Sulfonated polyarylether based on triphenylphosphine oxide structure unit and preparation method thereof

A technology of triphenylphosphine oxide and sulfonated polyarylether, which is applied in the field of sulfonated polyarylether based on triphenylphosphine oxide structural unit and its preparation, can solve the problems not involving sulfonated polyarylether, and achieve The synthesis method is simple, the thermal stability is good, and the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

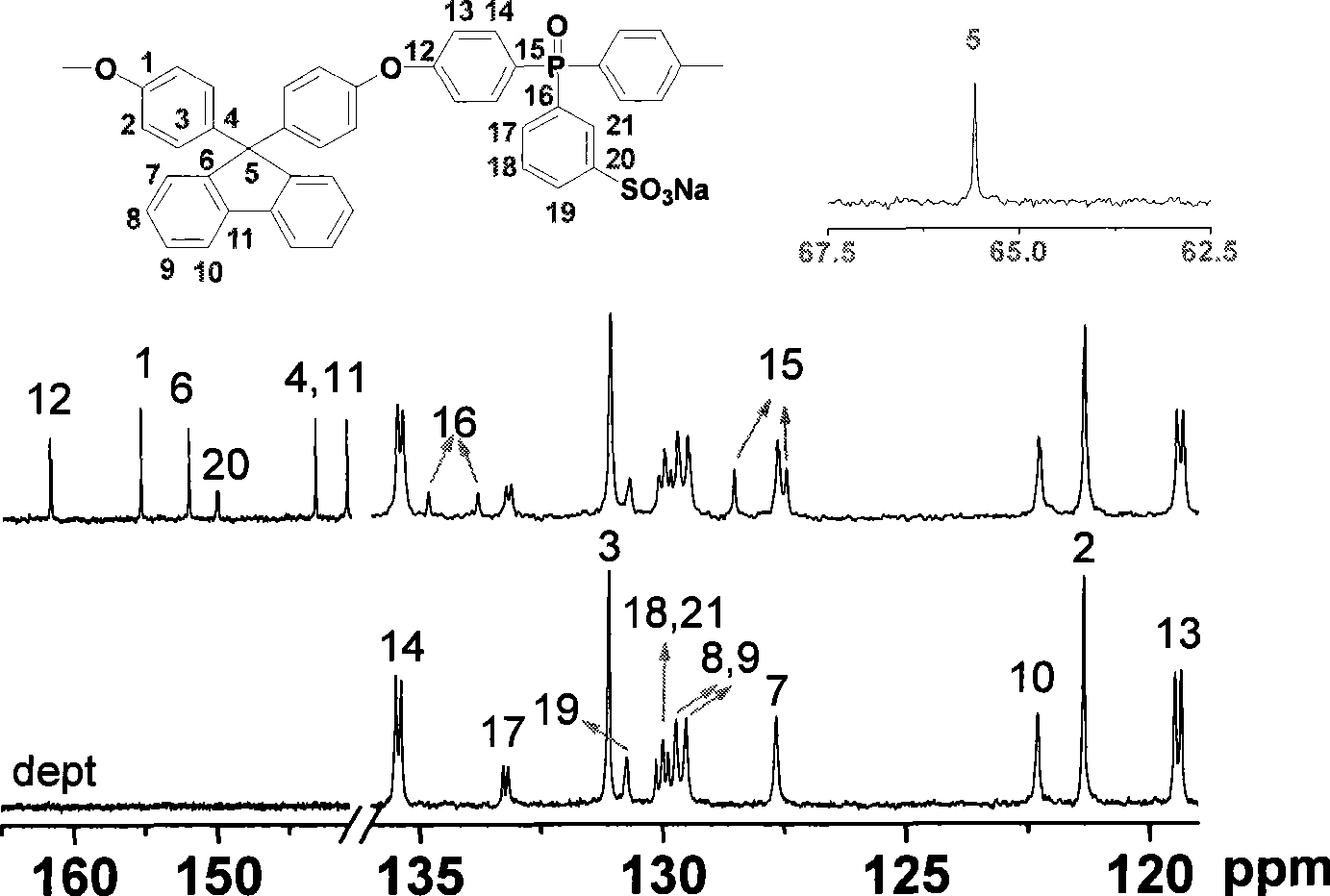

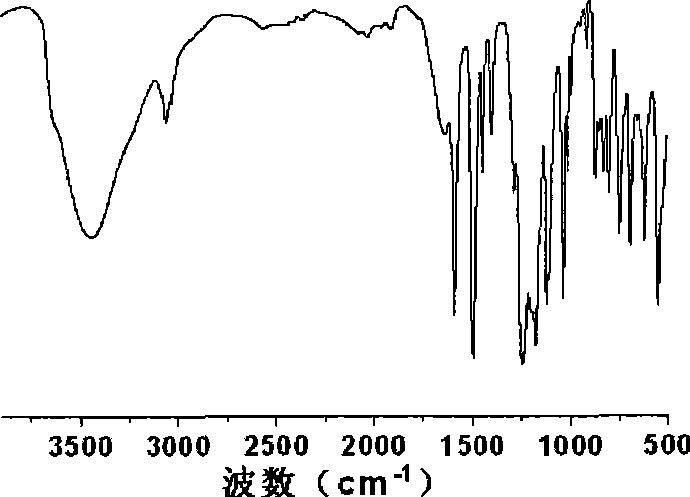

[0038] Example 1: 3.0mmol bis(4-fluorophenyl)-3'-sulfonate sodium phenylphosphine oxide, 3.0mmol 9,9-bis(4-hydroxyphenyl)fluorene, 3.3mmol cesium carbonate, 8mL1- Methyl-2-pyrrolidone and 9 mL of toluene were added to a three-neck flask equipped with a stirrer, a water separator and a condenser. Under the protection of nitrogen, the temperature was raised to 160°C, and after azeotropic dehydration for 4 hours, the azeotropic dehydrating agent toluene was discharged, the temperature was raised to 175°C, and the reaction was carried out for 60 hours. After natural cooling, precipitate in ethanol and water, desalt after filtration, and vacuum dry at 100°C for 24 hours to obtain sulfonated polyarylether containing triphenylphosphine oxide structural unit.

[0039] The yield of the reaction is 96%, the temperature of 5% thermal weight loss of the product is 385 DEG C, and no glass transition occurs in the range of 100-350 DEG C. The intrinsic viscosity at 30°C was 1.17 dL / g. figu...

Embodiment 2

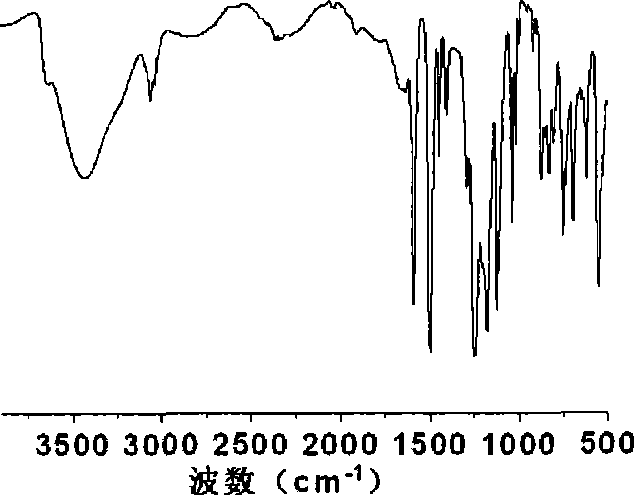

