Method for preparing indissoluble aquatic collagen protein source ACE inhibitor peptides

A technology of aquatic collagen and collagen, which is applied to the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of complex process, low product efficiency, high production cost, etc., and achieve simple production process, increase productivity, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

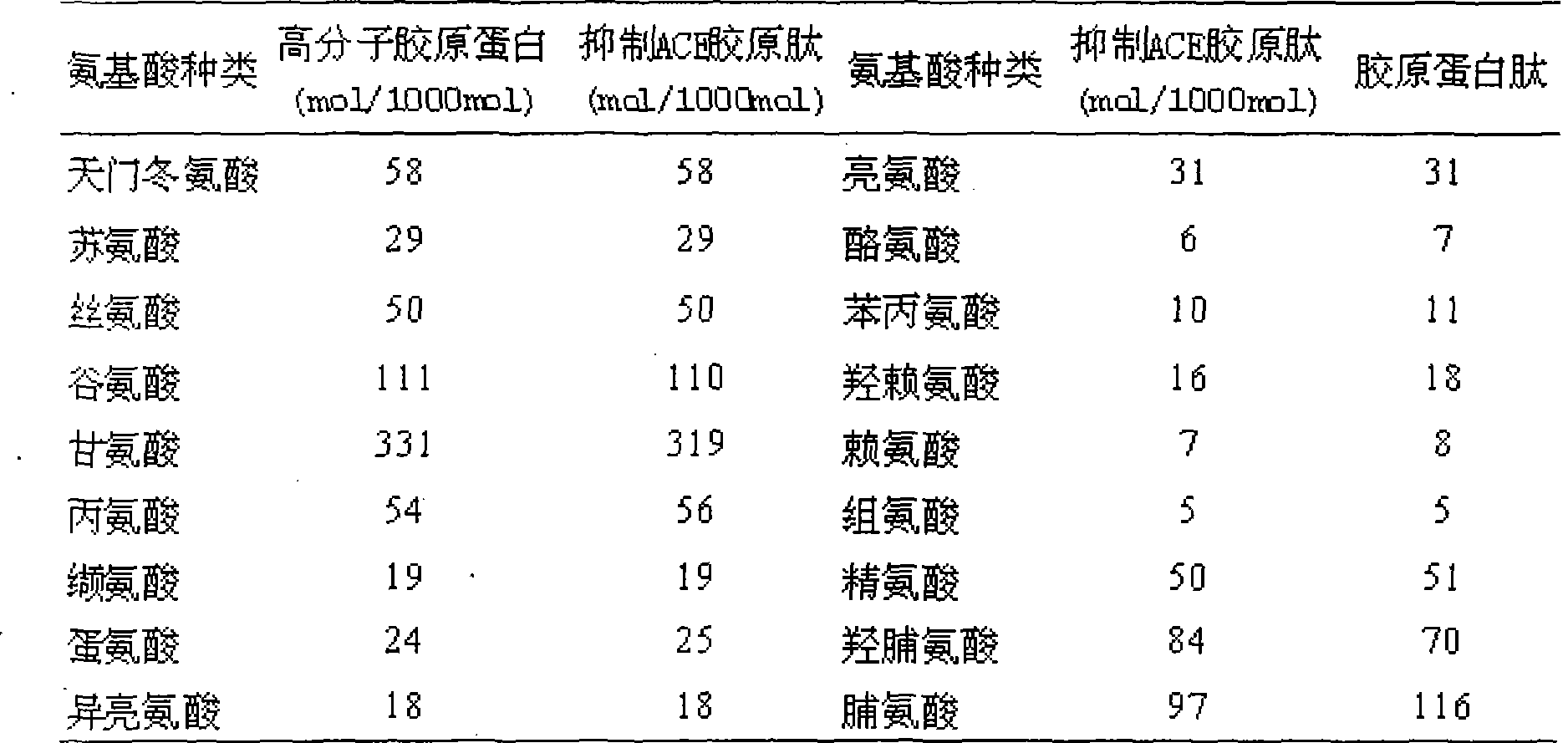

Method used

Image

Examples

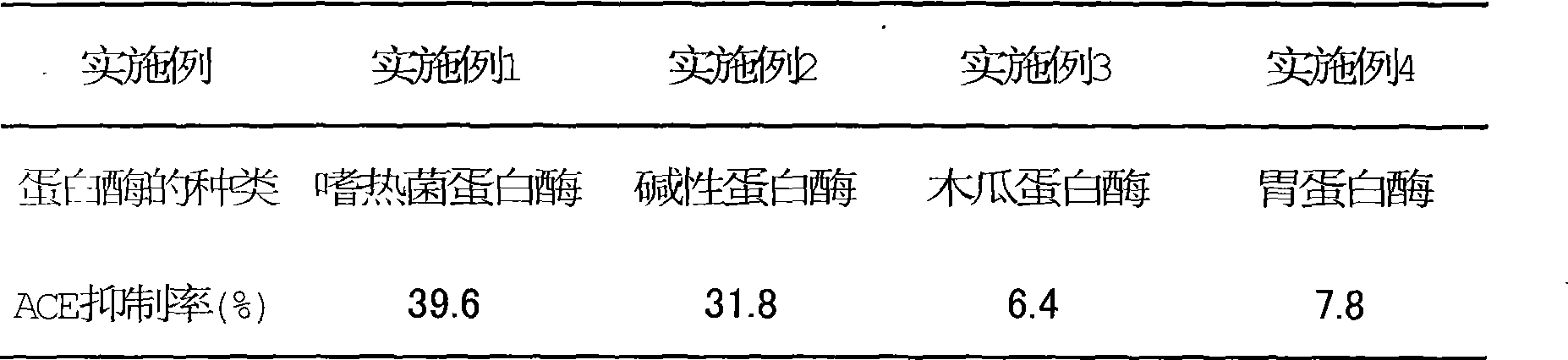

Embodiment 1

[0040] Take 100g of cleaned fresh scallop mantle, cut it into 1cm×1cm pieces at a temperature of 4°C, put the cut pieces into 500ml distilled water, and grind them into a pulp at a temperature of 4°C. And put into the high-speed centrifuge with the rotating speed of 10000rpm high-speed centrifugation 10min to remove the impurities such as part fat and pigment, obtain precipitate; Take the caustic soda solution that the equivalent concentration is 0.1N, the precipitate obtained is added in this caustic soda solution, Control the mass ratio of caustic soda solution to sediment to 20:1, place it in an environment with a temperature of 4°C, stir for 12 hours, then centrifuge at a speed of 5000rpm to remove the supernatant; wash the precipitate with distilled water 3 times, After each cleaning, remove the upper cleaning solution by high-speed centrifugation to obtain the sediment raw material; respectively take acetic acid solution and pepsin (pig stomach source, EC 3.4.23.1) with a...

Embodiment 2

