Apparatus for detecting contact corona and arc-drawing of high voltage switch cabinet

A high-voltage switchgear and detection device technology, which is applied in the direction of high-voltage/high-current switches, measuring devices, substation/switch layout details, etc., can solve problems such as arrester explosion, explosion damage, short circuit, etc., to prevent switchgear failure and reduce malignant Accidents, the effect of accurate detection means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

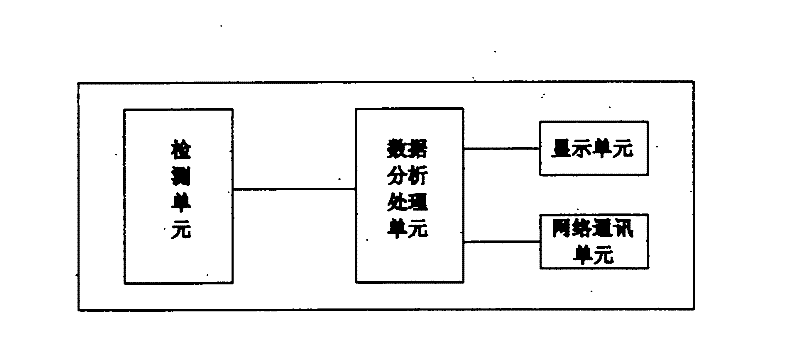

[0020] figure 1 In the structural block diagram of the present invention, the high-voltage switchgear contact corona and arc detection device includes a detection unit, a data analysis and processing unit, a display unit, a network communication unit and a power supply unit (not shown in the figure), wherein the detection unit adopts a sensor Output the switch cabinet contact arc signal to the data analysis and processing unit. After the data analysis and processing unit analyzes and processes the input signal, one output is sent to the display unit for detection result display, and one output is sent to the network communication unit to send the detection data to the upper position through the network. machine, the power supply unit supplies power to each unit of the device.

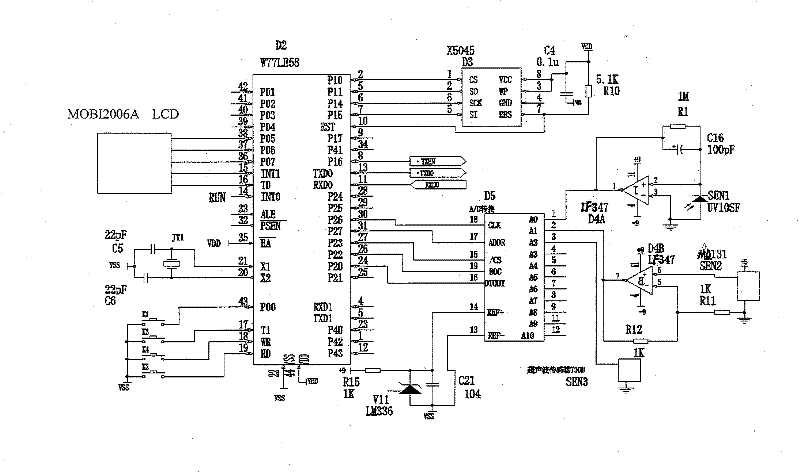

[0021] figure 2 In the schematic circuit diagram of the embodiments of the detection unit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com