Supercritical CO2 extraction of grape-kernel oil and method for extracting oligoprotoanthocyanidin by solvent process

A technology for oligomeric proanthocyanidins and grape seed oil, which is applied in the fields of supercritical CO2 extraction of grape seed oil and solvent extraction of oligomeric proanthocyanidins, can solve problems such as unsatisfactory research results, and achieve pure naturalness and good thermal stability. and storage, the effect of no solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

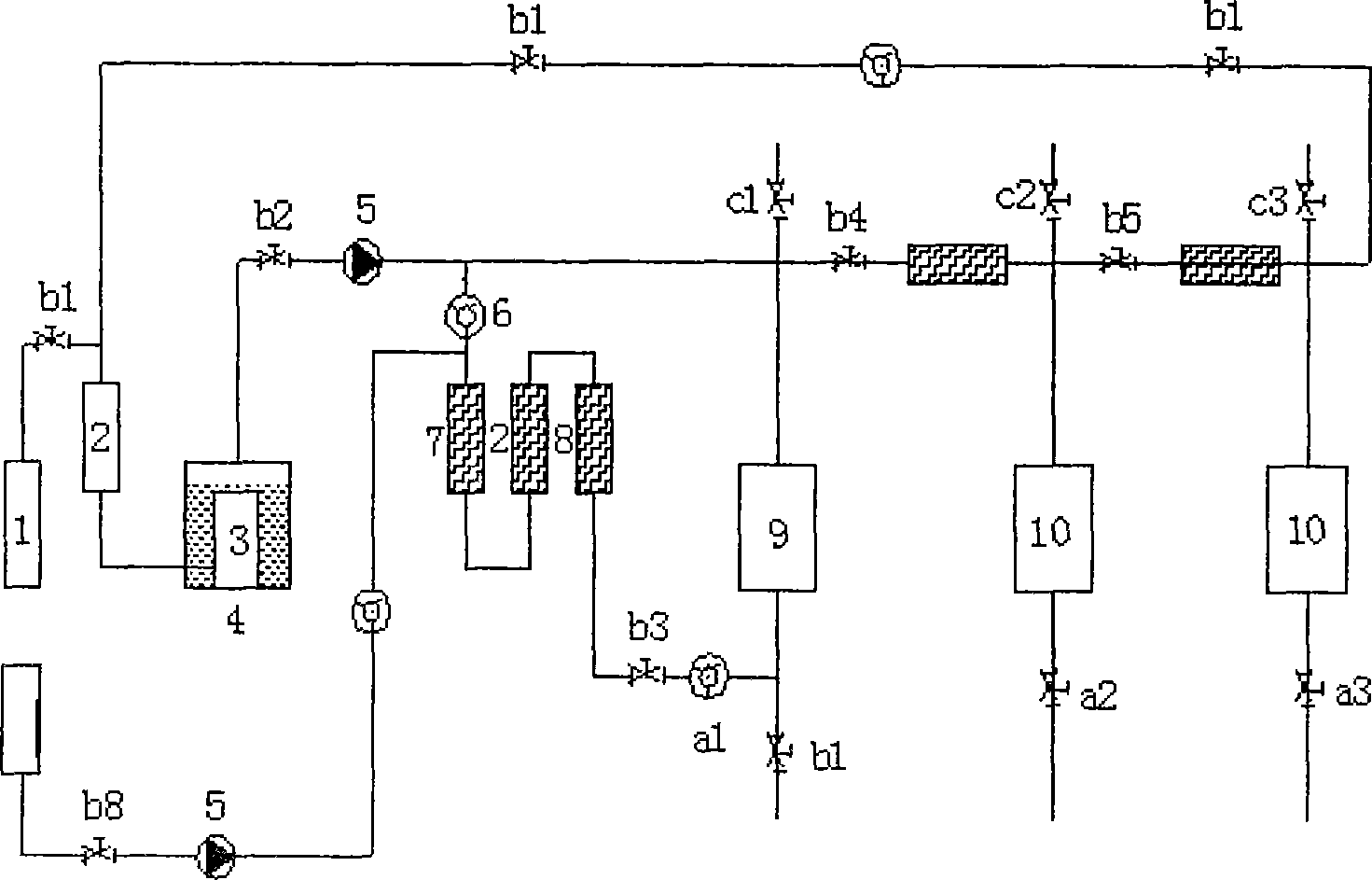

[0026] In the experiment, the grape seed powder obtained after crushing and drying was used as raw material, and supercritical CO was used to 2 (SC-CO 2 ) extraction technology, the flow of the test device is as follows figure 1 shown. The supercritical extraction device is mainly composed of the following parts: CO 2 Gas cylinder 1, filtration and purification device 2, storage tank 3, cold box 4, flow plunger metering pump 5, check valve 6, mixer 7, preheater 8, extraction kettle 9, separator 10, etc.

