by uniformly mixing butyl methacrylate, styrene, and acetoacetoxy ethyl methacrylate at a mass ratio of 0.8:1:0.5. Water and ammonium persulfate were uniformly mixed at a mass ratio of 1:0.06 to obtain an aqueous initiator solution D. Mix the modified polyvinyl alcohol solution and water uniformly at a mass ratio of 100:900 to obtain solution E. Then, at 85°C, dimethylaminoethyl methacrylate, benzyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com