Method for preparing ordered mesoporous aluminum oxide in batch

An ordered mesoporous and alumina technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of difficult control of process conditions, difficulty in realizing industrialization, and large specific surface area, and achieve easy industrial scale-up production, low cost, and relatively low cost. The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

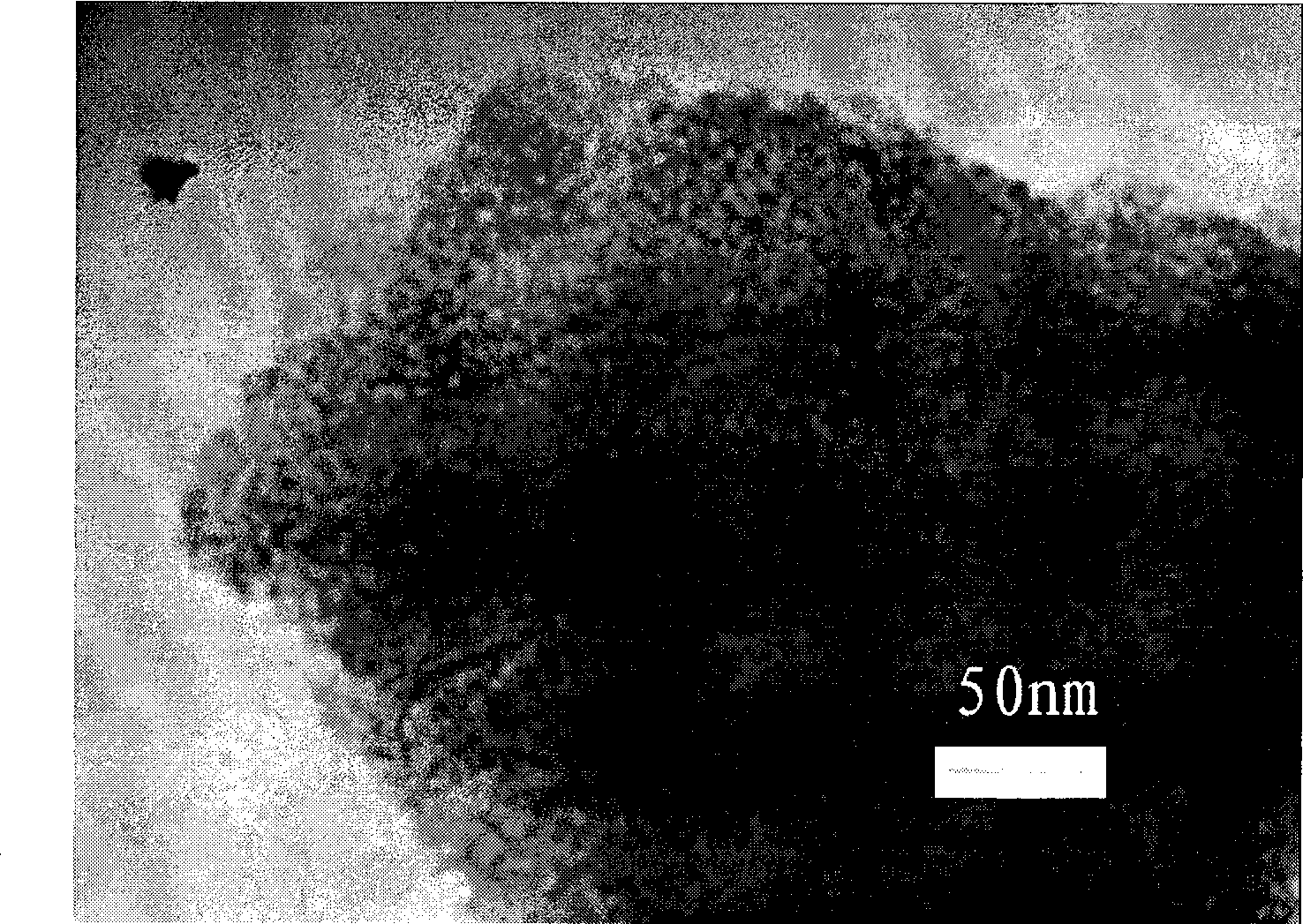

[0028] Add 0.9 g of polyethylene glycol to 2200 ml of the prepared 0.1 mol / l aluminum nitrate solution as a template; the reaction temperature is 70°C. Add 1650ml / l prepared 0.6mol / l ammonium carbonate solution at a rate of 8ml / min. When the pH value at the end of the reaction reaches 8, the inorganic precursor sol is obtained. The obtained inorganic precursor sol was aged at 70°C for 6 hours, and the aged inorganic precursor sol was filtered by a vacuum pump, and the filter cake was washed with water for 3 times, and dried at 80°C to obtain inorganic precursor powder. The obtained inorganic precursor powder is calcined. The specific calcination process is: under the protection of nitrogen, the temperature is raised to 330°C