High-efficient wet-type ammonia recovering method desulfuration method with oxidation and concentration processes outside tower and device thereof

A desulfurization device and ammonia recovery technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high anti-corrosion requirements for equipment, low purity of ammonium sulfate products, and difficult promotion and use of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

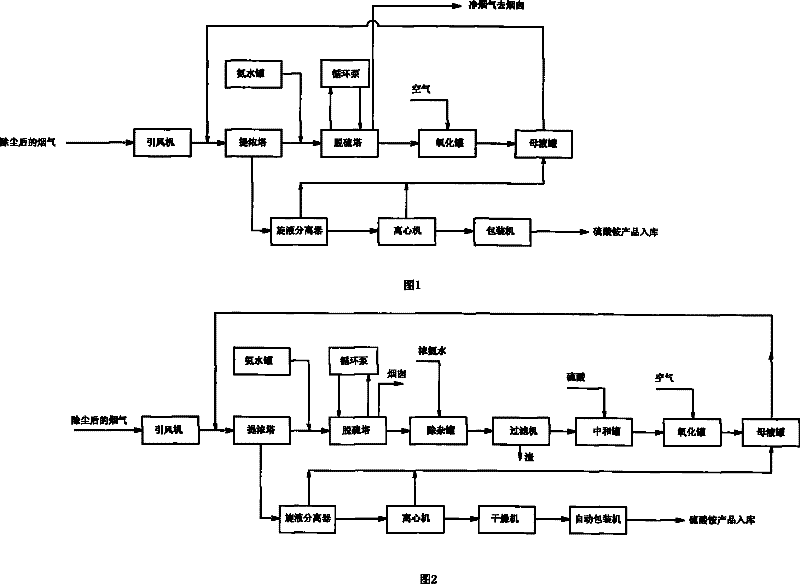

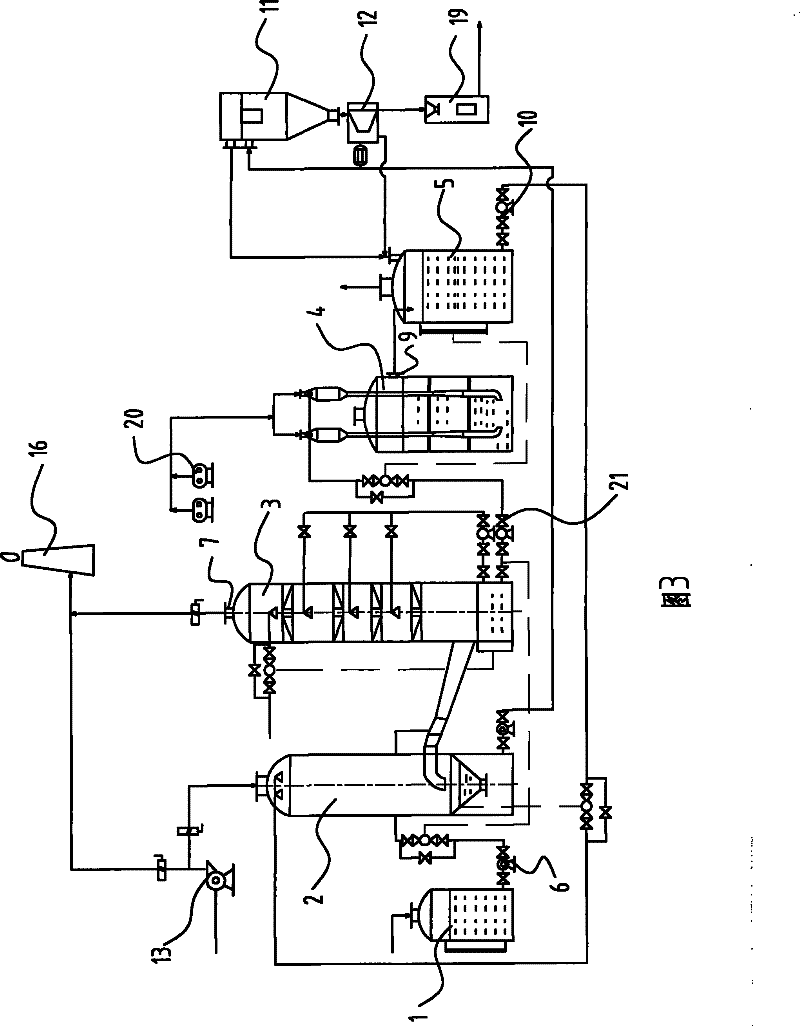

[0031] As shown in Figure 1, the high-efficiency wet ammonia recovery desulfurization method of the present embodiment is used to reclaim agricultural grade ammonium sulfate, including the following steps:

[0032] (1) After the flue gas from the boiler is dedusted by the dust collector, it enters the top of the concentration tower through the induced draft fan. After cooling and humidifying, the flue gas first enters the first-level Venturi section of the desulfurization absorption system, and the concentration after atomization is 5 % of ammonia water contacts and undergoes first-level absorption and reaction, and then enters the main desulfurization tower, through the circulating spray layer in the middle and upper part of the desulfurization tower, and the ammonium sulfite solution pumped by the desulfurization tower ammonium liquid pump is again atomized and fully contacted and absorbed. Second and third-stage desulfurization, the purified flue gas passes through the demis...

