Microbial preparation prepared by fermentation of stalk hydrolysate and use thereof

A microbial agent and ethanol technology, applied in the direction of microorganisms, microorganisms, and methods based on microorganisms, can solve the problems of increasing machinery, labor, energy consumption and cost, increasing production procedures, increasing process flow, etc., and achieve strong resistance to miscellaneous bacteria Pollution characteristics, save fermentation cost, and shorten the effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

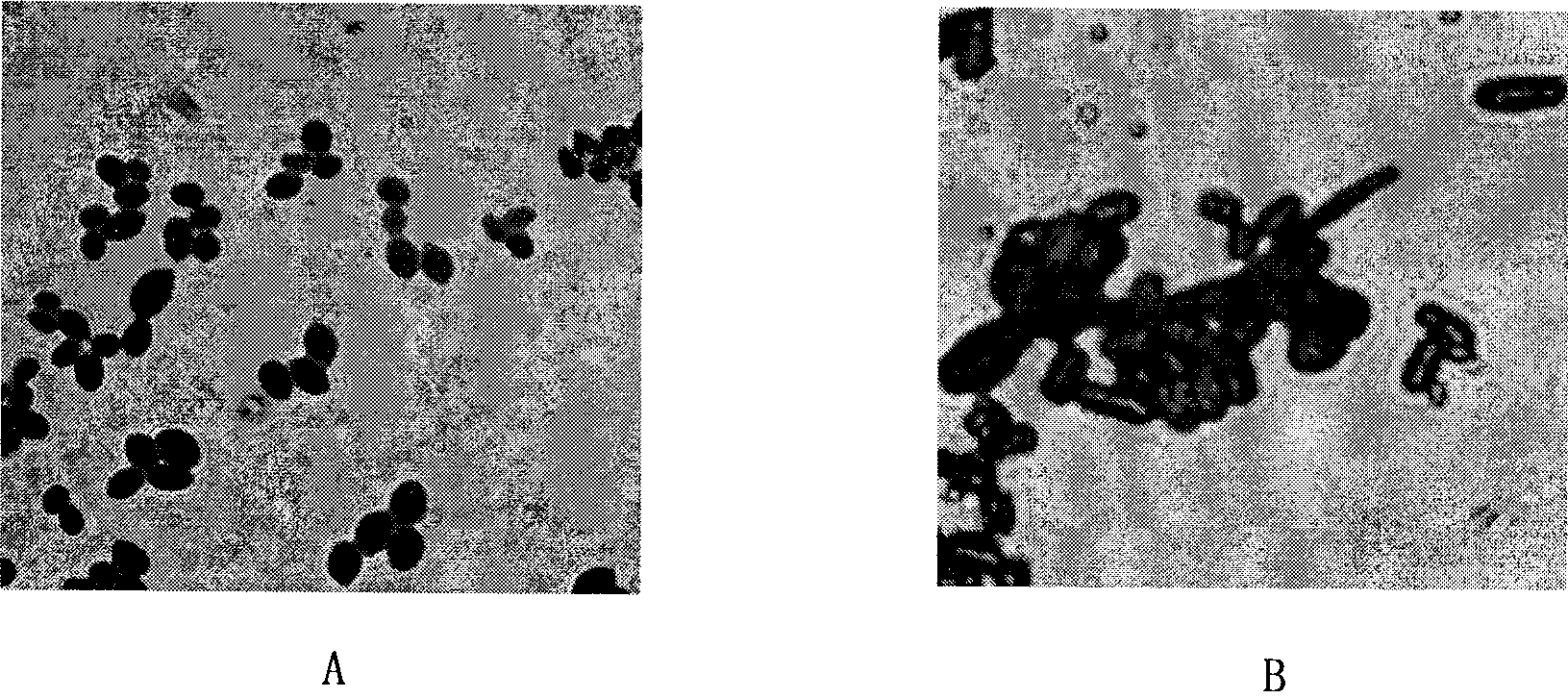

[0019] Embodiment 1, isolation and identification of bacterial strain

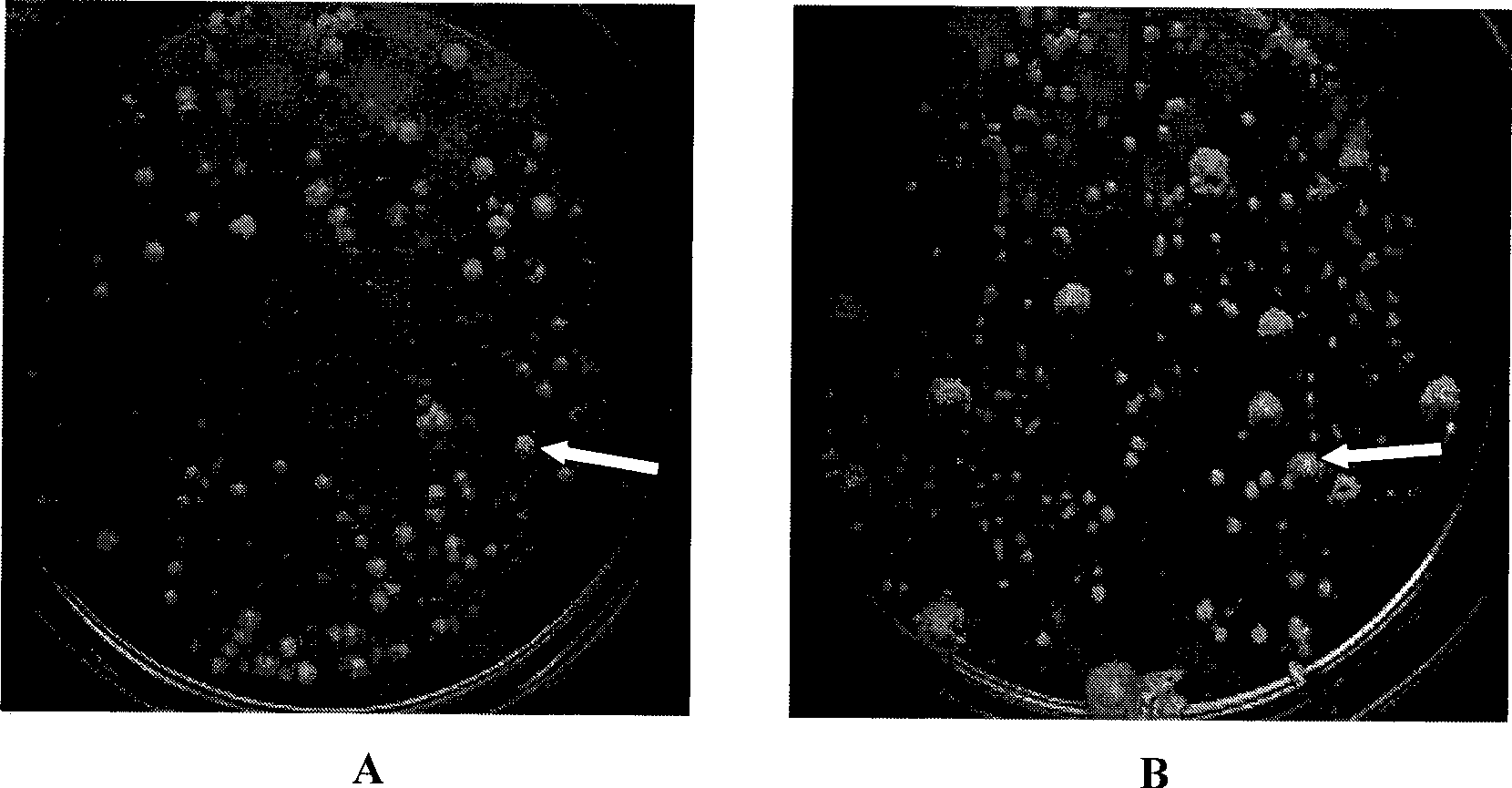

[0020] 1. Isolation of strains

[0021] In September 2006, five orchards near Xiangshan, Haidian District were selected, and surface soil samples within the projection range of the canopy under the fruit trees were collected respectively, and put into clean plastic bags for retrieval.

[0022] Selective culture was carried out with dilute acid hydrolyzate of straw as substrate to enrich ethanol fermenting bacteria. The dilute acid hydrolyzate of straw is obtained as follows: corn straw is crushed through a 20-mesh sieve, 1% by volume of dilute sulfuric acid is added, and the solid content of 10% by mass is hydrolyzed at 110° C. for 40 minutes. Weigh 5g of the recovered soil samples, add the prepared dilute acid hydrolyzate in an amount of 5% by mass, group them according to the numbers of different sampling points, and then cultivate them. The culture temperature is 34°C, the rotation speed is 70r / min, a...

