Heat resistant bovine colostrum immunoglobulin and preparation method

An immunoglobulin and heat-resistant technology, which is applied in the fields of milk immunoglobulin, preparation method of peptide, protein composition of milk, etc., can solve the problem of no heat-resistant bovine colostrum immunoglobulin reported, etc. Achieving the effect of low cost, reduced energy consumption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 heat-resistant bovine colostrum immunoglobulin

[0028] Follow the steps below:

[0029] (1) Collect 100kg of bovine colostrum on the first day, centrifuge at 4000g for 9min, take the supernatant, then heat-treat and sterilize at 72°C for 15s, then adjust the pH of the system to 4.4 with 1N HCl and keep it for 35min, then Centrifuge for 8 minutes, remove the precipitated casein, and obtain 93kg of supernatant;

[0030] (2) Ultrafiltration of the ultrafiltration device (produced by Beijing Xucheng Ultrafiltration Equipment Factory) with a membrane aperture of 100kD through the gained supernatant for 3 times to obtain a whey concentrate is 35kg; in the whey concentrate, add 1.5g of Thermal denaturation protection agent (composition and weight percentage of thermal denaturation protection agent are: fructo-oligosaccharide 42%, sorbitol 8%, malt-oligosaccharide 40% and glycine 10%), and keep warm at 70 ℃ for 20s;

[0031] (3) The whey conce...

Embodiment 2

[0032] The preparation of embodiment 2 thermostable bovine colostrum immunoglobulin

[0033] Follow the steps below:

[0034] (1) Collect 200kg of bovine colostrum on the second day, centrifuge at 4000g for 9min to remove fat deposits, heat-treat and sterilize the resulting supernatant at 75°C for 12s, then use 1N HCl to adjust the pH of the system to 4.5 and keep it for 40min. Centrifuge for 9 minutes, remove the precipitated casein, and obtain 188kg of supernatant;

[0035] (2) the supernatant is ultrafiltered 3 times through a device with a membrane aperture of 100kD, after ultrafiltration, 68kg of whey concentrate is obtained; 2.8g of heat denaturation protective agent (heat denaturation protection agent) is added in the whey concentrate The composition and its weight percentage are: fructo-oligosaccharide 40%, sorbitol 10%, malt-oligosaccharide 42% and glycine 8%), at 72 ℃ for 18s;

[0036] (3) Spray-dry the whey concentrate at low temperature (inlet air temperature is ...

Embodiment 3

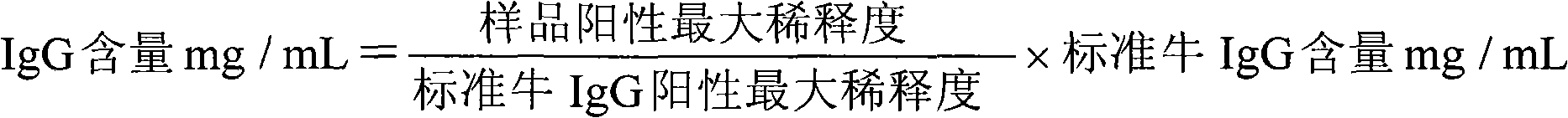

[0037] The mensuration of embodiment 3 immunoglobulin content of the present invention

[0038] (1) Plate preparation: take 0.1g of agarose, add 10ml of PBS solution, heat it in an electric furnace until it boils to dissolve fully, and pour the solution into a horizontal plate after it is cooled to about 50°C, solidify and completely cool, then place it upside down for 4 ℃ refrigerator for 30 minutes.

[0039] (2) Punching: With the center of the plate as the center, use a puncher to punch 6 holes along the periphery and 1 hole in the center. Use a needle to pick out the agar in the well.

[0040] (3) Standard bovine IgG labeling: add 8ul of rabbit anti-bovine IgG at a certain dilution to the central well, and add 8ul of standard bovine IgG at a certain dilution to the peripheral wells.

[0041] (4) Cultivation: After adding the sample, after standing still for a few minutes, place it upside down in a wet box, and place it horizontally in a 37°C incubator.

[0042] (5) Obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com