[0042] Take 100g of cleaned fresh scallop mantle, cut into 1cm×1cm pieces at a temperature of 2°C, put the cut pieces into 800ml distilled water, and grind them into pulp at a temperature of 2°C. And put into the high-speed centrifuge with the rotating speed of 5000rpm high-speed centrifugation 30min to remove impurities such as part of fat and pigment, obtain precipitate; Get the caustic soda solution that the equivalent concentration is 0.1N, the precipitate obtained is added in this caustic soda solution, Control the mass ratio of the caustic soda solution to the precipitate to be 15:1, place it in an environment with a temperature of 2°C, stir for 48 hours, then centrifuge at a speed of 10,000 rpm to remove the supernatant; wash the precipitate with distilled water for 3 times, After each cleaning, remove the upper cleaning solution by high-speed centrifugation to obtain the raw material of the precipitate; respectively take citric acid solution and pepsin (pig stomach sour...

Embodiment 3

[0044] Get cleaned fresh scallop mantle 100g, under the condition of 3 DEG C, cut into pieces of 1cm * 1cm, put the cut pieces into 650ml distilled water, under the condition of 3 DEG C, mince them into pulp, And put into the high-speed centrifuge with the rotating speed of 7500rpm high-speed centrifugation 20min to remove impurities such as part of fat and pigment, obtain precipitate; Get equivalent concentration and be the caustic soda solution of 0.1N, add the precipitate obtained in this caustic soda solution, Control the mass ratio of the caustic soda solution to the precipitate to be 18:1, place it in an environment with a temperature of 3°C, stir for 30 hours, then centrifuge at a speed of 7500rpm to remove the supernatant; wash the precipitate with distilled water 3 times, After each cleaning, the upper cleaning solution was removed by high-speed centrifugation to obtain the sediment raw material; the oxalic acid solution and acid protease (Aspergillus niger) with a mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com