Quinoline zinc luminescent material and electroluminescent devices including the same

A technology of electroluminescent devices and luminescent materials, applied in luminescent materials, electric solid devices, electrical components, etc., can solve the problems of affecting the light emission of guest dyes, poor stability of luminescent color to voltage, complex preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

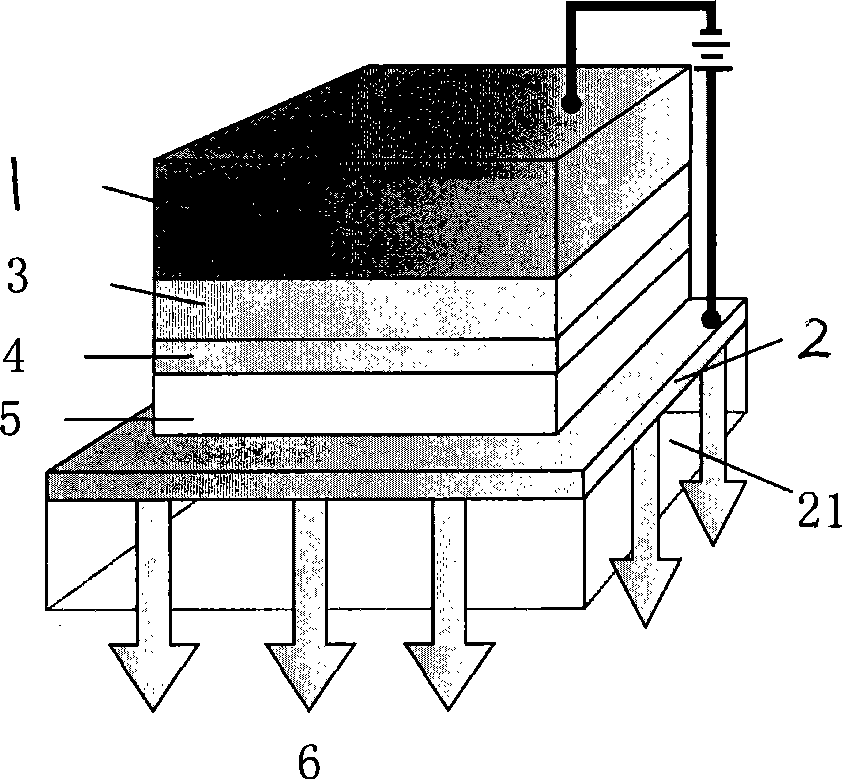

preparation example Construction

[0104] The preparation method of the composite luminescent material is not particularly limited, as long as the yellow luminescent material layer, the optional hole blocking layer, and the blue luminescent material layer each form a layered structure. The preparation method includes vapor deposition method, spin coating method and the like.

[0105] In the vapor deposition method, the composite luminescent material is obtained by a method comprising the following steps: respectively adopting a vacuum thermal evaporation method to sequentially vapor-deposit to form a yellow luminescent material layer, and optionally the hole blocking layer , and the blue luminescent material layer, thereby obtaining the composite material;

[0106] Preferably, during the evaporation film formation process, the vacuum degree is not lower than 2×10 -3 Pa, the evaporation current is 10.0-12.5A, and the specific evaporation rate is controlled between 0.2-0.3nm / s.

Embodiment 1

[0142] Experimental Methods and Test Methods

[0143] Experimental method and test method of the present invention are as follows:

[0144] The vacuum thermal evaporation film forming method involved in the present invention adopts the DM-220 high vacuum multi-stage coating machine of Shanghai Tianjing Electronic Optical Technology Co., Ltd.

[0145] The measurement of the vacuum degree adopts the ZDF-2F compound vacuum gauge of Shanghai Jinma Electro-optical Technology Research Institute.

[0146] The thickness of the film is monitored by the LHC-2 film thickness monitor of Shanghai Jinma Electro-optical Technology Research Institute.

