Composite self-curing material of dicalcium silicate, preparation and uses thereof

A self-curing technology of dicalcium silicate, which is applied to human hard tissue defect filling and repairing materials. It will be used in the field of dicalcium silicate for a long time, and can solve the problems of lack of biological activity, lack of long-term structural support, and no promotion of bone regeneration. , to achieve the effects of excellent biocompatibility, excellent biological performance and excellent biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Blending liquid preparation

[0044] Weigh 1.0 g of analytically pure sodium bicarbonate and dissolve it in 99.0 mL of deionized water to obtain a 1.0 wt.% sodium bicarbonate solution, sterilize, seal it in a sterile bottle, and set aside.

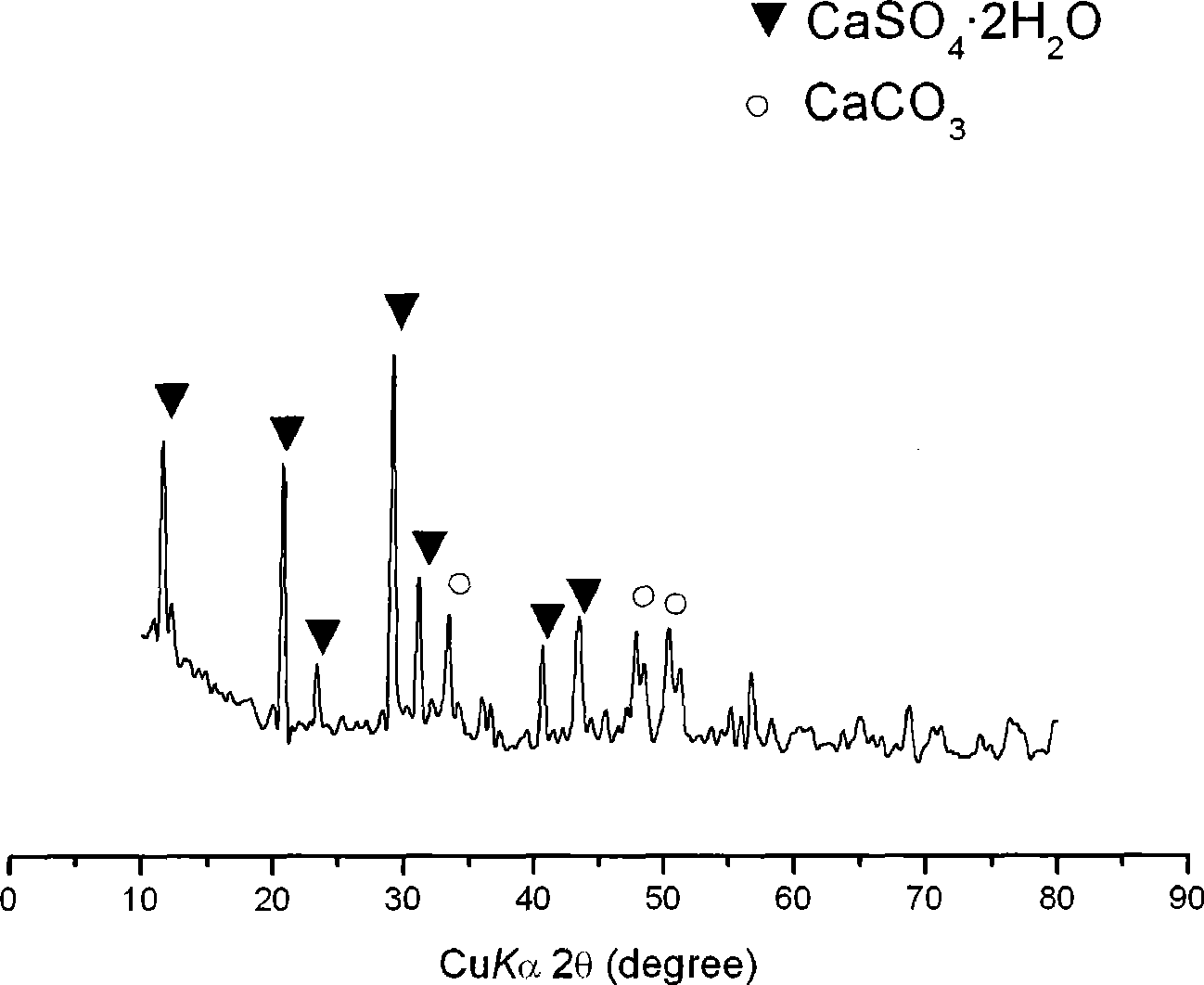

[0045] 2) Preparation of dicalcium silicate / calcium sulfate hemihydrate composite self-curing material:

