Method for implementing gallium nitride thin film low temperature deposition on silicon substrate

A technology of silicon substrate and gallium nitride, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of limiting the application and promotion of gallium nitride materials, lattice mismatch, poor heat dissipation performance, etc., and achieve the problem of thermal expansion coefficient mismatch Matching problems, improving application level, and good practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

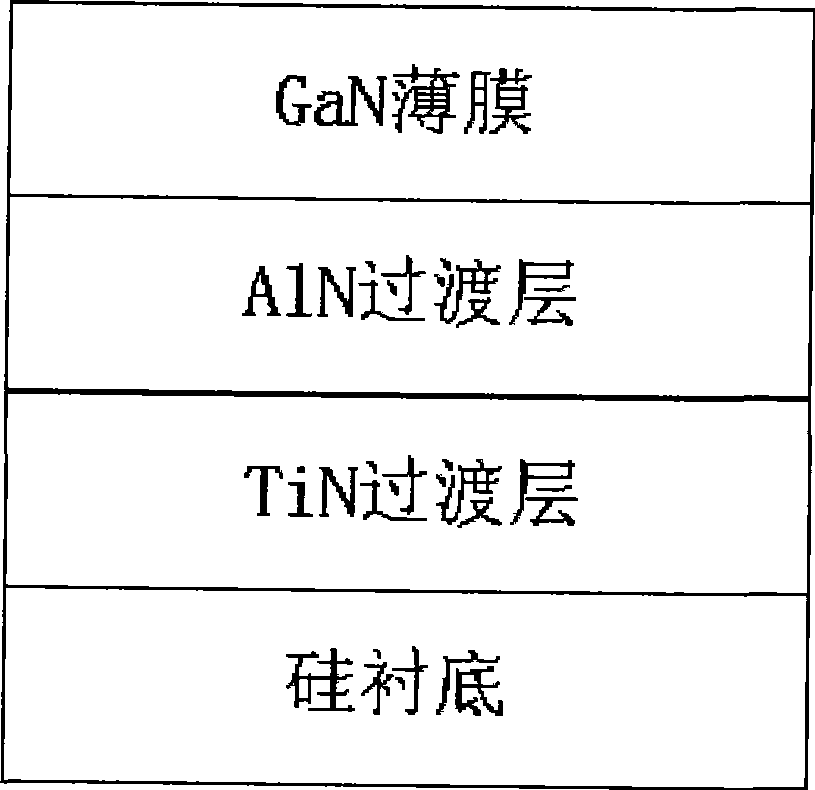

[0027] In the preparation of blue light-emitting materials such as gallium nitride, metal-organic chemical vapor deposition (MOCVD) and molecular beam epitaxy (MBE) are widely used at home and abroad to deposit on sapphire and silicon carbide substrates. The purpose of the present invention is to improve this and promote the industrialization of gallium nitride thin film materials. The specific method is as follows:

[0028] 1) Using the Langmuir probe to diagnose the spatial distribution of the ECR plasma

[0029] 2) Use a grating monochromator to analyze the emission spectrum of the groups in the ECR plasma

[0030] 3) As shown in FIG. 1, a TiN transition layer is first grown on the silicon substrate by plasma-assisted electron beam evaporation reaction deposition or other methods, and the thickness of the transition layer is about 30-50 nm. In this embodiment, the thickness of the transition layer is about 50 nm.

[0031] 4) Using ethyl aluminum (TEAl), dimethyl zinc (DM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com