Hollow microsphere containing silicon magnetism and preparation method and use thereof

A magnetic and hollow technology, used in the preparation of microspheres, magnetic materials, magnetic objects, etc., can solve the problems of inability to form a stable dispersion system, high density, easy aggregation and precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take 0.07mol FeCl respectively 3 ·6H 2 O and 0.04mol FeSO 4 ·7H 2 O is added with water to form a 0.5mol / L solution, mixed evenly, poured into a four-necked flask and stirred under nitrogen protection, and then 24ml of NH 3 ·H 2 O, aged at 90°C for 30min after the dropwise addition. After the reaction is over, use a strong magnet to hold the bottom of the flask until the magnetic Fe in the system 3 o 4 After sinking, pour off the upper waste liquid, wash repeatedly with deionized water, make the pH of the solution=7, add an appropriate volume of water to adjust Fe 3 o 4 The solid content is up to 6%.

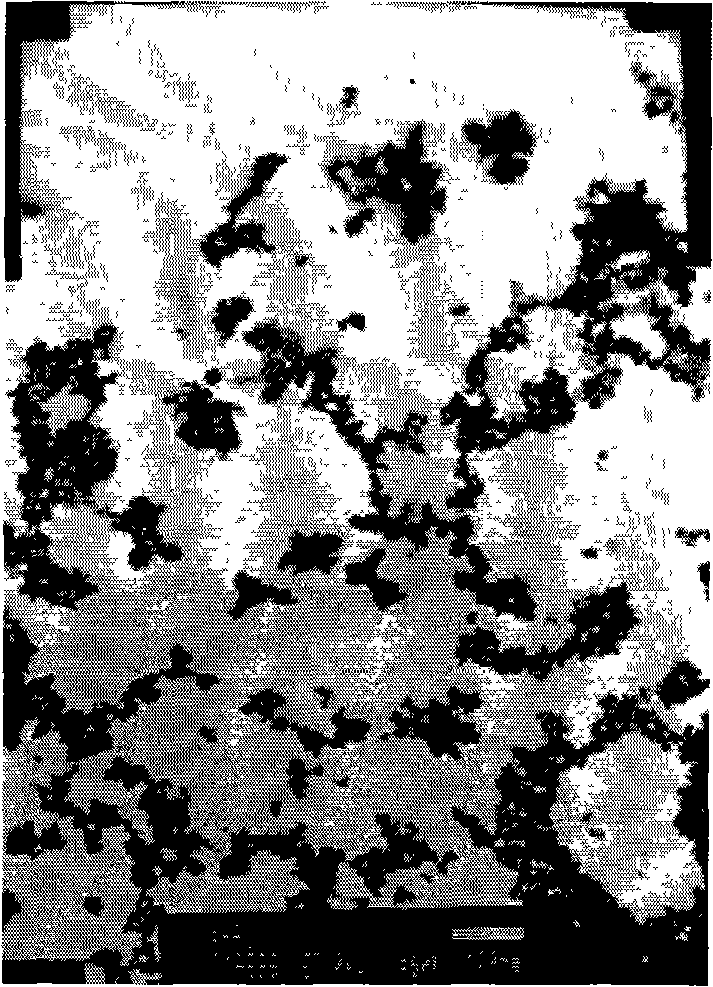

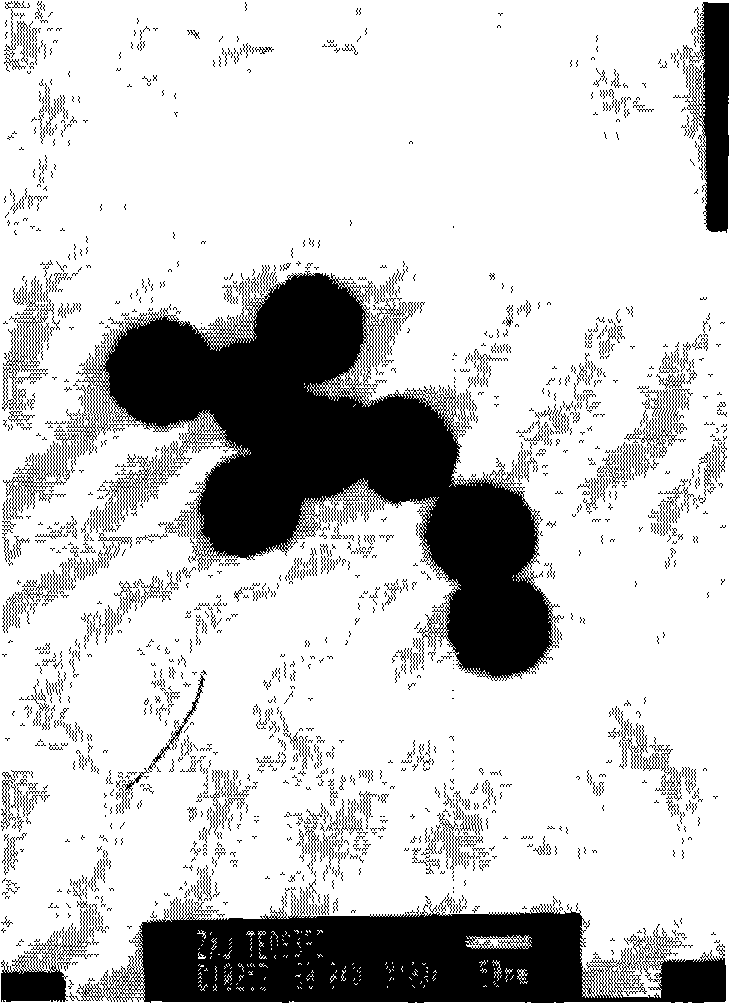

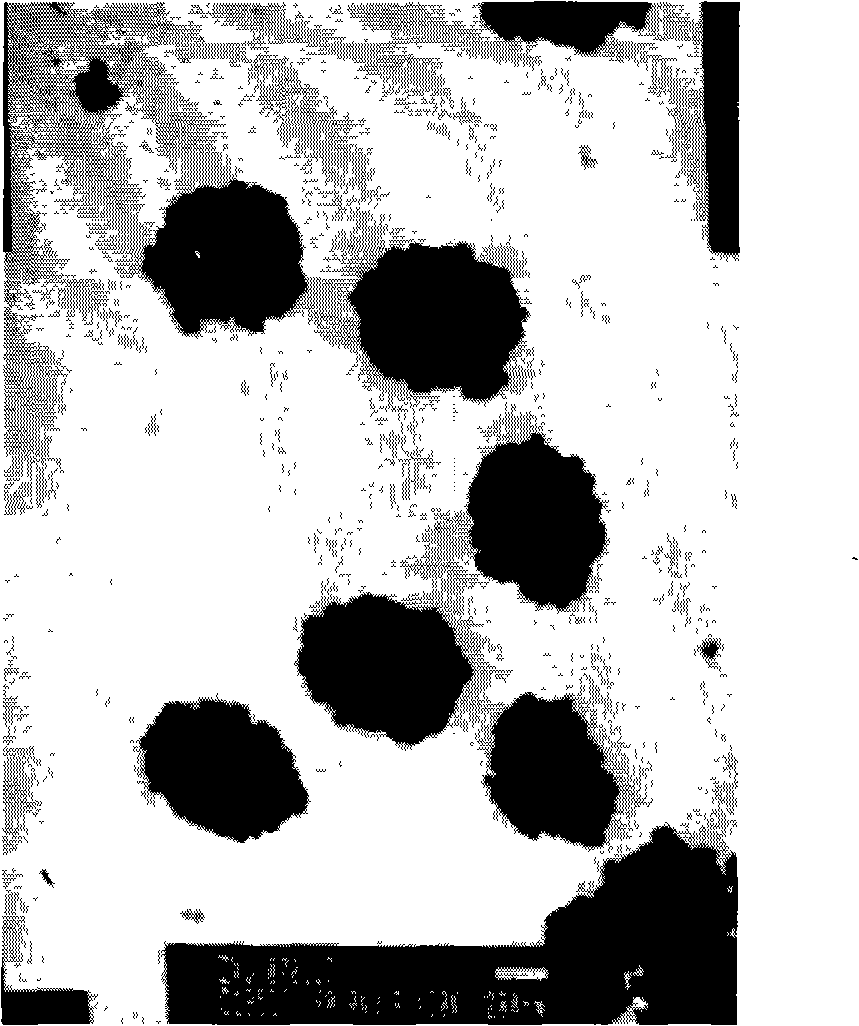

[0039] Fe 3 o4 The morphology of the particles was observed, and the results were as follows figure 1 shown.