within 1 hour at a speed of 3°C / min1, maintained for 3 hours, and then the temperature is raised at a speed of 3°C / min1 within 1 hour under the condition of oxygen. to 550°C and maintained for 3 hours. Ordered mesoporous alumina is obtained after calcina...

Embodiment 2

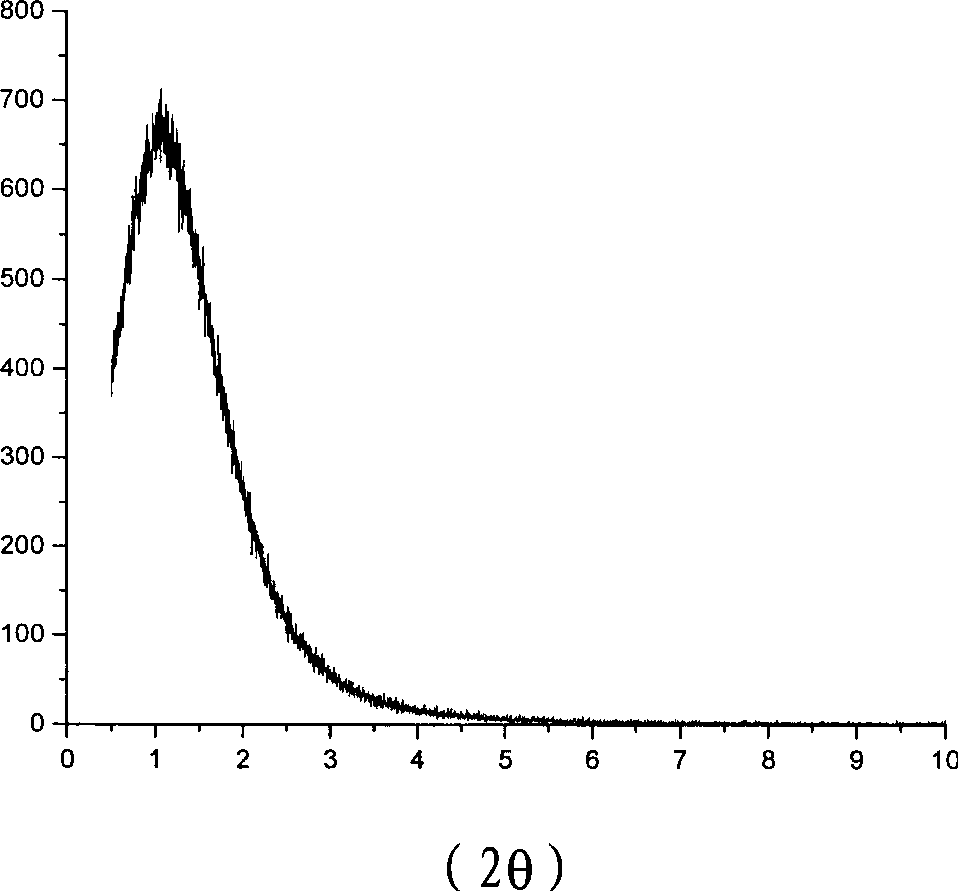

[0030] Add 0.9 g of polyethylene glycol to 2200 ml of the prepared 0.1 mol / l aluminum nitrate solution as a template; the reaction temperature is 60°C. Add 1650ml / l prepared 0.6mol / l ammonium carbonate solution at a rate of 8ml / min. When the pH value at the end of the reaction reaches 7, the inorganic precursor sol is obtained. The obtained inorganic precursor sol was aged at 50°C for 6 hours, the aged inorganic precursor sol was filtered by a vacuum pump, the filter cake was washed twice with water, and dried at 80°C to obtain inorganic precursor powder. The prepared alumina has a specific surface area of 262m2 / g, the pore volume is 0.28nm, and the pore diameter is 4.3nm. According to the nitrogen isotherm adsorption-desorption curve analysis, the adsorption curve is a type VI curve, and the pore distribution is relatively narrow, indicating strong order.

