Boston butterhead lettuce water-culture nutrient solution and preparation method thereof

A hydroponic nutrient solution and nutrient solution technology, applied in the field of plant nutrition and fertilizer, to achieve the effect of sufficient raw materials, easy storage and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

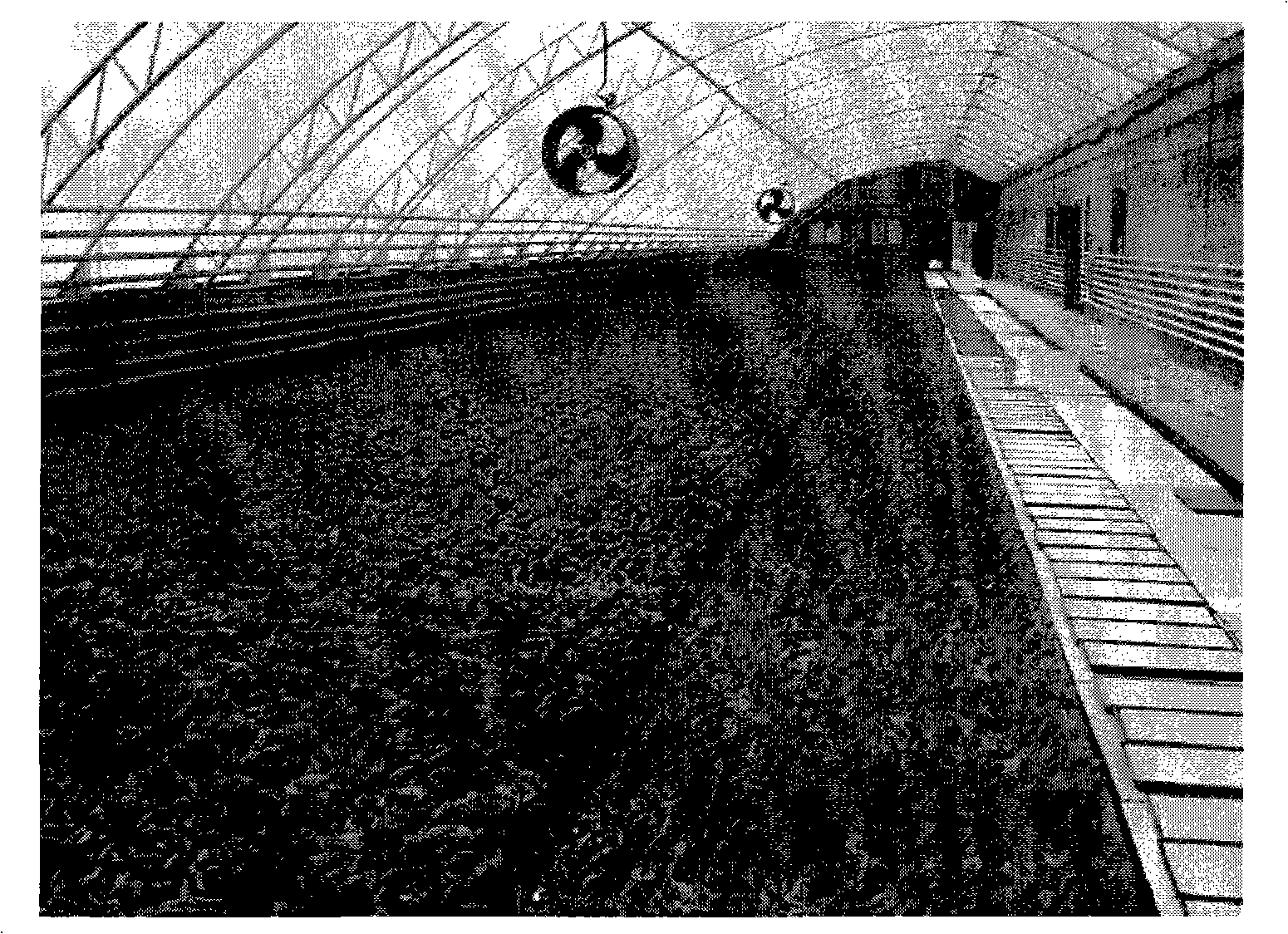

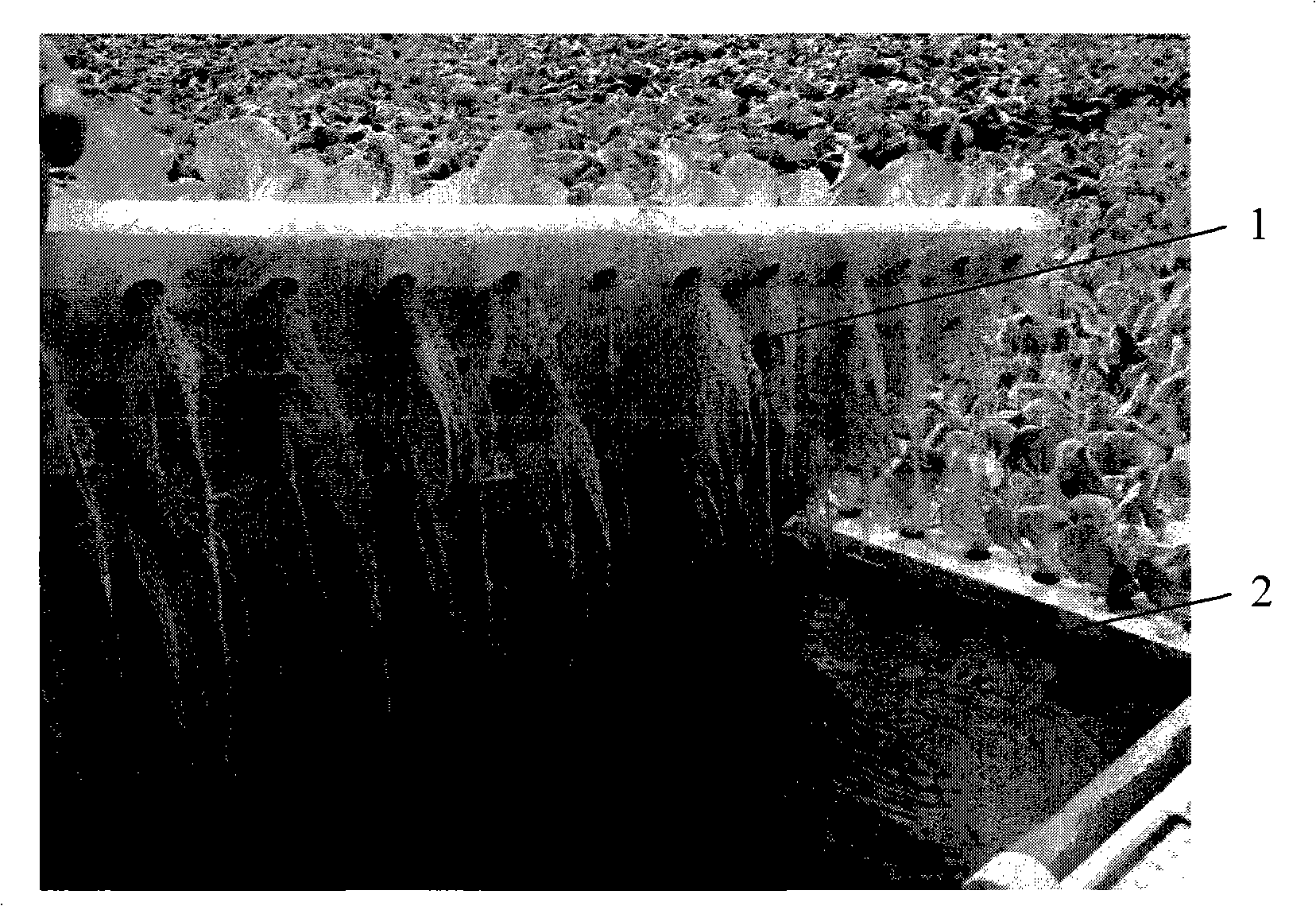

Image

Examples

Embodiment 1

[0042] 1) Dissolution of large and medium elements: take a 2000L plastic container, set the scale at 1000L in advance, put it into 700L of tap water, weigh and pour in 55kg of calcium nitrate tetrahydrate, 90kg of potassium nitrate, 6kg of ammonium nitrate, and magnesium sulfate heptahydrate 19kg, potassium sulfate 5.5kg, and sodium azide 0.25kg, stir with a plastic stick to mix the above drugs evenly, slowly add 25L of concentrated phosphoric acid at a speed of 5L / min, and stir evenly with a plastic stick to obtain large and medium element solutions.

[0043] 2) Dissolution of trace elements: Take a 100L plastic container, put in 55L of hot water at a temperature of 55°C, put in 1.5kg of iron ethylenediaminetetraacetate, 0.3kg of boric acid, 0.3kg of manganese sulfate tetrahydrate, heptahydrate 75g of zinc sulfate, 75g of copper sulfate pentahydrate, and 30g of ammonium molybdate tetrahydrate were stirred with a plastic rod to mix the above-mentioned medicines evenly. Cool to...

Embodiment 2

[0047] 1) Dissolution of large and medium elements: take a 1500L plastic container, set the scale at 1000L in advance, put it into 680L of tap water, weigh and pour in 60kg of calcium nitrate tetrahydrate, 80kg of potassium nitrate, 7kg of ammonium nitrate, and magnesium sulfate heptahydrate 20kg, potassium sulfate 6kg, sodium azide 0.3kg, stir with a plastic stick to mix the above drugs evenly, slowly add 25L of concentrated phosphoric acid at a speed of 5L / min, stir evenly with a plastic stick, and get large and medium element solutions.