Embodiment 2

[0037] As shown in Figure 2, the high-efficiency wet ammonia recovery desulfurization method of the present embodiment is used to recover industrial-grade ammonium sulfate, including the following steps:

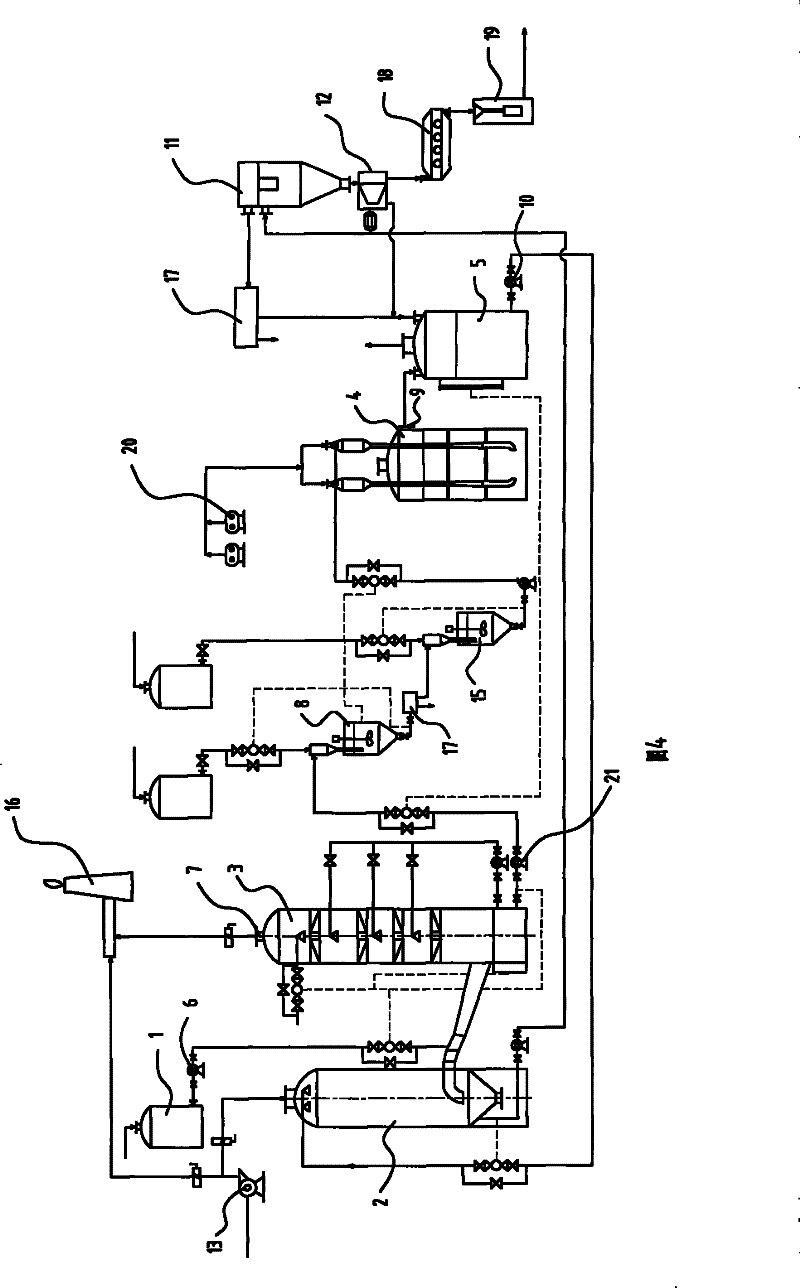

[0038] (1) After being dedusted by the electrostatic precipitator, the flue gas first enters the concentration tower, and after cooling and humidifying the concentration tower, it comes out from the lower part, and is atomized and contacted with the added dilute ammonia water with a concentration of 5% through the Venturi pre-desulfurization section Absorb SO in flue gas 2 , after secondary or tertiary desulfurization, ammonium sulfite solution is generated, and the net flue gas after desulfurization is discharged from the chimney;

[0039] (2) The ammonium sulfite solution generated is sent into the impurity removal tank through the ammonium liquid pump to remove impurities, then after filtering through the filter, the filter residue is discharged, and the filtrate enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com