Liquid milk containing soya peptide and production method thereof

A technology for dairy products and soybean peptides, applied in the directions of milk preparations, dairy products, food preparation, etc., can solve the problem that the acceptance of food flavor is reduced, the soybean peptide powder cannot be completely dissolved, and the beany and bitter taste of soybean peptide powder cannot be completely eliminated. and other problems to achieve the effect of improving human function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1. Neutral milk drink containing soybean peptide and its production method

[0039] One, prepare the neutral milk drink of the present embodiment according to the following raw material weight ratios:

[0040] Milk 500‰, white sugar 40‰, soybean peptide powder (purchased from Linyi Shansong Biological Products Co., Ltd., dry base peptide content ≥ 80%, molecular weight distribution range 800-2300Da) 5‰, glyceryl monostearate 1‰ , propylene glycol fatty acid ester 0.3‰, xanthan gum 0.25‰, locust bean gum 0.15‰, sodium tripolyphosphate 0.3‰, food flavor 0.1‰, water balance.

[0041] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0042] Two, the production method of the neutral milk drink of the present embodiment is carried out according to the following steps:

[0043] 1. Milk inspection: It is required that the fat, protein, dry matter and other indicators meet the quality standards of raw milk, and re...

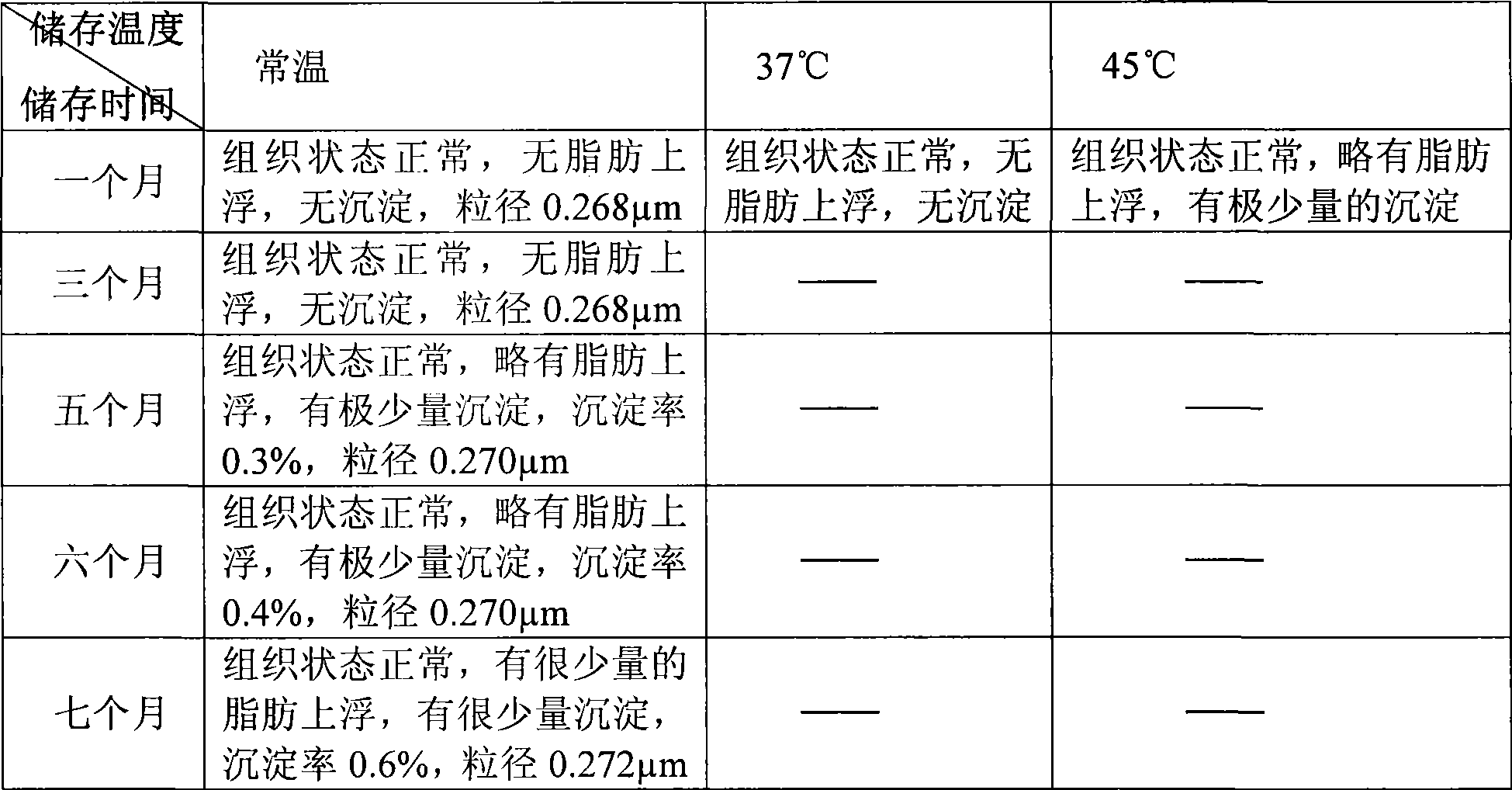

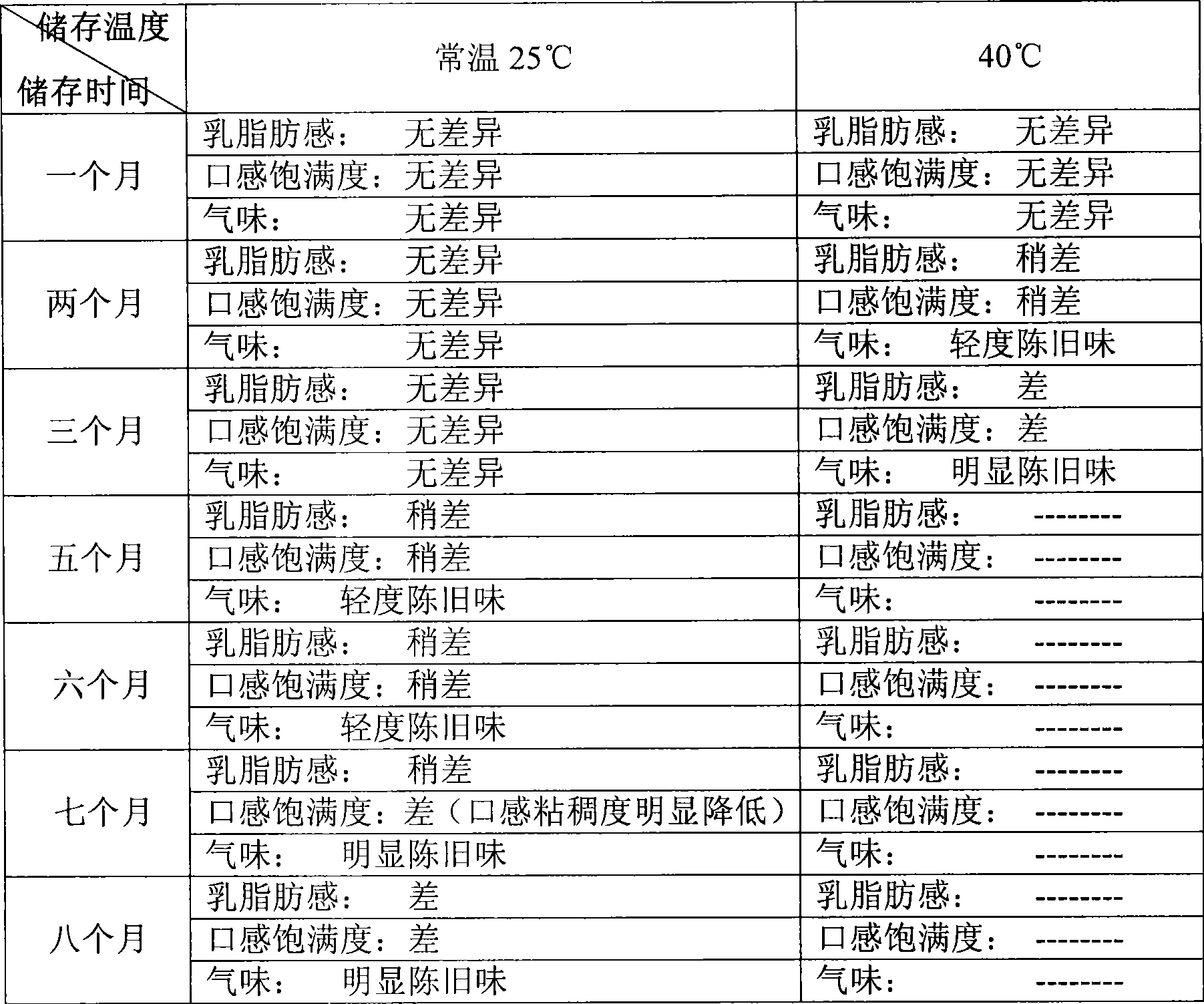

Embodiment 2

[0060] Embodiment 2. Neutral flavored milk containing soybean peptide and production method thereof

[0061] One, prepare the neutral flavored milk of the present embodiment according to the following raw material weight ratios:

[0062] Milk 800‰, glucose 40‰, fructose 10‰, soybean peptide powder (purchased from Linyi Shansong Biological Products Co., Ltd., dry base peptide content ≥ 80%, molecular weight distribution 800-2300Da) 6.0‰, polyglycerol monostearate Ester 0.5‰, calcium stearoyl lactylate 0.2‰, microcrystalline cellulose 0.05‰, sodium alginate 0.3‰, sodium hexametaphosphate 0.2‰, food flavor 0.1‰, water balance.