[0040] Add 0.4g APS, 0.1g SDS and 120ml double-distilled water into a four-neck flask equipped with mechanical stirring, reflux condenser, and nitrogen protection, stir for 10min, then add 20ml St, nitrogen protection, heat to 70°C for one hour, slowly...

Embodiment 2

[0049] Add 0.4gAPS and 0.8gNH 4 HCO 3 and 120ml of double-distilled water, stirred for 10min, then added 20ml of St, nitrogen protection, heated to 70°C for one hour, slowly added 4g of silane coupling agent KH-570, continued to react for 9 hours, cooled and stood still after the reaction was completed, and obtained White lotion, ready to use.

[0050] Take 1.8g of the above-mentioned white emulsion to the Erlenmeyer flask, add 50ml of absolute ethanol, 7ml of water and 0.7g of PVP, add 1ml of ammonia water after ultrasonication for 30min, stir magnetically, slowly add TEOS, continue stirring for 3 hours after the dropwise addition, and obtain PS / SiO 2 Organic-inorganic composite microspheres (MPSi).

[0051] Place the above MPSi microspheres in a centrifuge (V=3000rpm) for centrifugation, pour off the upper liquid, add double distilled water and continue centrifuging, repeat this operation 4 times, wash the sample to remove excess polystyrene, ammonia water, etc. Dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com