Production method of refined trichlorosilane

A technology for refining trichlorosilane and trichlorosilane, which is applied in the production method of chemical products and the field of rectification separation and purification, can solve the problems of energy consumption, low separation efficiency, waste, etc., and achieve good economic and social benefits, Effects of improving distillation efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

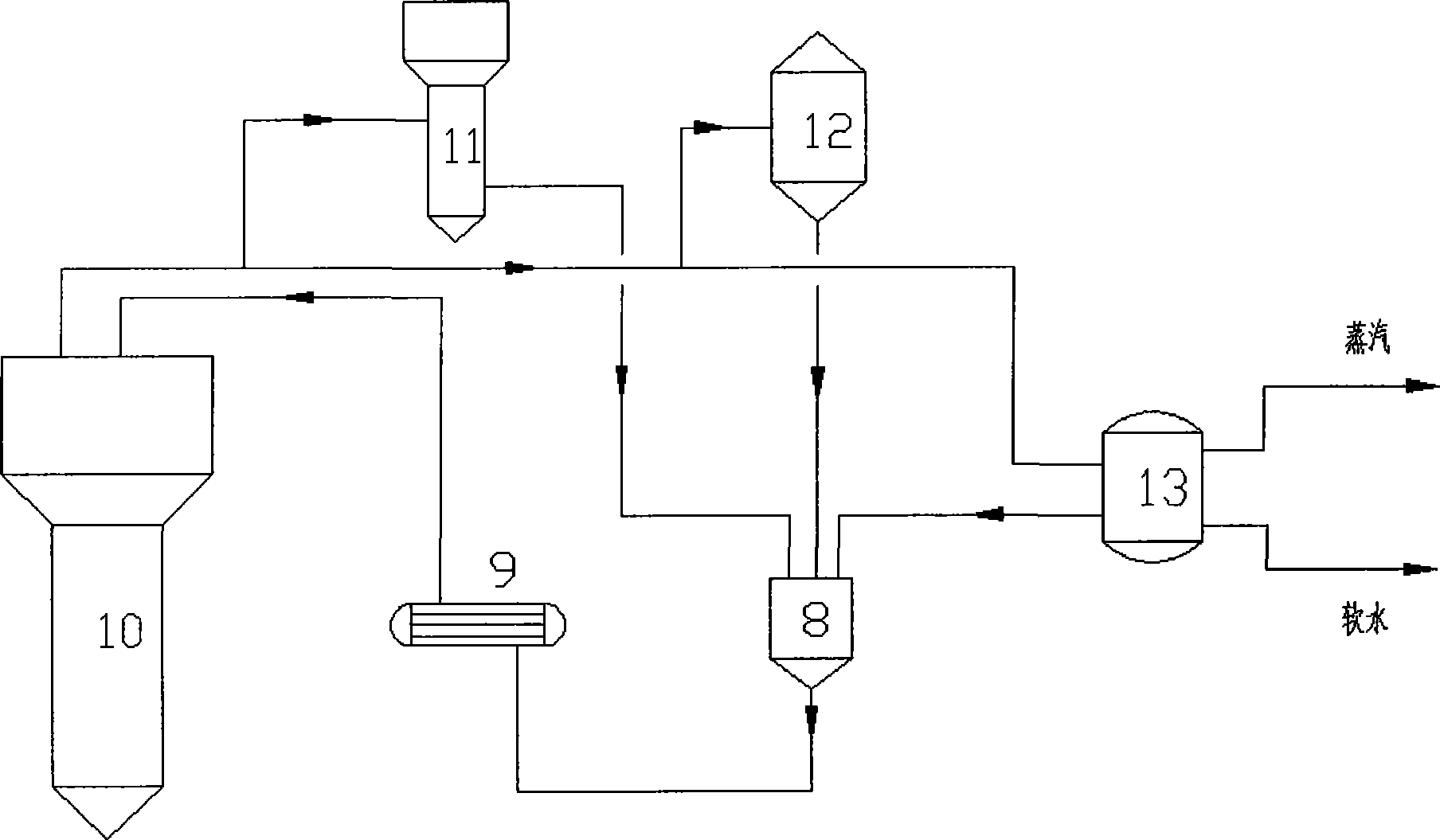

[0024] A production method of refined trichlorosilane. Hydrogen chloride and dried silicon powder are reacted in a synthesis furnace to form a mixture of trichlorosilane and silicon tetrachloride. The mixture is dust-removed to recover the remaining silicon powder, and then sent to the condensation system , the condensed chlorosilane mixture is sent to the rectification system to obtain industrial-grade trichlorosilane, and then through the refining and purification section to obtain high-purity refined trichlorosilane, whose characteristics are as follows:

