Stable medicine combination

A composition and drug technology, applied in the field of stable pharmaceutical compositions, can solve the problems of pharmaceutical compositions failing to meet the storage period requirements, restrictions on large-scale popularization and use, and difficult operation of formulated products, so as to achieve fast and rapid onset of effect Thoroughly absorbed, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

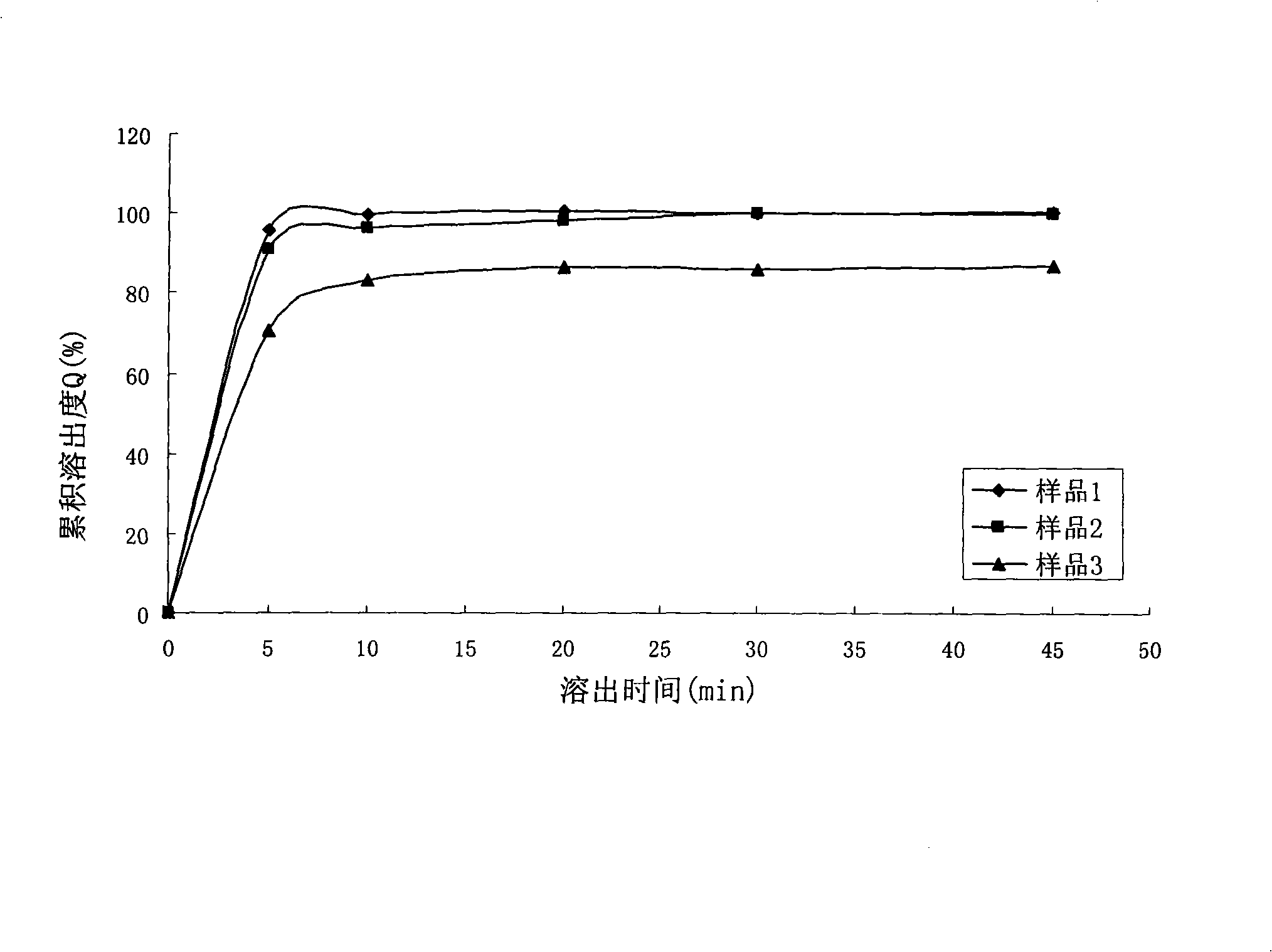

Embodiment 1

[0028] Raw material name 1000 tablets dosage (g)

