Novel fermentation tank

A fermenter, a new type of technology, applied in the field of enzymology or microbiology devices, can solve the problems of short service life, low mechanical strength, unsuitable for biological fermentation, etc., to reduce material and energy consumption, simplify production process, improve equipment The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

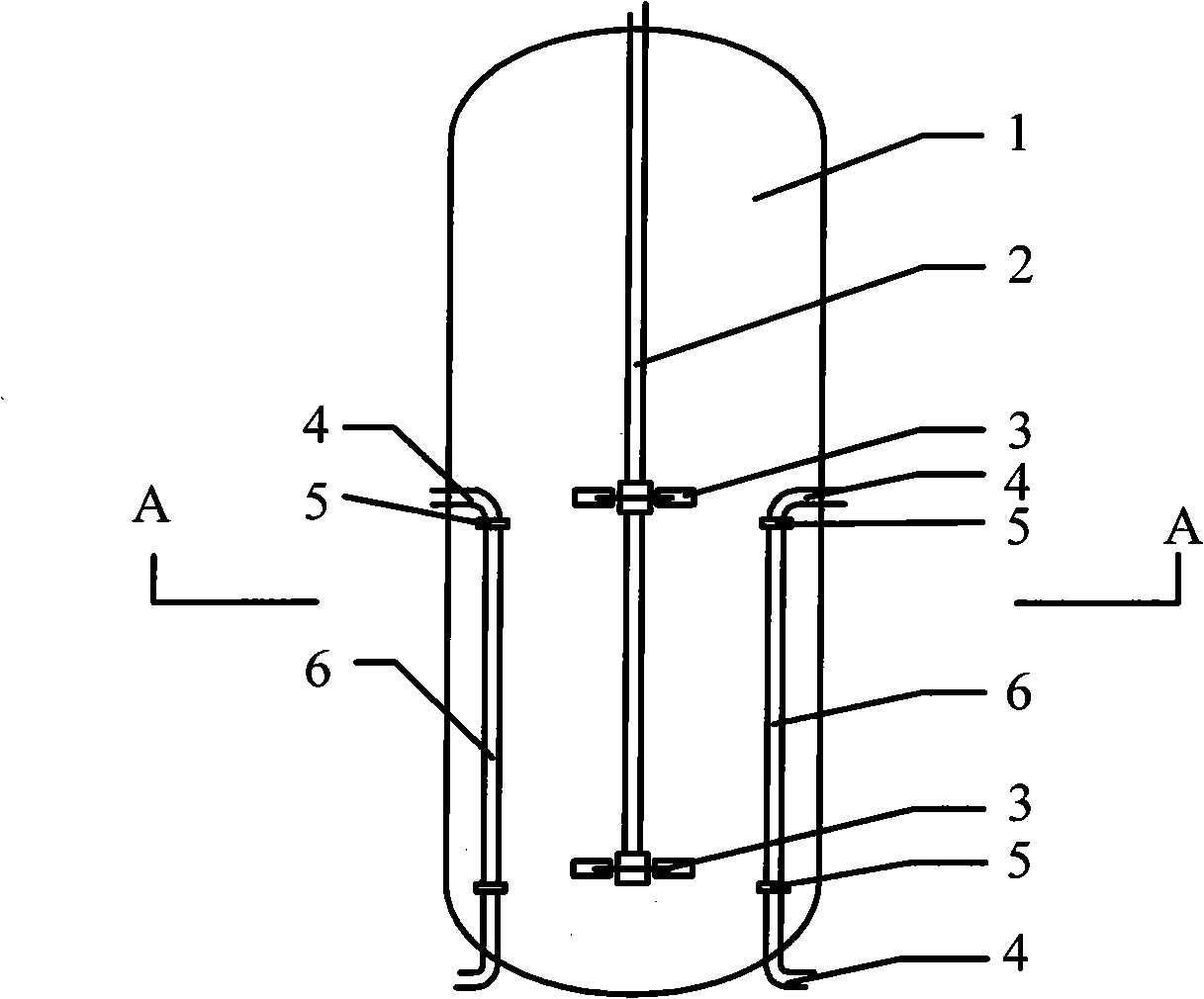

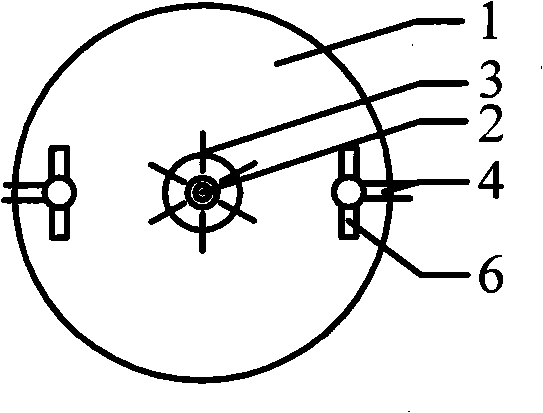

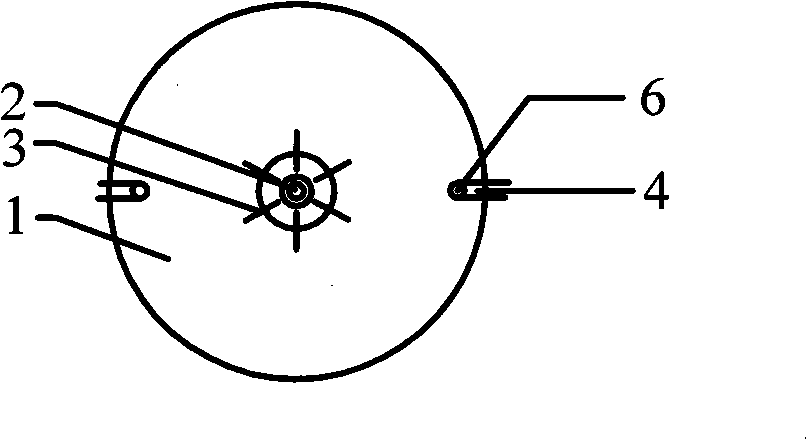

[0029] Such as figure 1 As shown, the integrated novel fermentation tank includes a tank body 1, a membrane filter 6, and a pipeline 4 connected to the membrane filter. The membrane filter 6 is placed inside the tank body 1 and connected by one end of the pipeline 4, and the pipeline 4 The other end passes through the tank body 1 wall. The membrane filter 6 can be parallel to the longitudinal axis of the tank body 1, and the number can be two symmetrically arranged in the tank, and the membrane can be a plate membrane, such as figure 2 As shown, it can also be a tubular membrane, and the cross-sectional view is shown in image 3 shown. Membrane filter 6 can also be installed on tank body 1 wall vertically with fermentation tank longitudinal axis, as Figure 4 As shown, the periphery of the membrane filter 6 is provided with a supporting and fixing fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com