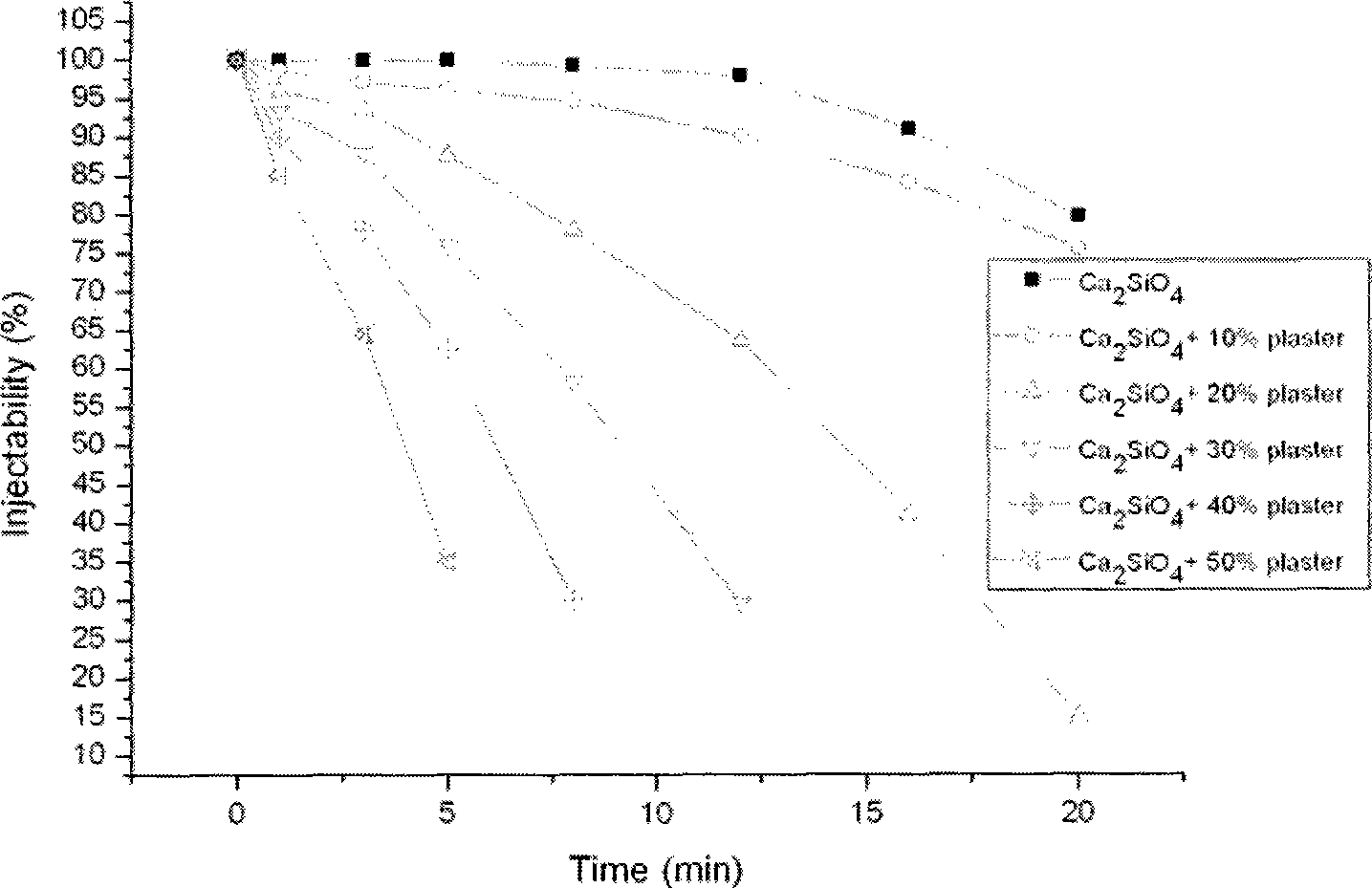

[0046] The dicalcium silicate / calcium sulfate hemihydrate composite material powder with a calcium sulfate hemihydrate content of 30wt.% and the blending solution are fully blended for 0.5-1 minute at a ratio of liquid to solid mass ratio of 1.2:1 to obtain micro Dicalcium silicate / calcium sulfate hemihydrate composite self-curing material for invasive treatment. The self-curing material can reach the initial setting in about 20 minutes after being injected into the defect site, the self-curing material slurry can be injected within 15 minutes, the compressive strength of the self-curing material can reach 9.6∽36.0MPa, and t...

Embodiment 2

[0048] 1) Blending liquid preparation

[0049] Weigh 1.0 g of analytically pure sodium bicarbonate and dissolve it in 99.0 mL of deionized water to obtain a 1.0 wt.% sodium bicarbonate solution, sterilize, seal it in a sterile bottle, and set aside.

[0050] 2) Preparation of dicalcium silicate / calcium sulfate hemihydrate composite bone defect filling material:

[0051] The dicalcium silicate / calcium sulfate hemihydrate composite material powder with a calcium sulfate hemihydrate content of 60wt.% and the blending solution are fully blended at a liquid-solid mass ratio of 1.2:1, and injected into the mold for 0.5-1 minute. ℃ and 100% humidity conditions for curing for more than 7 days, after which the dicalcium silicate / calcium sulfate hemihydrate composite material pellets or small discs (C 2 S / plaster Pellets). The compressive strength of the pellets or discs can reach 7.0∽9.0MPa, and the degradation rate can reach more than 80% after 21 days, and has good biological activ...