[0048] 2) Dissolution of trace elements: Take a 100L plastic container, put in 60L of hot water at a temperature of 50°C, put in 1kg of iron ethylenediaminetetraacetate, 0.2kg of boric acid, 0.1kg of manganese sulfate tetrahydrate, sulfuric acid heptahydrate 50g of zinc, 100g of copper sulfate pentahydrate, and 40g of ammonium molybdate tetrahydrate were stirred with a plastic rod to mix the above-mentioned medicines evenly. Cool to obtain...

Embodiment 3

[0052] 1) Dissolution of large and medium elements: take a 1000L plastic container, set the scale at 1000L in advance, put it into 650L of tap water, weigh and pour in 50kg of calcium nitrate tetrahydrate, 100kg of potassium nitrate, 5kg of ammonium nitrate, and magnesium sulfate heptahydrate 18kg, potassium sulfate 5kg, and sodium azide 0.2kg, stir with a plastic stick to mix the above drugs evenly, slowly add 20L of concentrated phosphoric acid at a speed of 4L / min, and stir evenly with a plastic stick to obtain large and medium element solutions.

[0053] 2) Dissolution of trace elements: Take a 100L plastic container, put it into hot water at 50°C and 60°C, put in 2kg of iron ethylenediaminetetraacetate, 0.4kg of boric acid, 0.3kg of manganese sulfate tetrahydrate, and sulfuric acid heptahydrate 100g of zinc, 50g of copper sulfate pentahydrate, and 20g of ammonium molybdate tetrahydrate were stirred with a plastic rod to mix the above-mentioned medicines evenly. Cool to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com