Quasi solid electrolyte for dye sensitization solar battery and preparation method thereof

A technology of solar cells and dye sensitization, which is applied in the quasi-solid electrolyte of dye-sensitized solar cells and its preparation field, which can solve the problems of photoelectric conversion efficiency and stability limitation, sealing process not improved, hole transport rate is not high, etc. , to achieve the effect of being beneficial to collection, improving energy conversion efficiency and improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

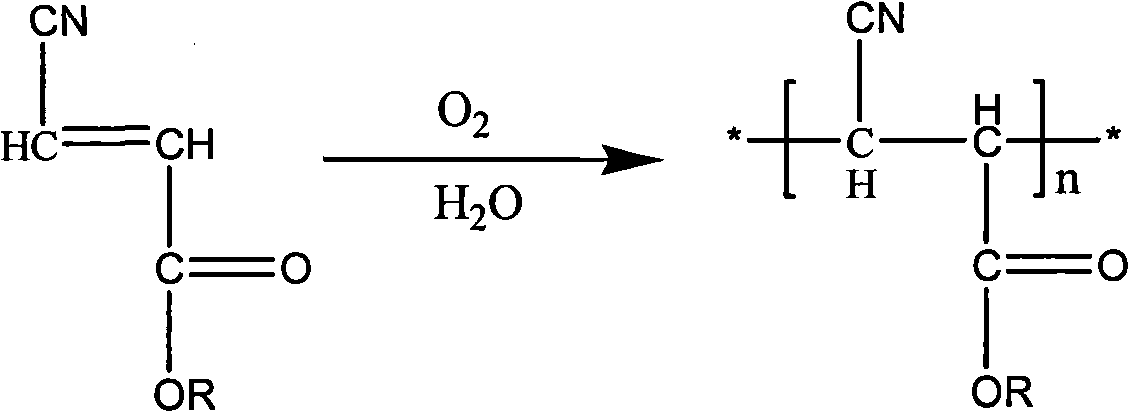

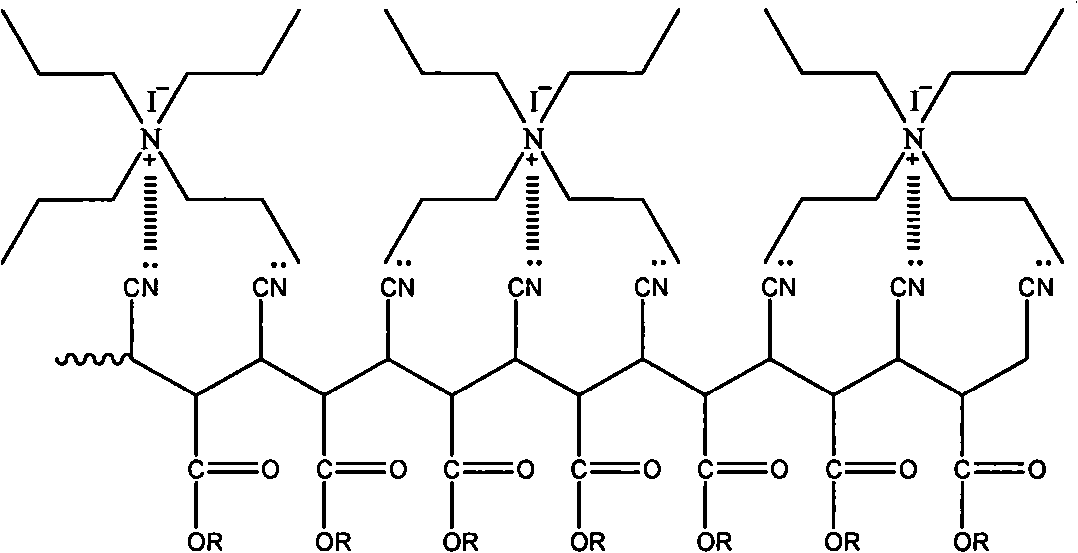

Method used

Image

Examples

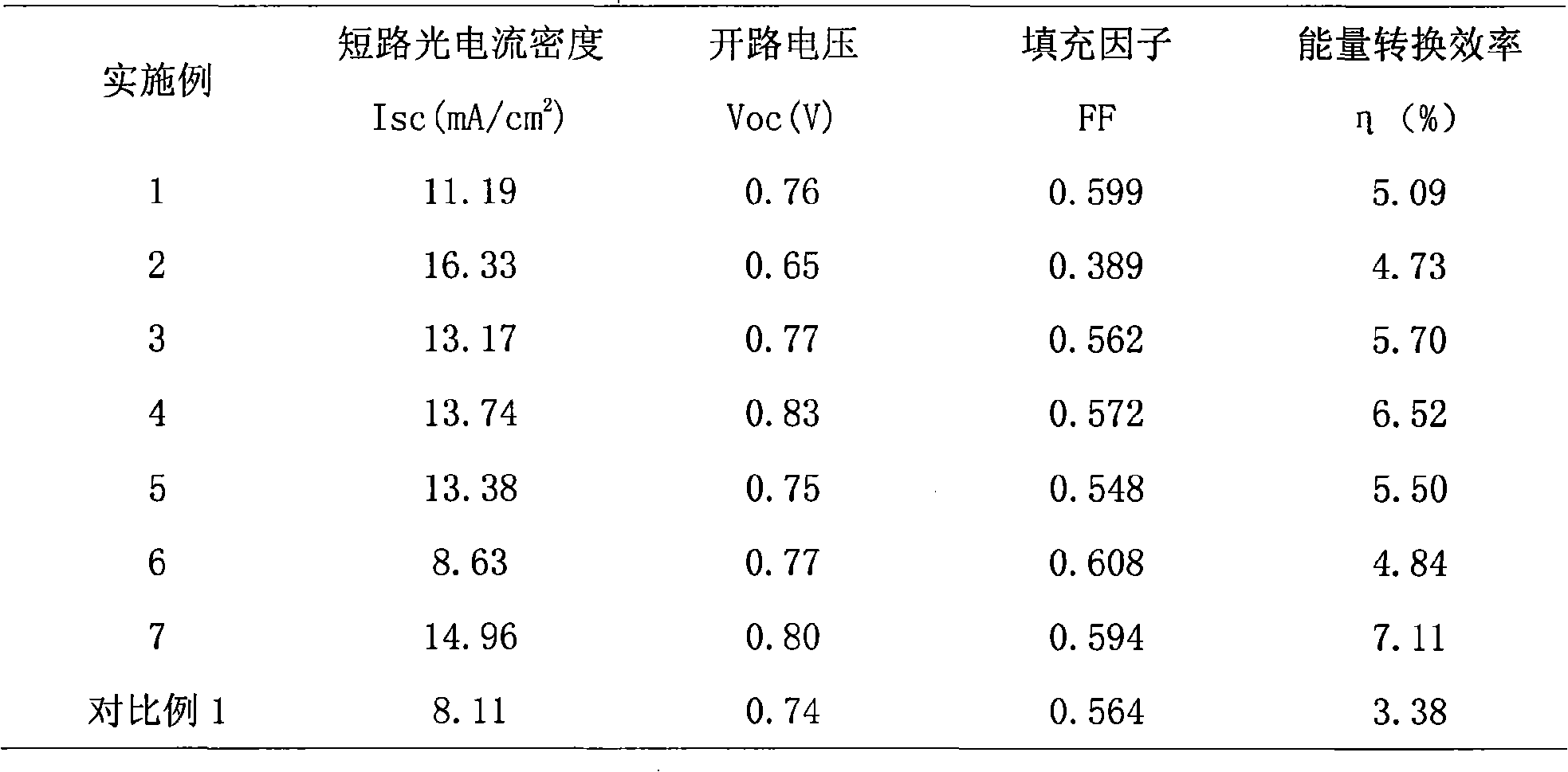

Embodiment 1

[0023] The quasi-solid electrolyte is composed of the following components and weight ratio: 5% ethyl α-cyanoacrylate; 0.2% polyethylene glycol diacrylate with a molecular weight of 200; 12% tetrapropylammonium iodide; 1.5% iodine; 5% tert-butylpyridine; 56.3% ethylene carbonate; 20% acetonitrile.

Embodiment 2

[0025] The quasi-solid electrolyte is composed of the following components and weight ratio: 5% ethyl α-cyanoacrylate; 0.1% polyethylene glycol diacrylate with a molecular weight of 200; 20% 1-propyl-3-methylimidazolium iodine 3% iodine; 1% tert-butylpyridine; 60% ethylene carbonate; 10.9% acetonitrile.

Embodiment 3

[0027] The quasi-solid electrolyte is composed of the following components and weight ratio: 10% propyl cyanoacrylate; 0.5% polyethylene glycol diacrylate with a molecular weight of 200; 10% tetrapropylammonium iodide, lithium iodide 1 %; iodine 1%; tert-butylpyridine 5%, guanidine isothiocyanate 1%; propylene carbonate 52.5%; acetonitrile 10%; methoxypropionitrile 9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com