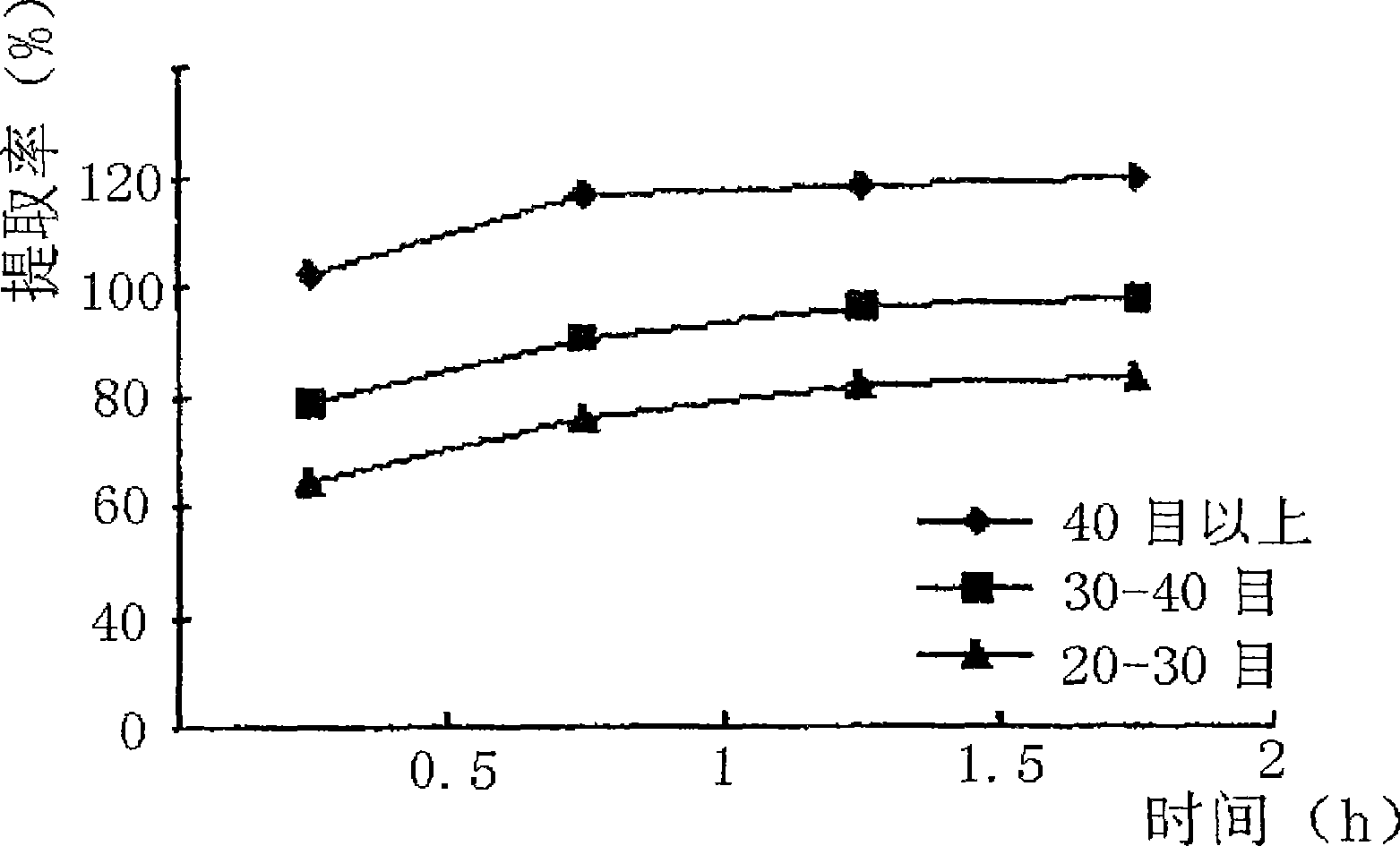

[0027] Accurately weigh the grape seed powder with crushed particle size of 20 mesh, 40 mesh and 60 mesh respectively, put them in the extractor, and carry out dynamic extraction under the set extraction conditions. Supercritical CO with grape seed oil dissolved 2 After decompression and heating, it is separated from the grape seed oil. After the extraction is completed, the weight of the extract is accurately weighed, and the oil content in the grape seed powder is measur...

