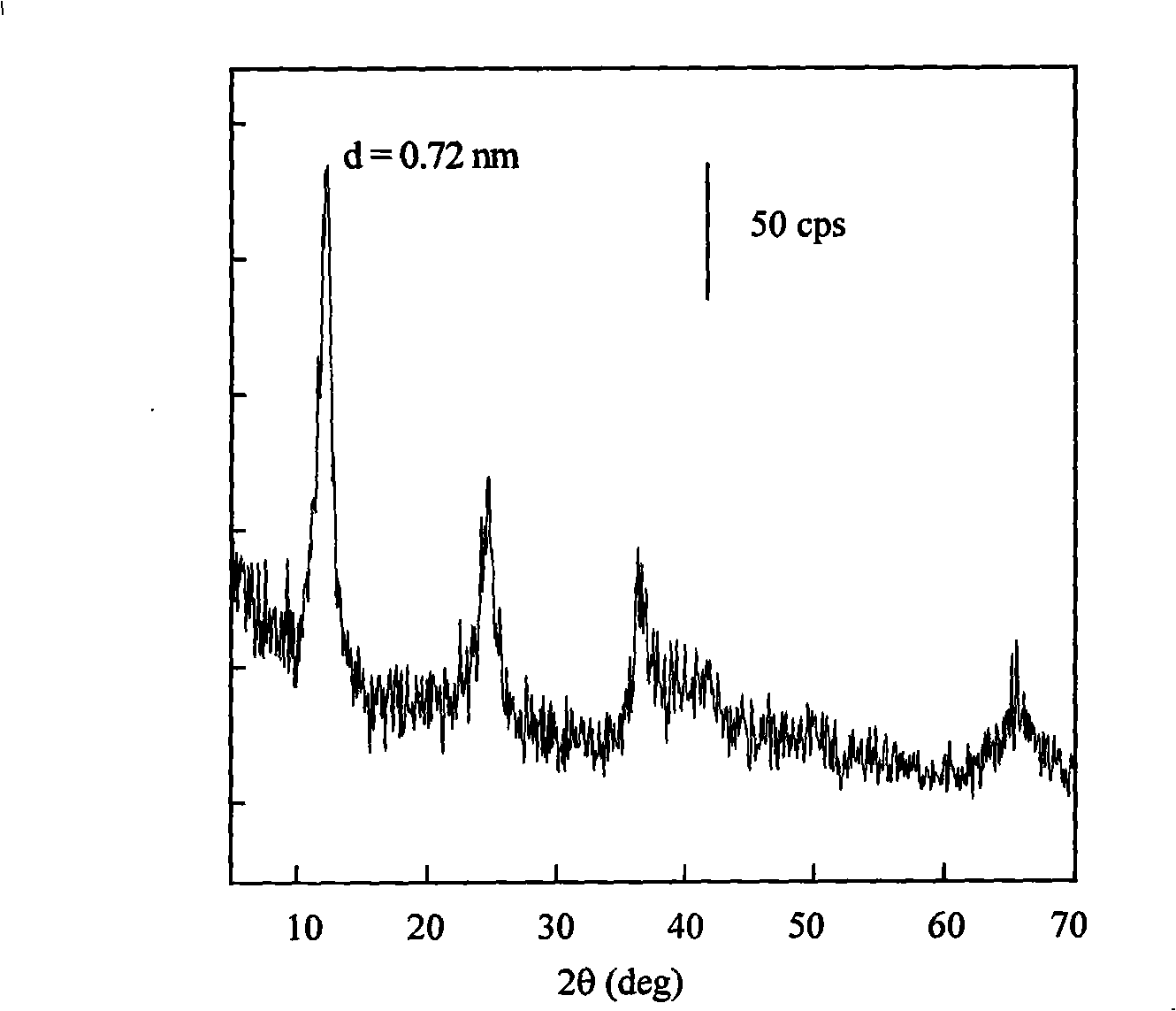

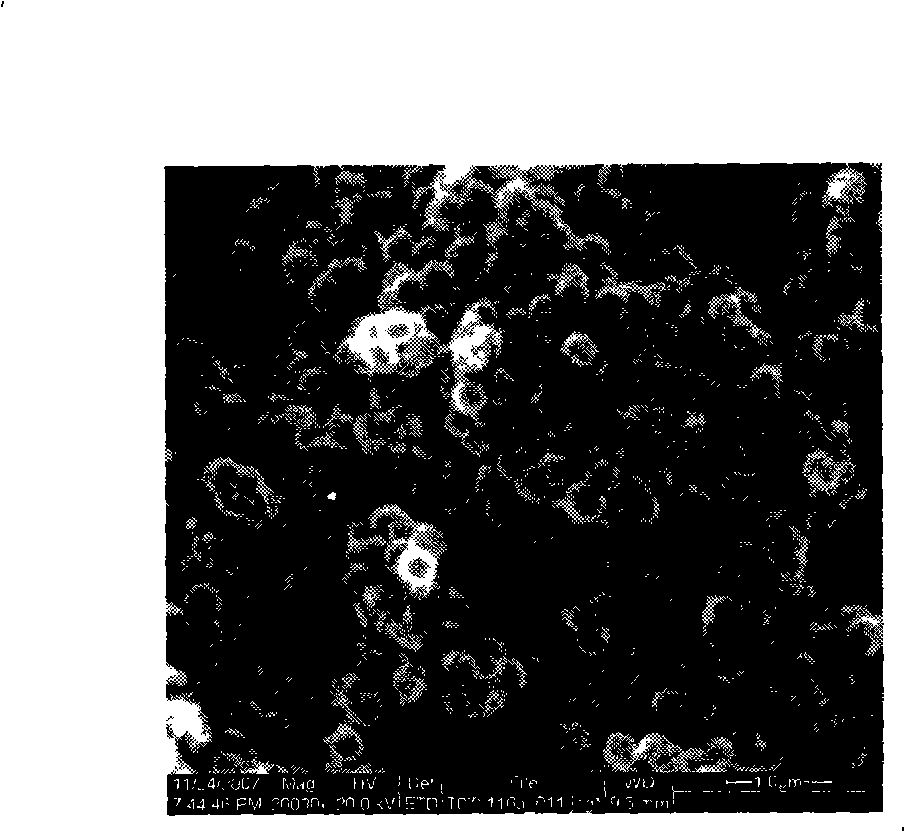

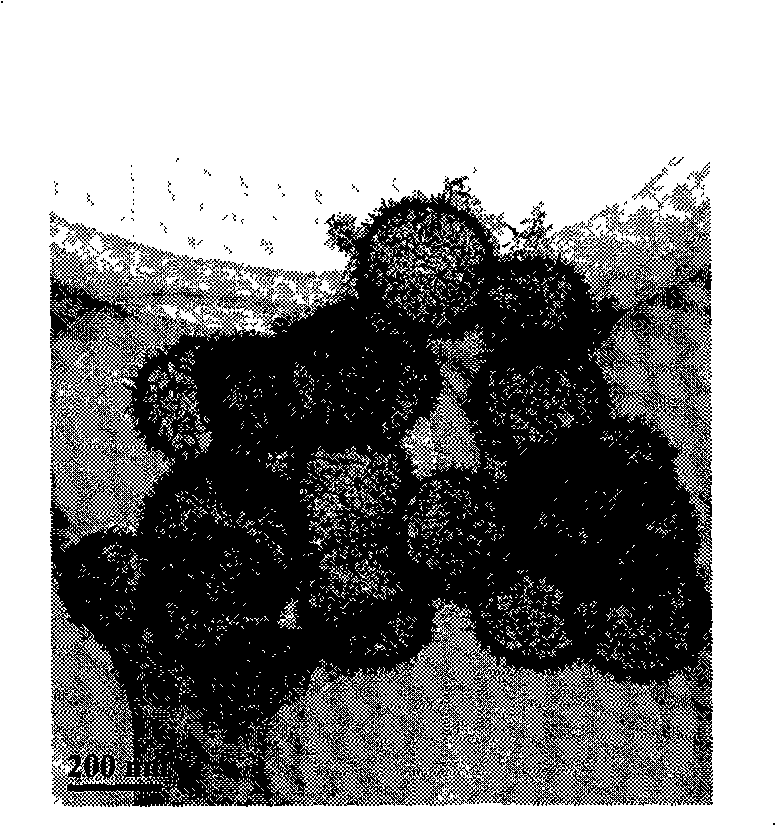

Method of preparing manganese oxide hollow nano-sphere with large-specific surface area

A large specific surface area, hollow nano technology, applied in the field of materials, can solve the problems of limiting the application of preparation materials and small specific surface area, and achieve the effects of low production cost, large specific surface area and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of silica nanospheres

[0035] Mix 6.0mL of ammonia water with a mass concentration of 30% and 50.0mL of absolute ethanol, control the temperature at 40°C, use a power of 240W and ultrasonic generator frequency of 40KHz for 10 minutes, and then dissolve 3.0mL of tetraethylsilane in 8 Add drops / min to the above mixed solution. The volume ratio of tetraethylsilane to ammonia water and ethanol with a mass concentration of 30% is 1:2:17. Ultrasonic treatment for 10 minutes, centrifugation at 8000 rpm for 10 minutes, the precipitate was washed with deionized water until the pH of the supernatant was 8-9, and prepared into silica nanospheres.