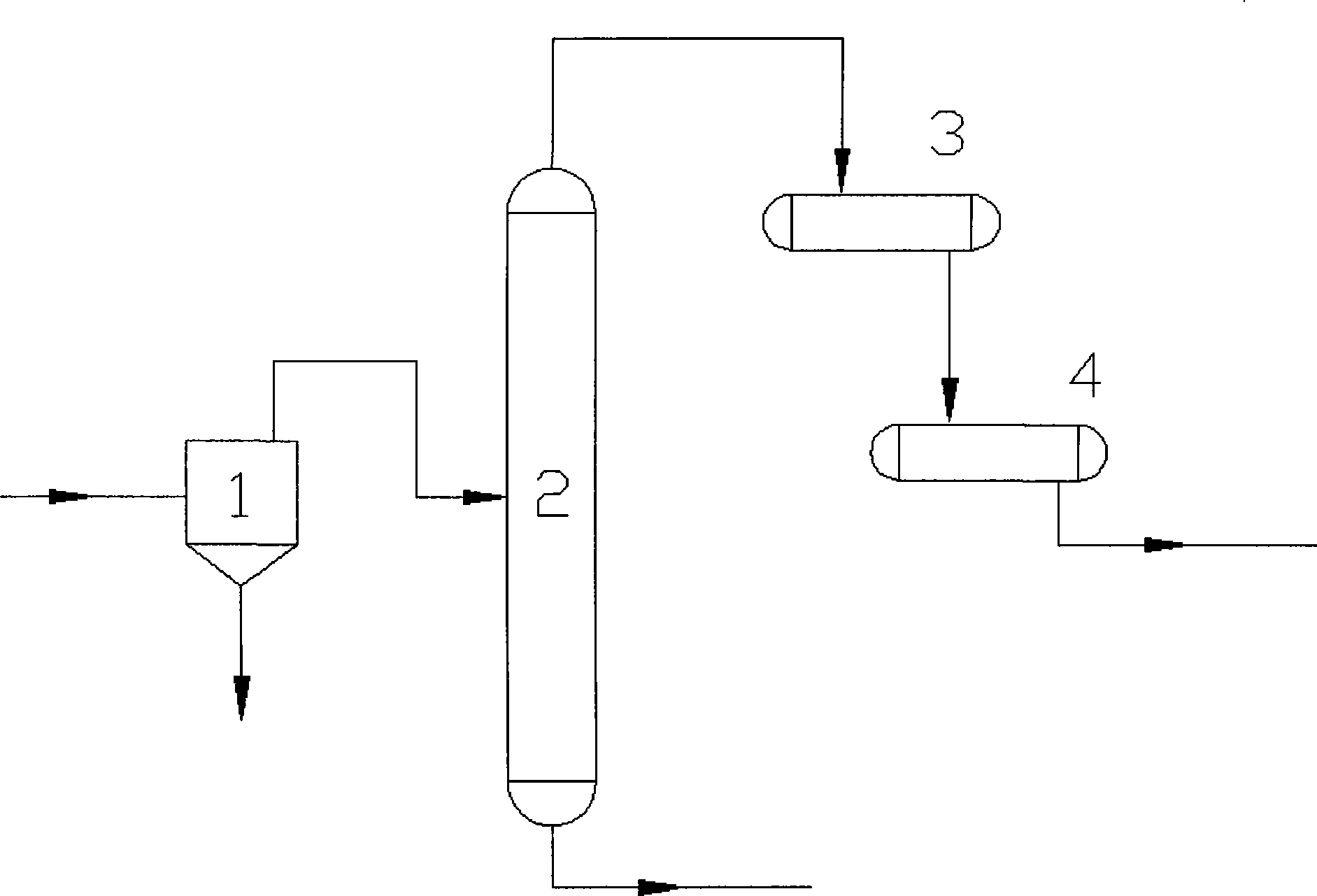

[0025] (1) To optimize the cooling process, increase the washing tower device: such as figure 1 , the mixture passes through the cyclone separator and the bag filter to recover the remaining silicon powder, and sends it to the washing tower to remove solids such as aluminum trichloride, and then enters the condensation system.