[0040] Example 2: 1.8mmol bis(4-fluorophenyl)-3'-sulfonate sodium phenylphosphine oxide, 1.2mmol bis(4-fluorophenyl)phenylphosphine oxide, 3.0mmol9,9-bis(4 -Hydroxyphenyl)fluorene, 3.3 mmol of cesium carbonate, 8 mL of 1-methyl-2-pyrrolidone and 9 mL of toluene were added to a three-neck flask equipped with a stirrer, a water separator and a condenser. Under nitrogen protection, the temperature was raised to 150°C, and after azeotropic dehydration for 3 hours, the azeotropic dehydrating agent toluene was discharged, the temperature was raised to 190°C, and the reaction was carried out for 48 hours. After natural cooling, it precipitates in water, desalts after filtration, and vacuum-dries at 100°C for 24 hours to obtain sulfonated polyarylene ether containing triphenylphosphine oxide structural unit.

[0041] The yield of the reaction is 95%, the temperature of 5% thermal weight loss of the product is 411 DEG C, and no glass transition occurs in the range of 100-350 DEG C. Th...

Embodiment 3

[0042]Example 3: 2.7mmol bis(4-fluorophenyl)-3'-sulfonate sodium phenylphosphine oxide, 0.3mmol bis(4-fluorophenyl)phenylphosphine oxide, 3.0mmol 2,2-bis- (4-Hydroxyphenyl)hexafluoropropane, 3.3 mmol of potassium carbonate, 8 mL of 1-methyl-2-pyrrolidone and 8 mL of toluene were added to a three-neck flask equipped with a stirrer, a water separator and a condenser. Under the protection of nitrogen, the temperature was raised to 150°C, and after azeotropic dehydration for 4 hours, the azeotropic dehydrating agent toluene was discharged, the temperature was raised to 185°C, and the reaction was carried out for 80 hours. After natural cooling, it precipitates in water, desalts after filtration, and vacuum-dries at 100°C for 24 hours to obtain sulfonated polyarylene ether containing triphenylphosphine oxide structural unit.

[0043] The yield of the reaction is 96%, the temperature of 5% thermal weight loss of the product is 440°C, and the glass transition temperature is 380°C. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com