Embodiment 2

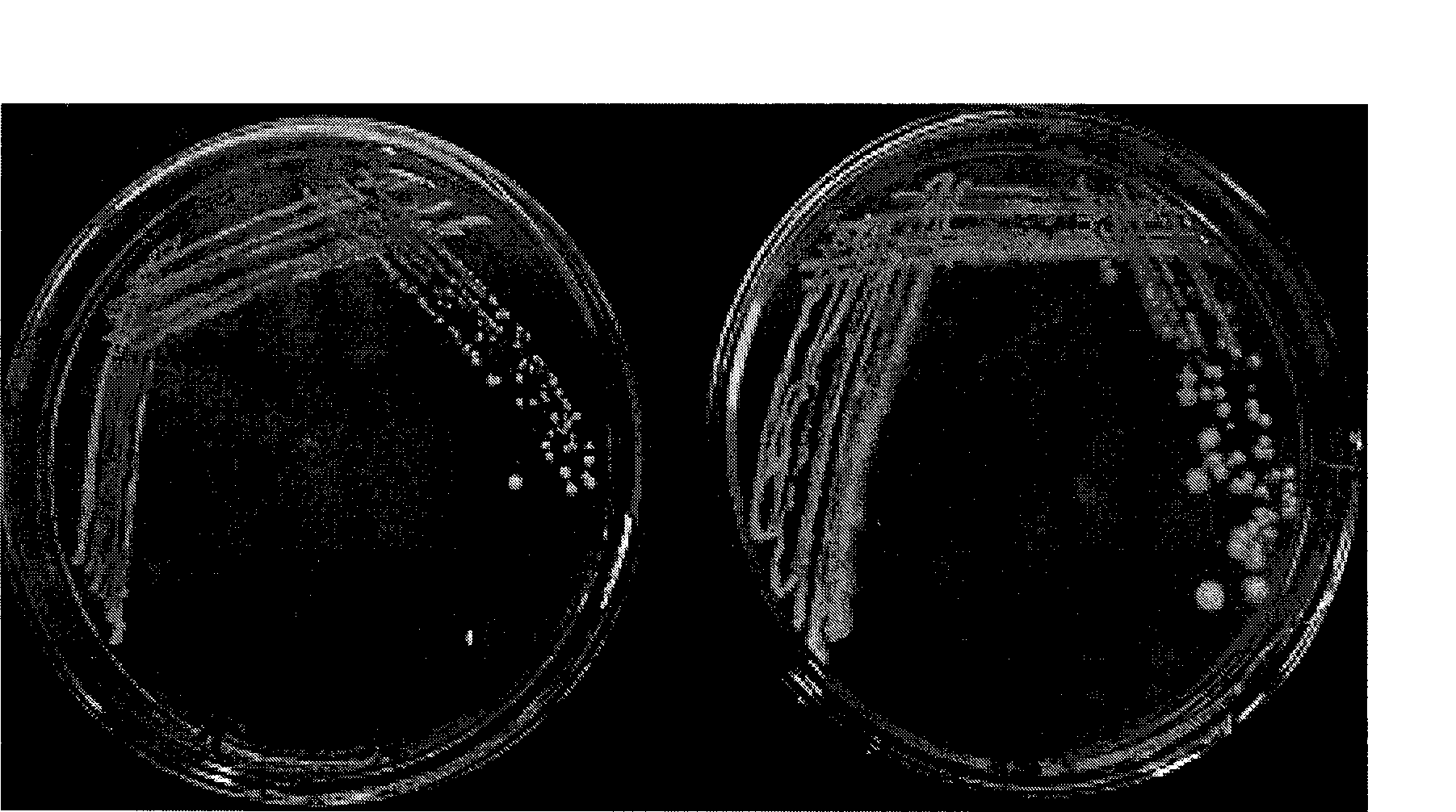

[0037] Embodiment 2, the preparation of microbial bacterial agent

[0038] Trichoderma konigii Oudem ACCC 30167 was inoculated in potato dextrose agar liquid medium at 150r / min, and activated at 30°C for 10h. Yeast (Trichosporon aquatic) M04 CGMCC2443 was inoculated in liquid YEPD medium at 150r / min, and activated at 30°C for 24h. Kluyveromyces (Saccharomyces kluyveri) M02 CGMCC 2442 was inoculated in liquid YEPD medium at 150r / min, and activated at 30°C for 24h. Trichoderma konigii Oudem (Trichoderma konigii Oudem) ACCC 30167 bacterium liquid, saccharomycete (Trichosporon aquatile) M04 CGMCC 2443 bacterium liquid and Kluyveromyces (Saccharomyces kluyveri) M02 CGMCC 2442 bacterium liquid are mixed to prepare microbial inoculum, The colony-forming unit ratio of Trichoderma konigii Oudem ACCC 30167, Trichosporonaquatile M04 CGMCC 2443 and Saccharomyces kluyveri M02 CGMCC2442 in the agent was 1:1:1.

Embodiment 3

[0039] Embodiment 3, the preparation of microbial bacterial agent

[0040] Trichoderma konigii Oudem ACCC 30167 was inoculated in potato dextrose agar liquid medium at 150r / min, and activated at 30°C for 18h. Yeast (Trichosporon aquatic) M04 CGMCC2443 was inoculated in liquid YEPD medium at 150r / min, and activated at 30°C for 24h. Kluyveromyces (Saccharomyces kluyveri) M02 CGMCC 2442 was inoculated in liquid YEPD medium at 150r / min, and activated at 30°C for 24h. Trichoderma konigiiOudem (Trichoderma konigiiOudem) ACCC 30167 bacterium liquid, saccharomycete (Trichosporon aquatile) M04 CGMCC 2443 bacterium liquid and Kluyveromyces (Saccharomyces kluyveri) M02 CGMCC 2442 bacterium liquid are mixed to prepare microbial inoculum. The colony forming unit ratio of Trichoderma konigii Oudem ACCC30167, Trichosporonaquatile M04 CGMCC 2443 and Saccharomyces kluyveri M02 CGMCC2442 in the bacterial agent was 1:2:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com