Ion-exchange denitrification and phosphorus removal advanced treatment method

A technology of ion exchange and anion, which is applied in the field of water pollution purification for deep denitrification and dephosphorization, can solve the problems of small adsorbent capacity, metal loss, poor selectivity, etc., achieve low regeneration cost, reduce operating cost, and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

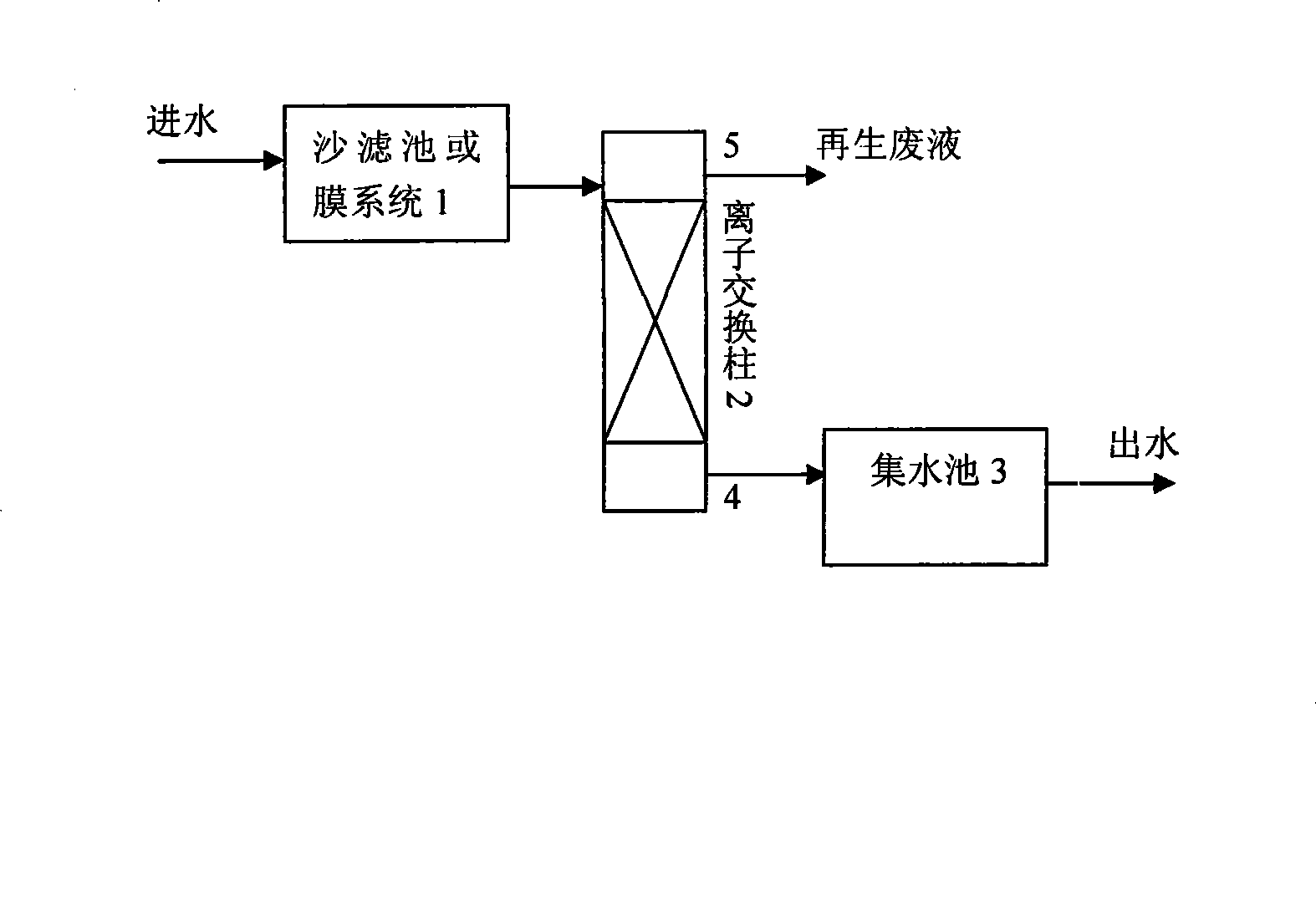

Image

Examples

Embodiment 1

[0017] The water quality characteristics of the secondary nitrification effluent of a certain municipal sewage plant are shown in Table 1. Using the present invention as advanced treatment, the ion exchange effluent index at 300BV is shown in Table 1.

[0018] Table 1 Index values before and after ion exchange treatment of secondary treatment effluent of a municipal sewage plant

[0019] COD Cr (mg / L) BOD 5 (mg / L) NO x -N(mg / L) TP(mg / L) SS(mg / L) Before processing 50 20 8 1.8 15 After treatment 30 12 1.1 0.1 1.4

Embodiment 2

[0021] The lakes in a city in Beijing are seriously eutrophication, and the water quality has reached the Class V water standard. The water quality indicators are shown in Table 2. Using the present invention to filter and process the nutrient water body, the effluent water quality at 1000 BV is shown in Table 2.

[0022] Table 2 Index values of a certain eutrophic lake water before and after treatment by ion exchange process

[0023] COD Cr (mg / L) BOD 5 (mg / L) NO x -N(mg / L) TP(mg / L) Before processing 43 11 2.8 0.4 After treatment 35 8 0.19 0.02

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com