[0036] 2. Preparation of manganese oxide-coated silica composite nanospheres

[0037] Disperse 0.83 g of silica nanospheres in 12 mL of potassium permanganate solution with a concentration of 0.38 mol / L, the molar ratio of potassium permanganate to silica nanospheres is 1:3, and generate ultrasonic waves with a power of...

Embodiment 2

[0042]In the process step 2 of preparing manganese oxide-coated silica composite nanospheres in Example 1, 1.05 g of silica nanospheres were dispersed in 12 mL of potassium permanganate solution with a concentration of 0.38 mol / L, so that the permanganese The molar ratio of potassium phosphate and silicon dioxide nanospheres is 1:3.8, and the ultrasonic wave with a power of 240W is used for 30 minutes at a generator frequency of 40KHz, and the resulting suspension is placed in a pressure container, and the pressure container is In a homogeneous reactor, hydrothermal reaction was carried out at 130° C. for 48 hours, and the other steps of this process were the same as in Example 1. In step 3 of the process for preparing manganese oxide hollow nanospheres, 0.5 g of manganese oxide-coated silica composite nanospheres is mixed with 62.5 g of aqueous sodium hydroxide solution with a mass concentration of 20%, and the manganese oxide-coated silica composite The mass ratio of nanosph...

Embodiment 3

[0044] In the process step 2 of preparing manganese oxide-coated silica composite nanospheres in Example 1, 1.24 g of silica nanospheres were dispersed in 12 mL of potassium permanganate solution with a concentration of 0.38 mol / L, and the permanganate The molar ratio of potassium to silicon dioxide nanospheres is 1: 4.5, and with an ultrasonic generator with a power of 240W, after ultrasonic treatment at a frequency of 40KHz for 30 minutes, the resulting suspension is placed in a pressure bomb, and the pressure bomb is placed in In a homogeneous reactor, hydrothermal reaction was carried out at 200° C. for 48 hours. The other steps of this process step were the same as in Example 1. In step 3 of the process for preparing manganese oxide hollow nanospheres, 0.5 g of manganese oxide-coated silica composite nanospheres is mixed with 125 g of sodium hydroxide aqueous solution with a mass concentration of 20%, and the manganese oxide-coated silica composite nanospheres Ball and ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com