Embodiment 3

[0053] 1) Preparation of blending solution

[0054] The simulated body fluid is used as the blending solution, and the ion concentration of the simulated body fluid is shown in Table 2 (pH=7.25-7.4):

[0055] Table 2

[0056] Ion species Na + K + Mg 2+ Ca 2+ Cl - HCO 3 - HPO 4 2- ion concentration

(mmol / L) 142.0 5.0 1.5 2.5 148.8 4.2 1.0

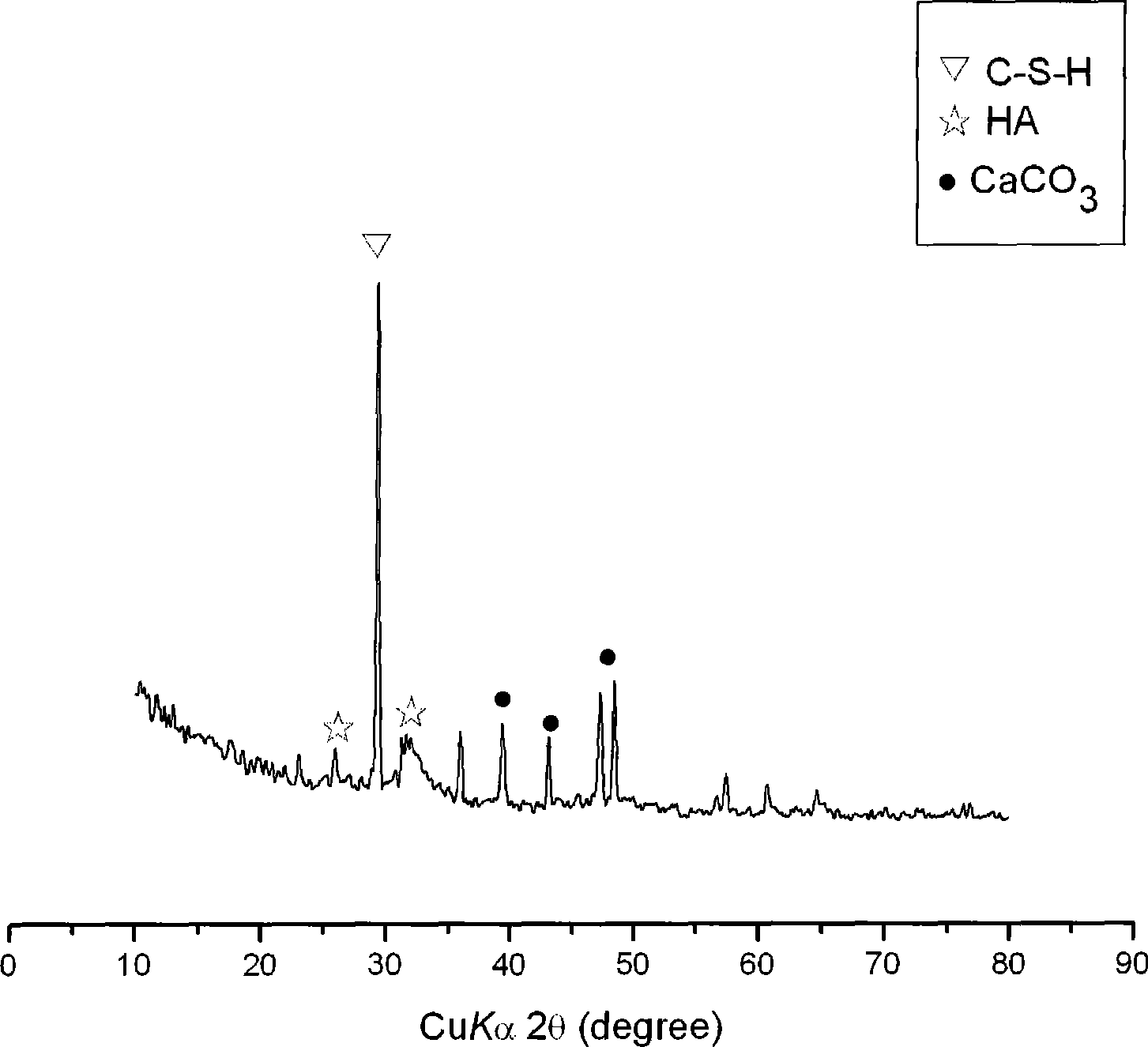

[0057] 2) Preparation of Dicalcium Silicate / Calcium Sulfate Hemihydrate Composite Degradable Material

[0058] Fully blend the dicalcium silicate / calcium sulfate hemihydrate composite material powder with a calcium sulfate hemihydrate content of 5-95wt.% and the blending solution at a ratio of 0.8-1.2:1 by liquid-solid mass ratio for 0.5-1 minute, inject The mold was cured for more than 7 days at 37°C and 100% humidity, and then the dicalcium silicate / calcium sulfate hemihydrate composite material pellets (C 2 S / plaster Pellets). The compressive strength of the pellets can reach 7.3∽37....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com