Biological functional multilayer film modified electrode and method for making same

A technology for modifying electrodes and multilayer films, which is applied in the direction of material analysis, instruments, and measuring devices through electromagnetic means, and can solve the problems of poor biocompatibility of inorganic nanosheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

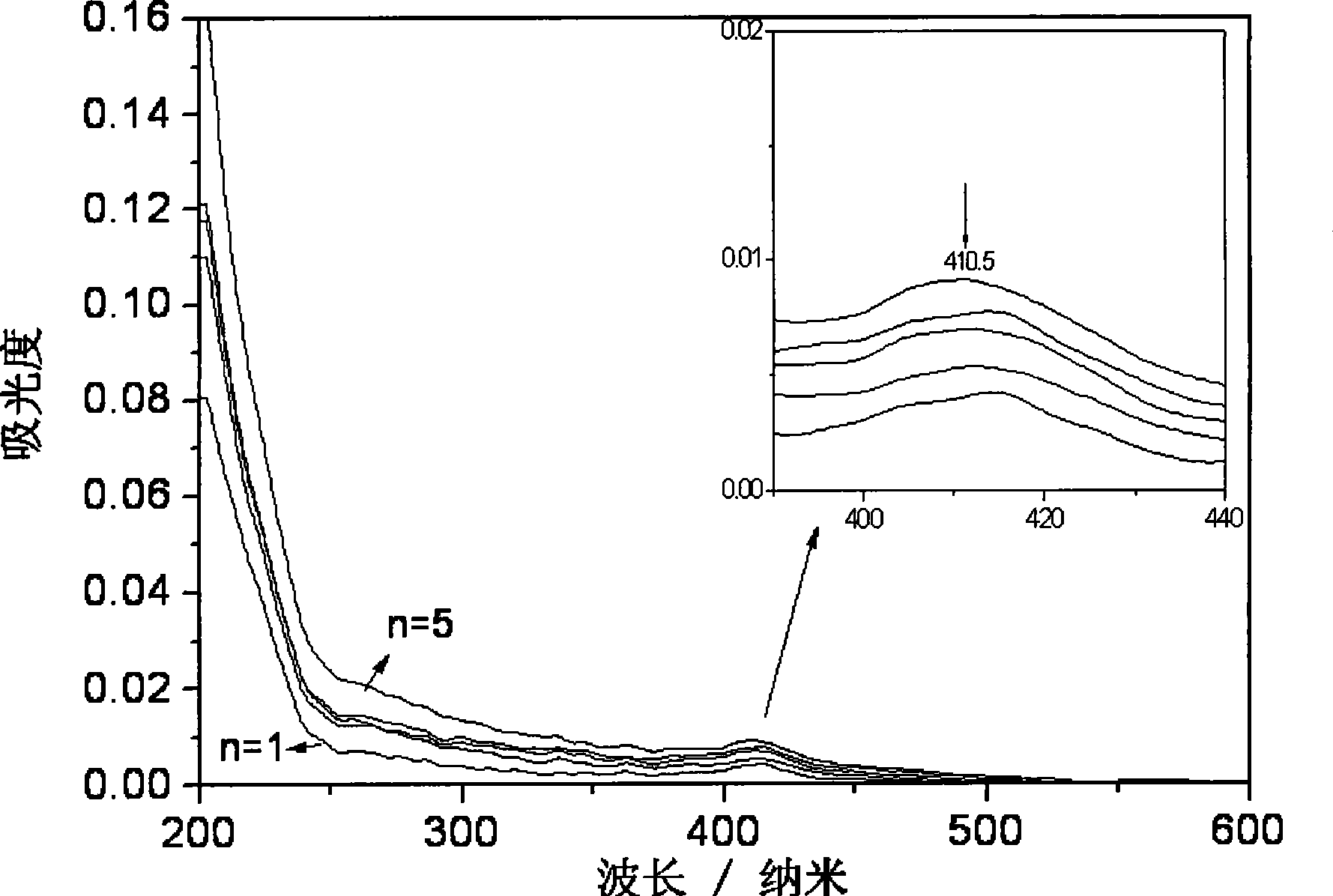

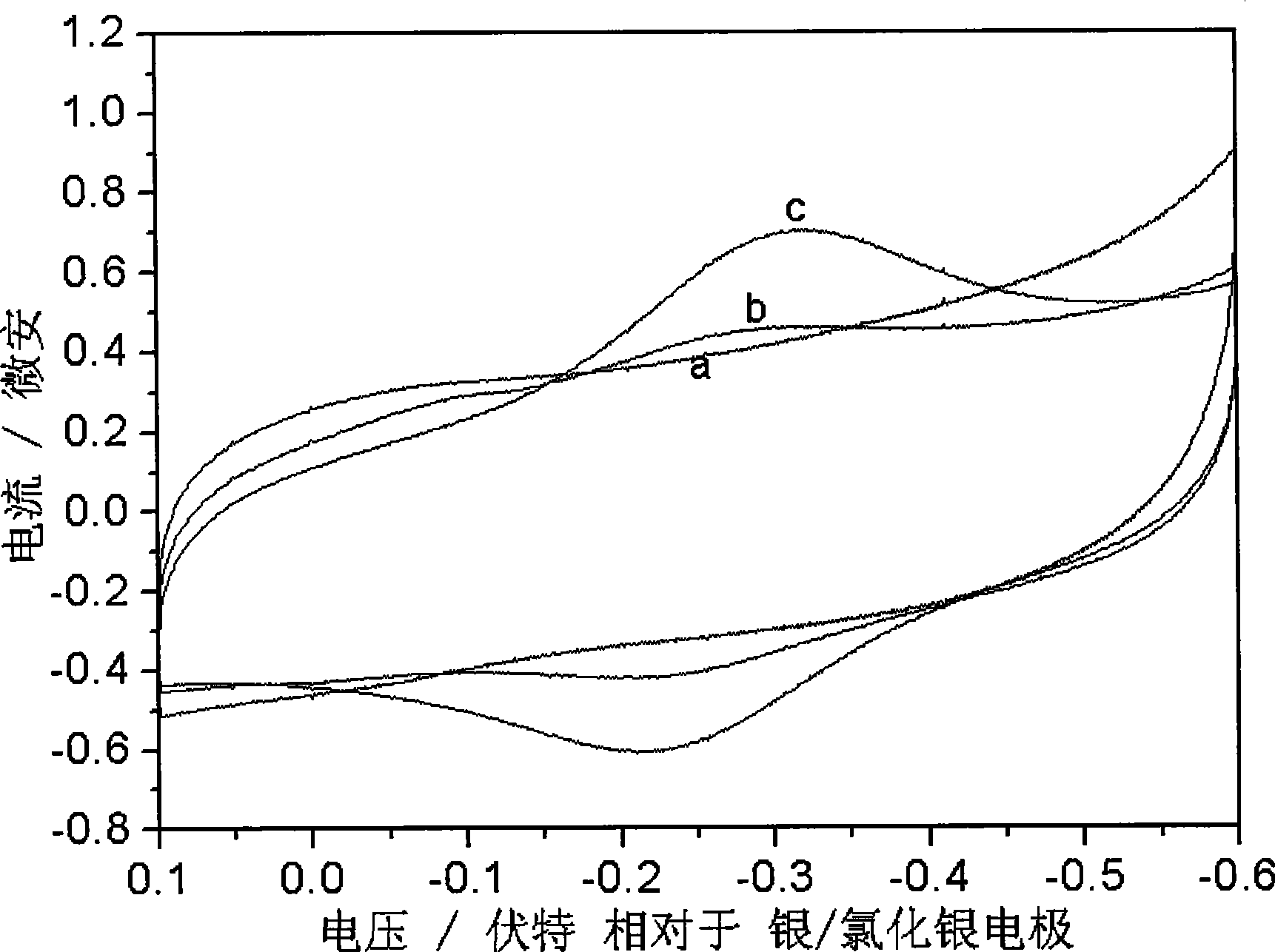

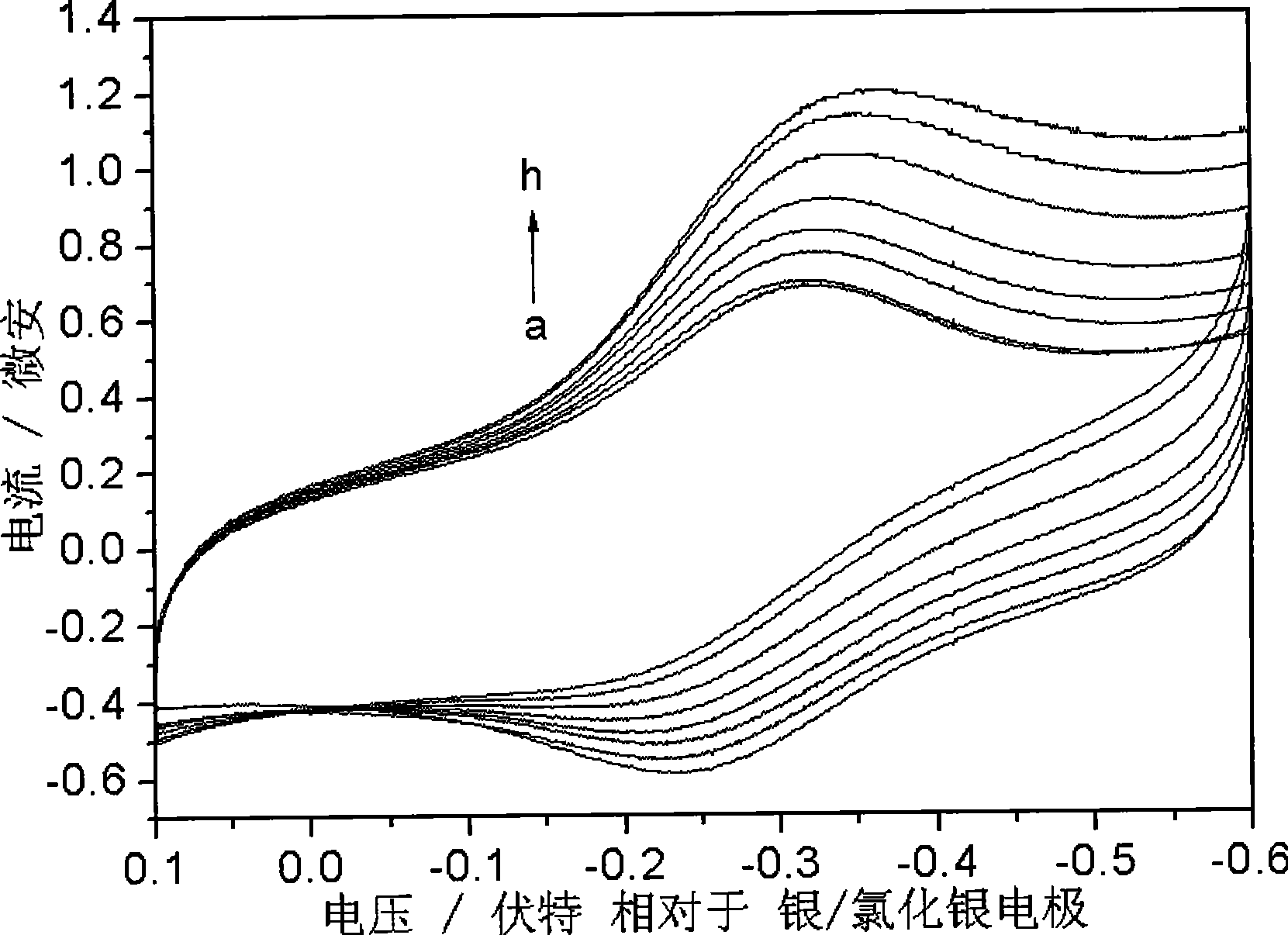

Embodiment 1

[0031] A. Preparation of magnesium aluminum hydrotalcite nanosheets: Weigh 0.05mol of Mg(NO 3 ) 2 and 0.0125mol of Al(NO 3 ) 3 Dissolve in 100mL deCO2 2 of distilled water. Weigh 0.2mol NaOH and dissolve in 100mL deCO2 2 distilled water to make an alkaline solution with a concentration of 2.0mol / L. The above two solutions were placed in N 2 Dropped into the deCO2 at the same time under protection 2 In the distilled aqueous solution of the solution, adjust the rate of addition of the NaOH solution while adding the salt solution dropwise, and keep the pH value of the system at 7 during the dropwise addition. Put the resulting slurry in N 2 Crystallize at 50°C