Polyfunctional hydrocarbon oil composition

A multifunctional and compositional technology, applied in lubricating compositions, organic non-surface-active detergent compositions, petroleum industry, etc., can solve problems such as increased amount of abrasive powder, loss of oil film, hindered lubricity, etc., and achieve resin adaptability The effect of improving, improving atomization characteristics, and increasing processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

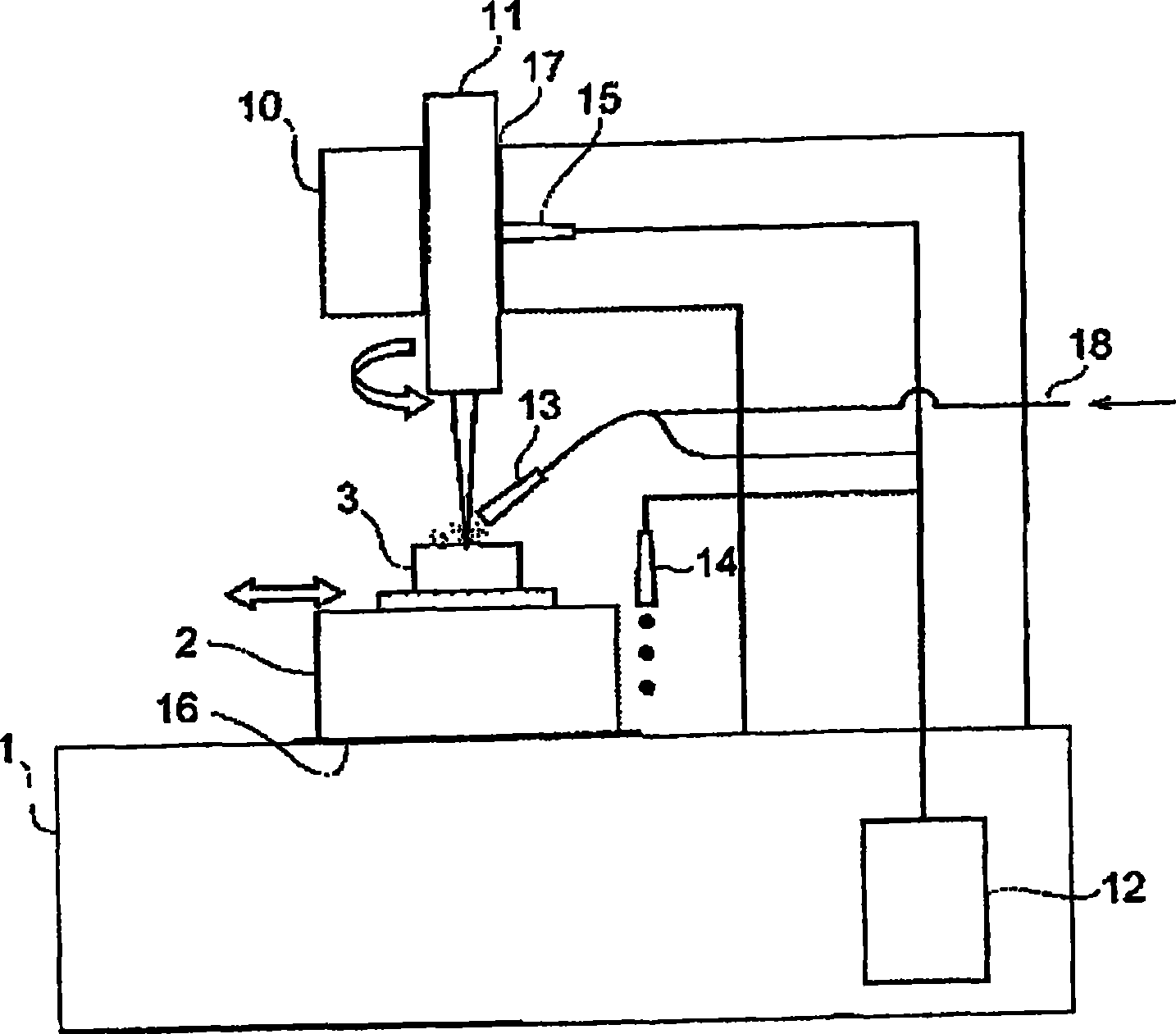

Method used

Image

Examples

Embodiment 1

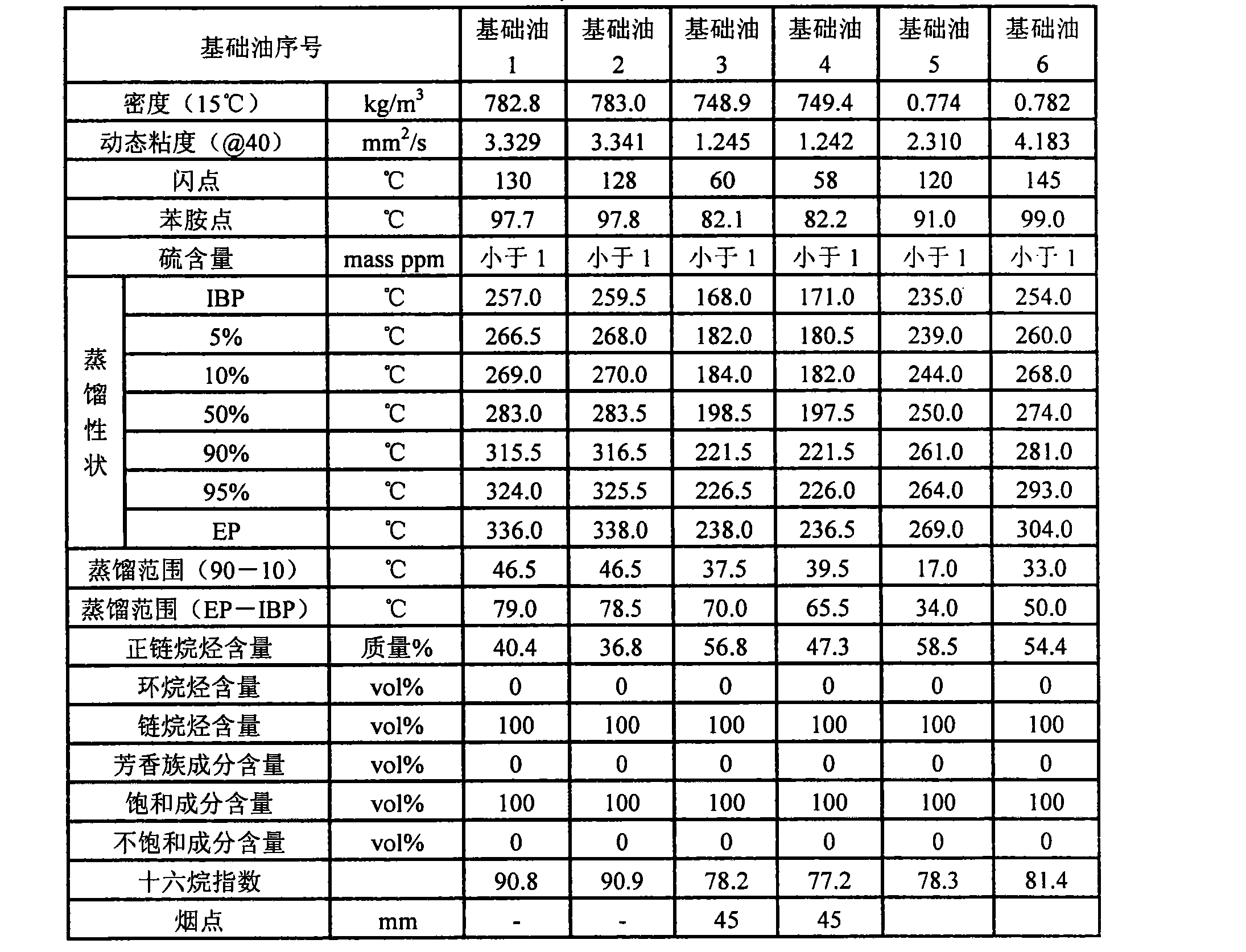

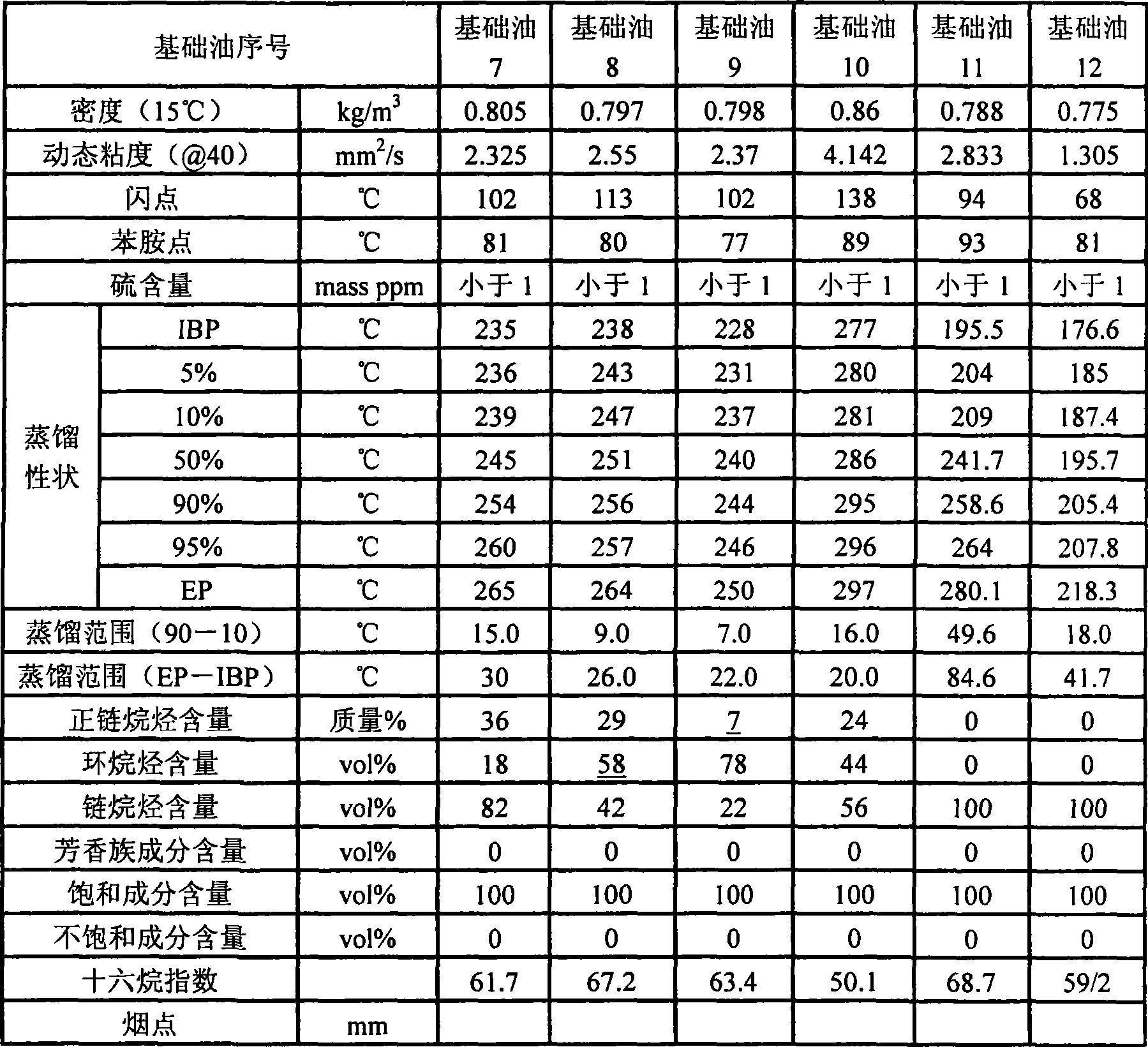

[0314] In this example, a test was performed as an aluminum rolling oil.

[0315] The base oils in Table 1 were blended with butyl stearate, lauryl alcohol, and oleic acid as oily agents in the amounts shown in Table 2 to prepare metalworking oils.

