Process for preparing niobium-doped strontium titanate film

A technology of doping strontium niobate titanate thin film, which is applied in the field of preparation of strontium niobium titanate thin film, can solve the problems of harsh preparation environment, high cost, inconvenient operation, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

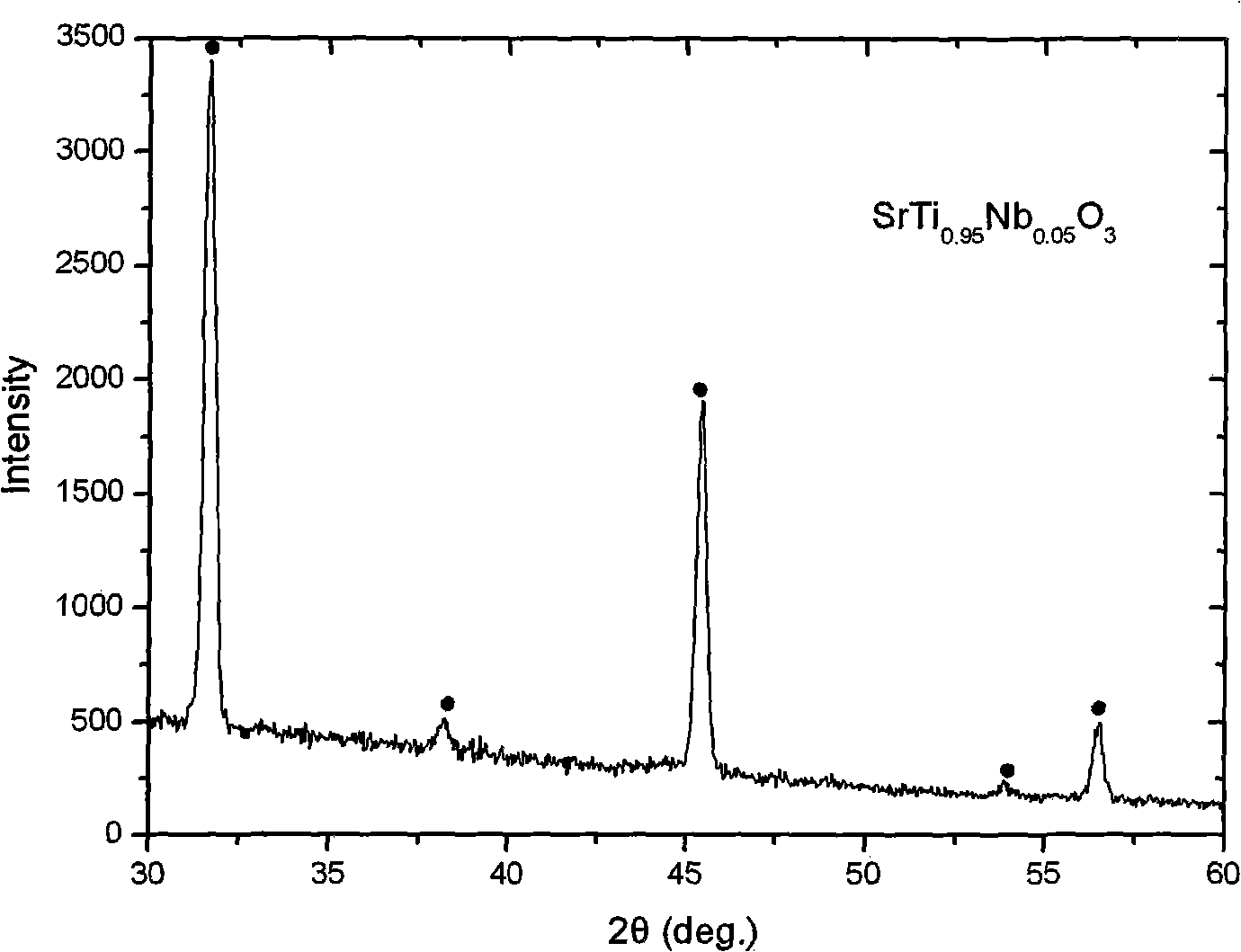

[0019] A specific embodiment of the present invention is a method for preparing a strontium niobate-doped titanate thin film, the specific steps of which are:

[0020] a. Preparation of niobium-citrate ethylene glycol solution: place niobium oxide in hydrofluoric acid, stir at 80°C to make it fully dissolve to form a niobium oxide solution, add ammonia water dropwise to the solution to form a white niobium hydroxide precipitate, Aging for 4 hours; after filtration, the precipitate was washed with 3% dilute ammonia water, dehydrated and dried in a vacuum; the dried precipitate was dissolved in citric acid in ethylene glycol solution at 60°C and fully stirred to obtain Niobium-citrate solution in ethylene glycol.

[0021] b. Preparation of strontium niobate titanate precursor solution: molar ratio of Sr 2+ : Ti 4+ : Nb 5+ =1: 0.95: 0.05, respectively measure strontium acetate, butyl titanate and the niobium-citrate ethylene glycol solution prepared in step a; dissolve stronti...

Embodiment 2

[0025] a, niobium-citric acid ethylene glycol solution preparation: niobium oxide Nb 2 o 5 Add it into hydrofluoric acid HF, heat in a water bath at 85°C for 6 hours, and keep stirring, so that the Nb 2 o 5 Fully dissolve. Slowly add ammonia water dropwise to the solution to form white Nb(OH) 5 Precipitate, which was aged at 80°C for 6 hours and then filtered, washed repeatedly with 2% dilute ammonia to remove F - ions, dehydrated and dried in vacuum for 2 minutes. The resulting white precipitate was dissolved in citric acid in ethylene glycol solution at 80° C., and stirred thoroughly to form Nb-citric acid in ethylene glycol solution.

[0026] b. Preparation of strontium niobate titanate precursor solution: molar ratio of Sr 2+ : Ti 4+ : Nb 5+ =1: 0.995: 0.005, respectively measure strontium acetate, butyl titanate and the niobium-citrate ethylene glycol solution prepared in step a; dissolve strontium acetate in acetic acid to form solution A; The molar amount of dr...

Embodiment 3

[0029] a. Preparation of niobium-citrate ethylene glycol solution: place niobium oxide in hydrofluoric acid, stir at 70°C to fully dissolve to form a niobium oxide solution, add ammonia water dropwise to the solution to form a white niobium hydroxide precipitate, Aging for 5 hours; after filtration, the precipitate was washed with 4% dilute ammonia water, dehydrated and dried in vacuum; the dried precipitate was dissolved in citric acid in ethylene glycol solution at 70°C and fully stirred to obtain Niobium-citrate solution in ethylene glycol.

[0030] b. Preparation of strontium niobate titanate precursor solution: molar ratio of Sr 2+ : Ti 4+ : Nb 5+ =1: 0.95: 0.05, respectively measure strontium acetate, butyl titanate and the niobium-citrate ethylene glycol solution prepared in step a; dissolve strontium acetate in acetic acid to form solution A; The molar amount of dropwise addition is Ti 4+ 1.3 times of acetylacetone, then add ethylene glycol methyl ether solvent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com