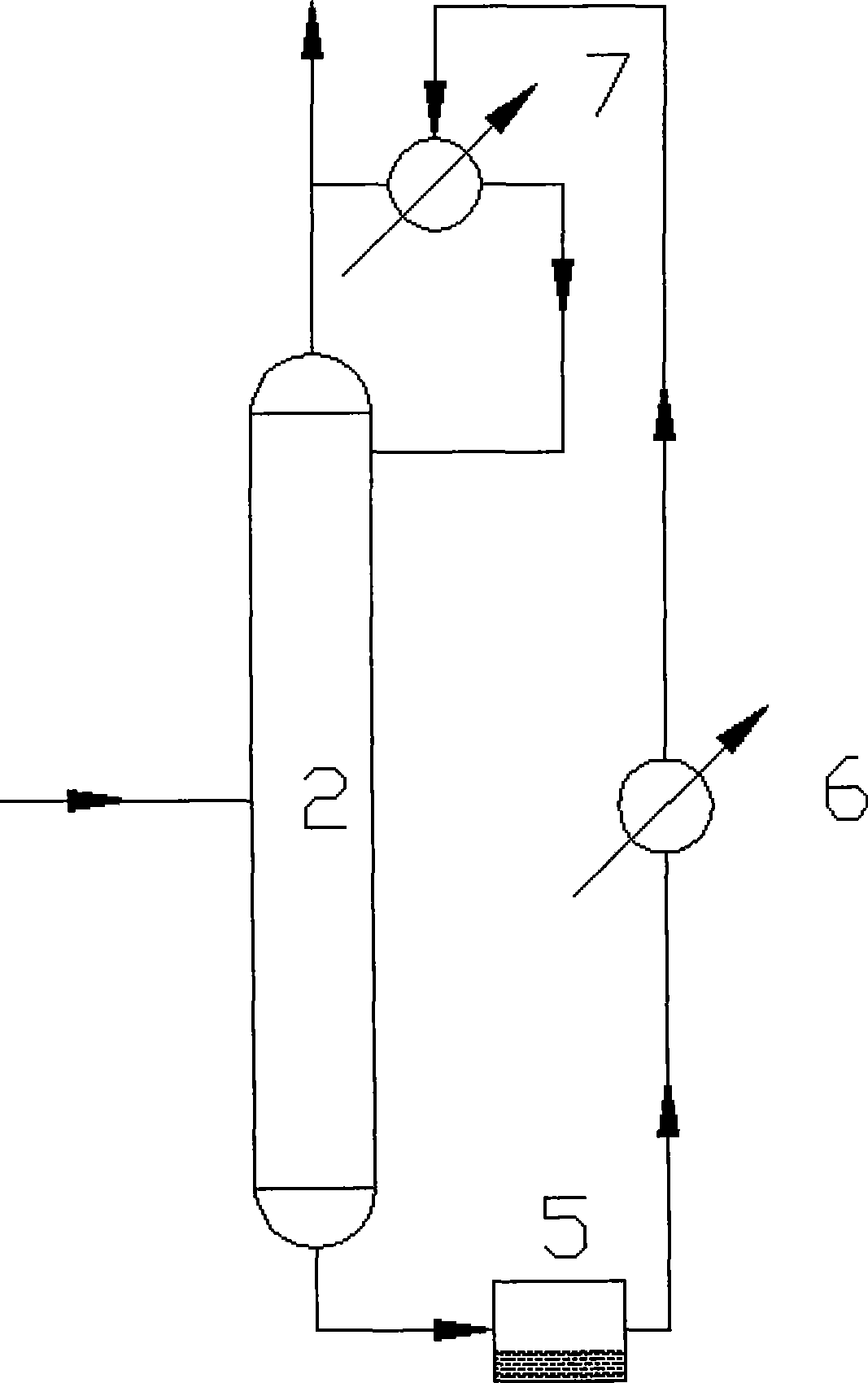

[0026] (2) Thermal integration and energy-saving utilization of synthetic heat: such as imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com