[0063] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0064] Two, the production method of the neutral flavored milk of the present embodiment is carried out according to the following steps:

[0065] Pour an appropriate amount of milk into the chemical tank, heat it to 60-70°C, and then add mixed ...

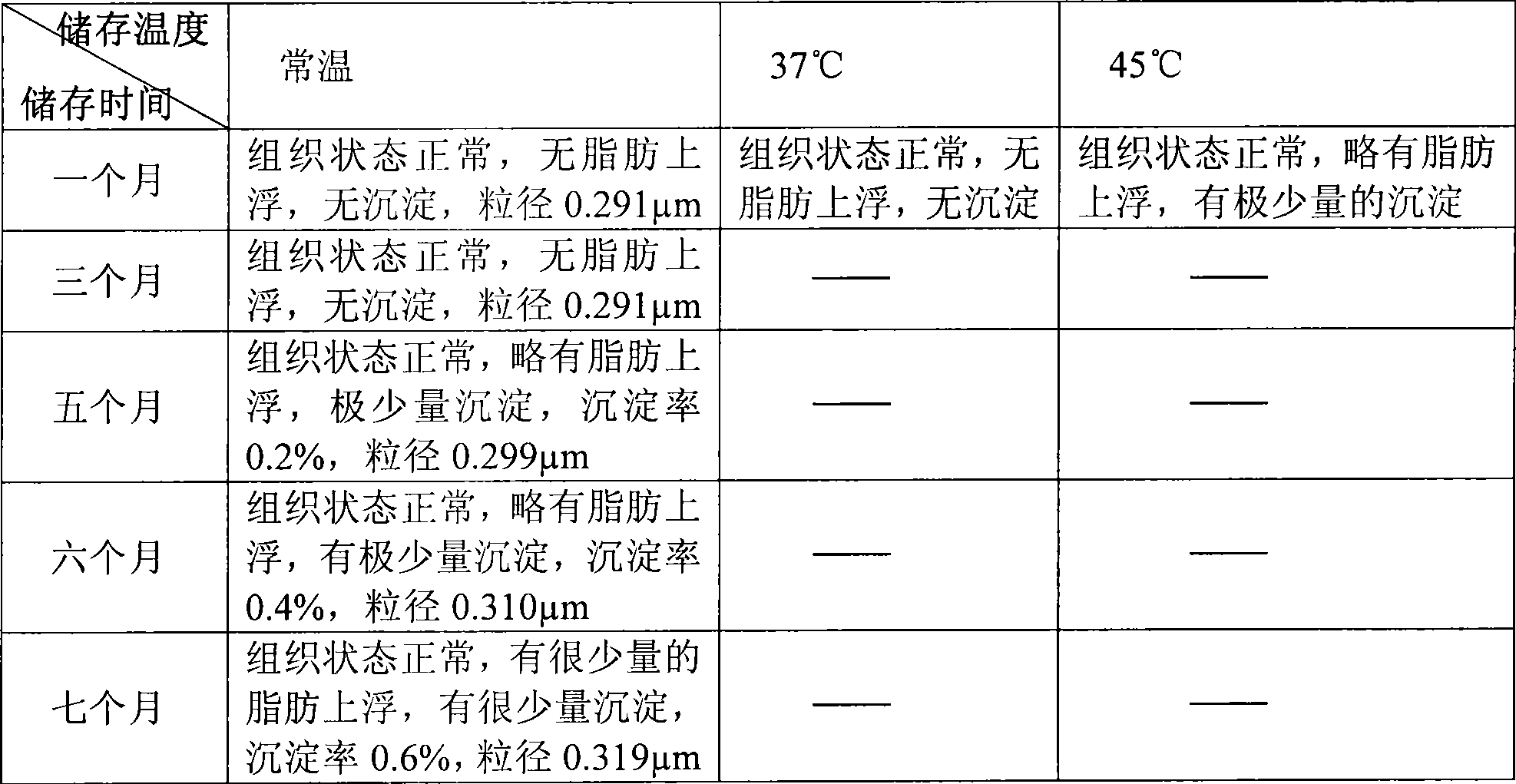

Embodiment 3

[0080] Embodiment 3. Whole-fat sterilized milk containing soybean peptide and its production method

[0081] One, prepare the full-fat sterilized milk of the present embodiment according to the following raw material weight ratios:

[0082] Whole milk 989.55‰, soybean peptide powder (purchased from Linyi Shansong Biological Products Co., Ltd., dry base peptide content 84.9%, molecular weight distribution 800-2300Da) 8‰, sodium stearoyl lactylate 1.0‰, sodium alginate 1.0‰, Carrageenan 0.15‰, sodium tripolyphosphate 0.3‰.

[0083] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0084] Two, the production method of the full-fat sterilized milk of the present embodiment is carried out according to the following steps:

[0085] 1. Milk inspection: It is required that the fat, protein, dry matter and other indicators meet the quality standards of raw milk, and refrigerated below 4°C.

[0086] 2. Ingredients: Pour an appropri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com