[0316] Next, the aluminum rolling test, the determination of the odor, and the oil agent removal test were carried out with respect to the obtained processing oil.

[0317] All the results are described in Table 3 below.

[0318] Test method for rolling process:

[0319] Using aluminum (JIS A1050; thickness 0.15 mm, width 78 mm), rolling was performed at a rolling speed of 250 m / min and a reduction ratio of 35%, and the load required for processing was measured. When the required load is small, the workability becomes good, which is preferable.

[0320] Determination method of odor:

[0321] The odor was judged in the state which heated the sample oil to 40 degreeC.

[0322] 10 judges made the evaluation, an...

Embodiment 2

[0334] In this example, a test was performed as an aluminum heat sink processing oil.

[0335] The base oils in Table 1 were blended with butyl stearate, lauryl alcohol, 1-tetradecene, and tetrapropylene glycol in the amounts shown in Table 2 to prepare metalworking oils.

[0336] Next, a test of processing aluminum fins was performed on the obtained processing oil. That is, as the lubricity, the coefficient of friction was evaluated. Odor and dryness were also evaluated.

[0337] The results are all described in Table 4.

[0338] The test methods of the test items are as follows.

[0339] Lubricity test method:

[0340] Material Aluminum JIS A1050 material

[0341] The coefficient of friction was evaluated using the Bauden test.

[0342] Load 250g, sliding speed 100mm / s

[0343] Determination method of odor:

[0344] The odor was judged in the state which heated the sample oil to 40 degreeC.

[0345] 10 judges made the evaluation, and the scor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com