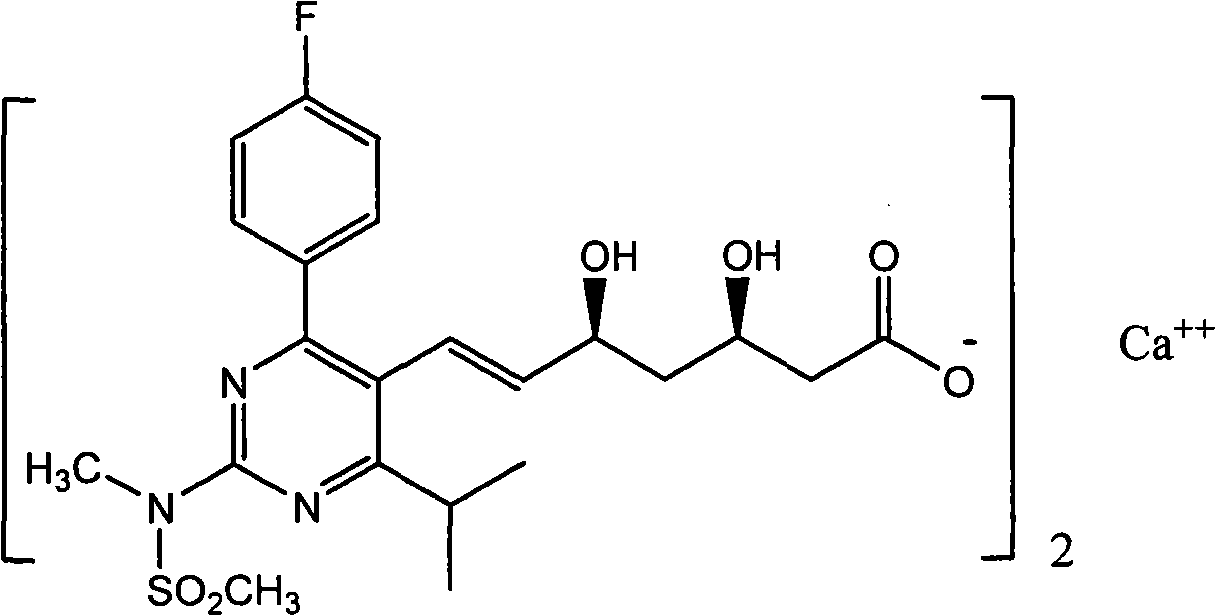

[0029] Rosuvastatin calcium 10.4 (equivalent to rosuvastatin 10g)

[0030] Micronized silica gel 6

[0031] Microcrystalline Cellulose 80

[0032] Lactose 95

[0033] Crospovidone (internal addition) 8

[0034] Crospovidone (additional) 8

[0035] Povidone K 30 5

[0036] Appropriate amount of water

[0038] Gastric-soluble film coating premix appropriate amount

[0039] Pass rosuvastatin calcium and micro-powder silica gel through a 100-mesh sieve and mix evenly, add the prescribed amount of microcrystalline cellulose, lactose, crospovidone (internal addition), and povidone through a 80-mesh sieve, and mix well . Add an appropriate amount of water-based soft material to the powder, pass through a 20-mesh sieve to granulate, blow dry at 45°C, pass the dry granules through a 20-mesh sieve for granulation, add the prescribed amount of crospovidone (additional), mix properly an...

Embodiment 2

[0041] Raw material name 1000 tablets dosage (g)

[0042] Rosuvastatin calcium 5.2 (equivalent to rosuvastatin 5g)

[0043] Micronized silica gel 5

[0044] Pregelatinized starch 60

[0045] Mannitol 75

[0046] Low-substituted hydroxypropyl cellulose 5

[0047] 3% hypromellose (E 5 ) aqueous solution appropriate amount

[0049] Gastric-soluble film coating premix appropriate amount

[0050] Pass rosuvastatin calcium and micropowder silica gel through a 100-mesh sieve and mix evenly, add pregelatinized starch, mannitol, and low-substituted hydroxypropyl cellulose in the prescribed amount and pass through an 80-mesh sieve, and mix well. Add an appropriate amount of 3% hydroxypropyl methylcellulose aqueous solution to the powder to make a soft material, pass through a 20-mesh sieve to granulate, dry at 45°C, dry the dry granules through a 20-mesh sieve, add the prescribed amount of magnesium stearate, well mixed. After detecting the interme...

Embodiment 3

[0052] Raw material name 1000 tablets dosage (g)

[0053] Rosuvastatin calcium 20.8 (equivalent to rosuvastatin 20g)

[0054] Micronized silica gel 10

[0055] Microcrystalline Cellulose 60

[0056] Cross-linked hydroxypropyl methylcellulose 9

[0057] Appropriate amount of water

[0058] Stearic acid 0.8

[0059] Gastric-soluble film coating premix appropriate amount

[0060] Pass rosuvastatin calcium and micropowder silica gel through a 100-mesh sieve and mix evenly, add the prescribed amount of microcrystalline cellulose and cross-linked hydroxypropyl methylcellulose that pass through an 80-mesh sieve, and mix well. Add an appropriate amount of water-based soft material to the powder, pass through a 24-mesh sieve to granulate, blow dry at 45°C, pass the dry granules through a 24-mesh sieve for granulation, add the prescribed amount of stearic acid passed through a 80-mesh sieve, and mix well. After detecting the intermediate content and water content, the tablet is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com