for 12 hours under protection, and deCO 2 Wash and filter with distilled water, and vacuum-dry the filter cake at room temperature for 12 hours to obtain nitrate-intercalated hydrotalcite powder; weigh 0.05 g of the obtained hydrotalcite product, dissolve it in 100 mL of formamide, heat and stir at 90 ° C for 1.5 h...

Embodiment 2

[0035] A. The preparation method of magnesium aluminum hydrotalcite nanosheets is the same as that in Example 1.

[0036] B. (Magnesium Aluminum Hydrotalcite Nanosheets / Glucose Oxidase / Chitosan / Glucose Oxidase) 3 Preparation of multilayer film modified platinum electrode: clean the platinum electrode, and then use N 2 Blow dry; immerse the electrode in 30g / L sodium polystyrene sulfonate aqueous solution for 15 minutes, take it out, rinse with distilled water, and use N 2 Blow dry; immerse the treated electrode in the magnesium aluminum hydrotalcite nanosheet solution with a concentration of 0.5g / L for 15 minutes, take it out, rinse with distilled water, and wash with N 2 Blow dry; then immerse the electrode in a glucose oxidase aqueous solution with a concentration of 1.0g / L for 20 minutes, take it out, rinse with distilled water, and rinse with N 2 Blow dry; then immerse the electrode in a chitosan solution with a concentration of 0.5g / L and take it out after 20 minutes, ri...

Embodiment 3

[0039] A. Preparation of manganese dioxide nanosheets: 200mL containing 0.6mol / L NaOH and 1.0mol / L H 2 o 2 The mixed solution was quickly added to 100mL containing 0.3mol / L Mn(NO 3 ) 2 solution, stirred and reacted for 20 minutes, filtered, and the filter cake was transferred to a polytetrafluoroethylene container; 30 mL of NaOH solution with a concentration of 2.0 mol / L was added, stirred to form a paste, and the polytetrafluoroethylene container was sealed in a 50 mL hydrothermal In the kettle, hydrothermal treatment was carried out at 150°C for 15 hours; the hydrothermal kettle was naturally cooled to room temperature, the kettle was opened for suction filtration, the filter cake was washed with distilled water until the pH value of the filtrate was 8, and the filter cake was dried in an air atmosphere at 70°C for 6 hours. Obtain layered manganese dioxide; Weigh 4g of layered manganese dioxide solid powder and add to 300mL concentration of 1.0mol / L HNO 3 solution, stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com