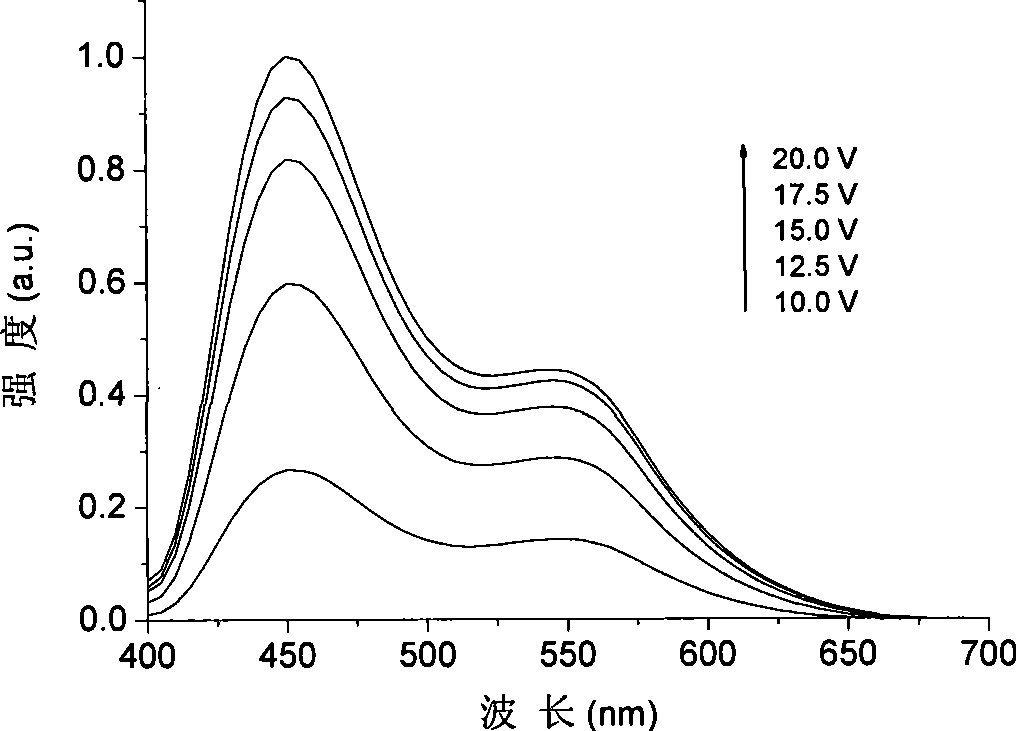

[0147] Organic luminescent material Zn(Q-4-biPh) 2 The characterization and the electroluminescent performance of the white light organic electroluminescent device device are tested as follows by the following method:

[0148] 1. Structural characterization

[0149] use 1 H NMR, MS and UV-Vis for ligand HQ-4-biPh and organic light-emittin...

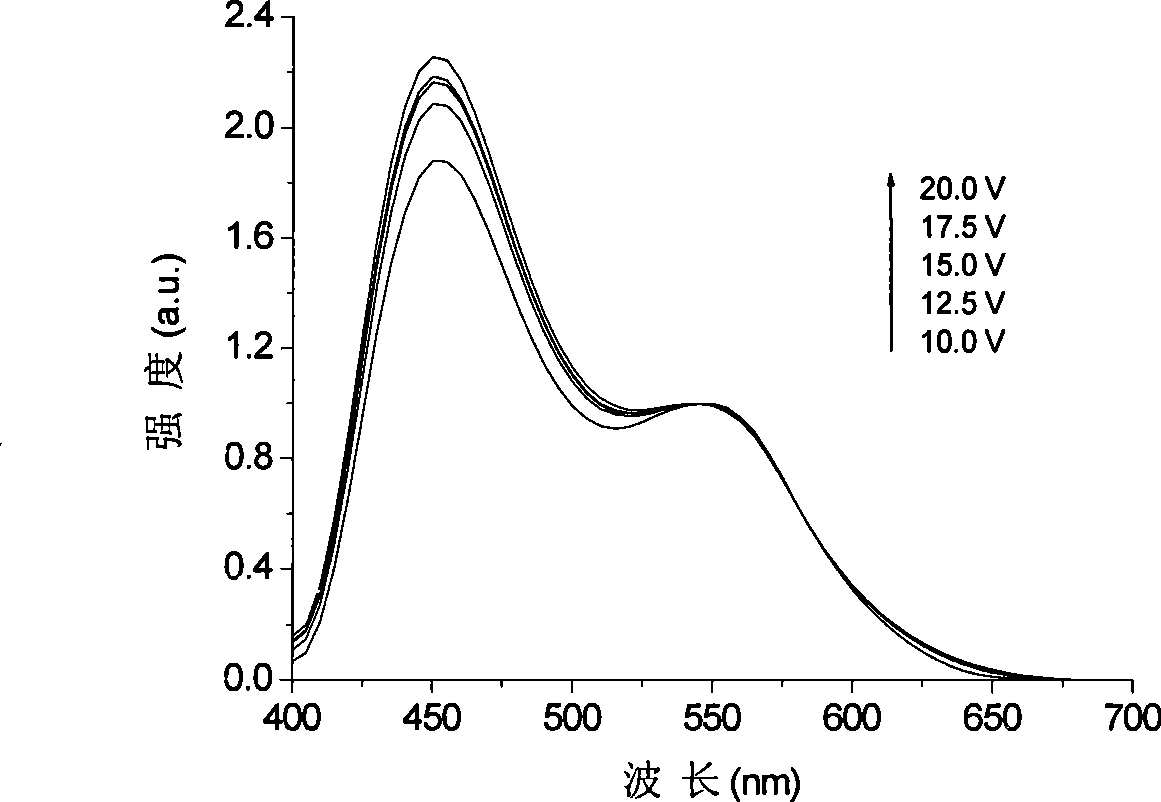

Embodiment 2

[0172] Example 2 uses the same method as Example 1, except that 2-bromobiphenyl is used as a raw material to prepare the organolithium reagent.

[0173] The experimental results are as follows:

[0174] The 2-o-biphenyl-8-hydroxyquinoline (HQ-2-biPh) productive rate that the 1st step obtains is 57%, records experimental data as follows:

[0175] 2-o-biphenyl-8-hydroxyquinoline (HQ-2-biPh)

[0176] m.p.108~110℃;

[0177] UV-vis (CHCl 3 )λ max : 268, 319nm;

[0178] 1 H NMR (CDCl 3 , 500MHz) δ: 8.1 (br.s, 1H, -0H), 7.9 (m, 2H, Ar-H), 7.6 (m, 3H, Ar-H), 7.5 (m, 1H, Ar-H), 7.2~7.3(m, 4H, Ar-H), 7.1~7.2(m, 4H, Ar-H);

[0179] MS m / z (%): 298 (M + , 100), 139(21), 63(22), 51(39).

[0180] The 2-o-biphenyl-8-hydroxyquinoline zinc (Zn(Q-2-biPh) obtained in the 2nd step 2 ), productive rate is 55%, and test data is as follows:

[0181] m.p.281~282℃;

[0182] UV-vis (CHCl 3 )λ max : 290, 410nm;

[0183] FL (thin film): 561nm (λ ex =430nm) MS m / z (%): 660 (M + , 32), 36...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com