Embodiment 3

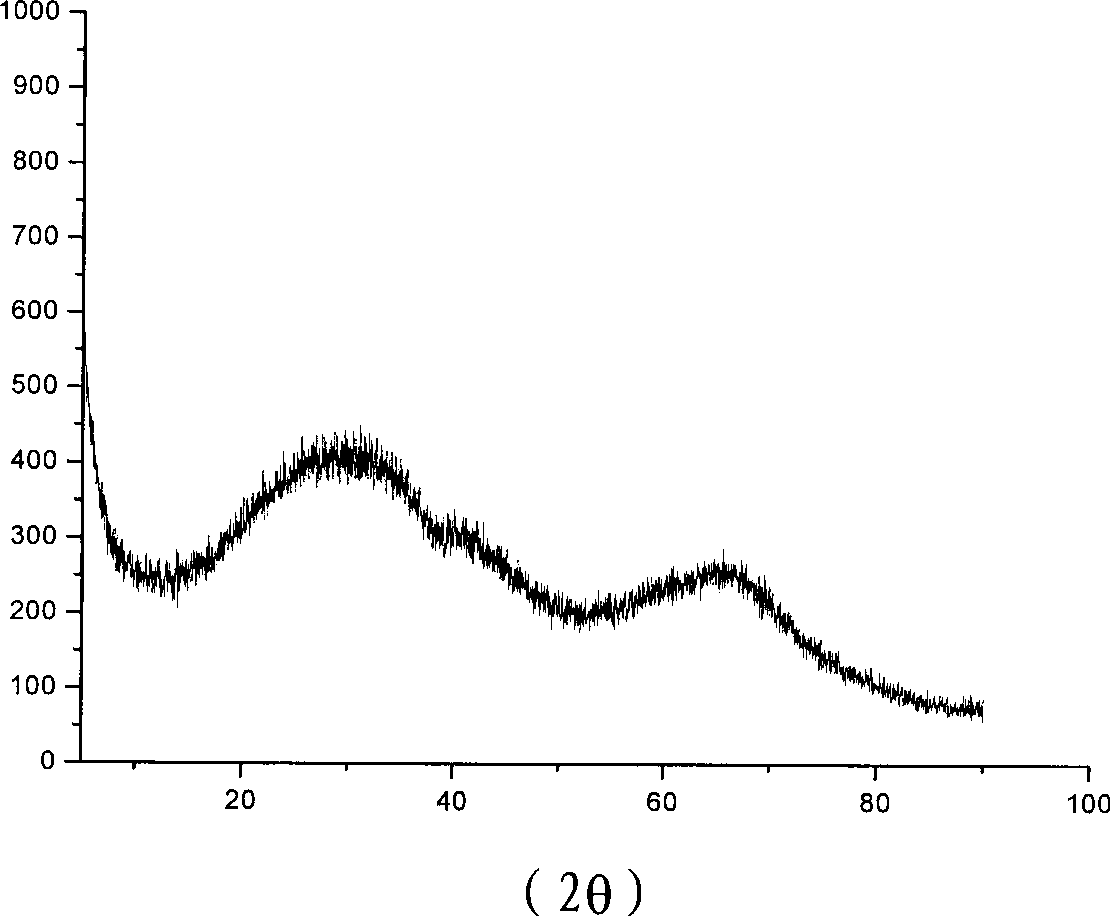

[0032] The operating parameters are the same as in Example 1, except that the aging temperature is 20°C. The prepared alumina has a specific surface area of 201m 2 / g, the pore volume is 0.28nm, and the pore diameter is 5.5nm. According to the nitrogen isotherm adsorption-desorption curve analysis, the adsorption curve is a VI curve, but the H ring is close to the I type, and the pore distribution moves relatively to the mesopore range and the pore distribution becomes narrower, indicating that the mesopore order is enhanced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com