Embodiment 2

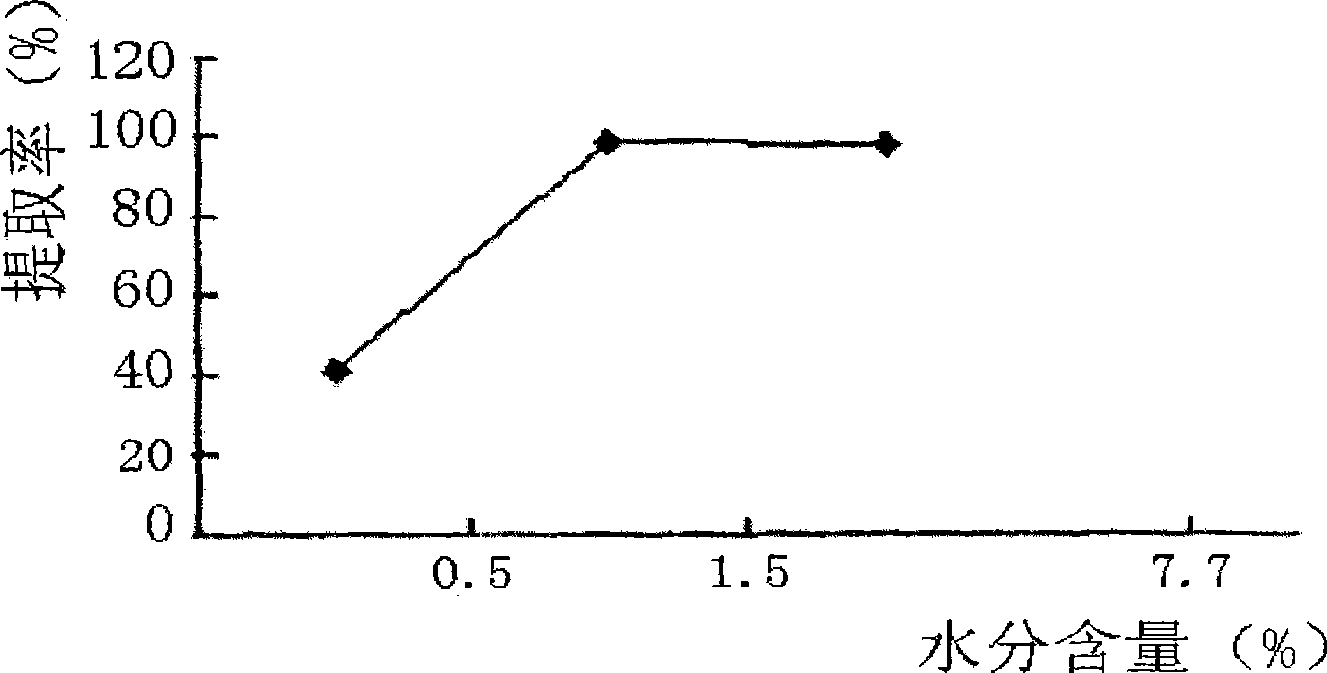

[0031] The extracts in the actual system will contain a certain amount of water, and the oil and fat are extracted using the carbon dioxide critical fluid. The water content in the material is an important factor affecting the extraction yield. Grape seeds with water content of 0.5%, 4.5% and 7.7% were selected for extraction such as image 3 , at a pressure of 30MPa and a temperature of 45°C, CO 2Under the extraction condition of flow rate of 10L / h, 40 mesh grape seed oil was collected after 90 minutes, and the yields of grape seed oil were 40%, 98.53% and 97.62% respectively, and there was white precipitate in the product when the water content was high Precipitation, and the pipeline freezes up. It can be seen that the water content cannot be too high or too low, and the extraction rate of grape seed oil is the highest when it is about 4.5%, and the quality is also the best.

Embodiment 3

[0033] Other conditions are constant, as the pressure situation increases, the oil rate also increases eventually, and the time used also decreases, such as Figure 4 , at 30MPa, the extraction rate reached 98.53% after 90 minutes, 60% and 82% at 20MPa and 25MPa, respectively, and then both reached the maximum after 30 minutes and 60 minutes. This is because as the pressure increases, the supercritical CO 2 As the density increases, its solvency also increases, which strengthens the relationship between grape seed oil and supercritical CO 2 The solvation improves the extraction efficiency and shortens the equilibrium time relatively. However, when the pressure is relatively high, the pigment content in the extract will increase and the color will deepen, which will have a certain impact on the quality of the product. Considering the practicability of production, it is better to choose the extraction pressure in the range of 25-30MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com