Strengthened autotrophs desulphurization apparatus with complex function

An autotrophic, composite function technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low reactor processing capacity, limited membrane surface area, and low hydrogen solubility and other problems, to achieve the effect of strengthening sulfate reducing ability, improving bacterial adaptability, and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

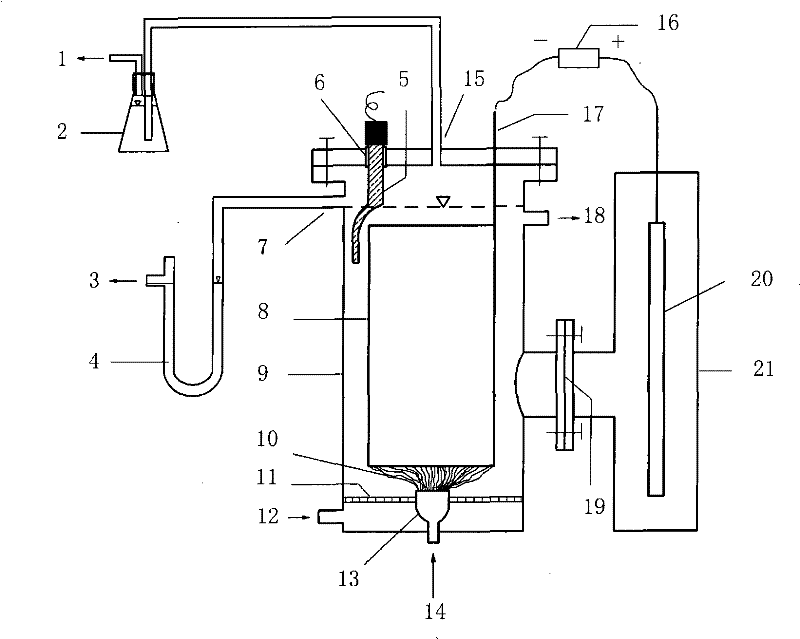

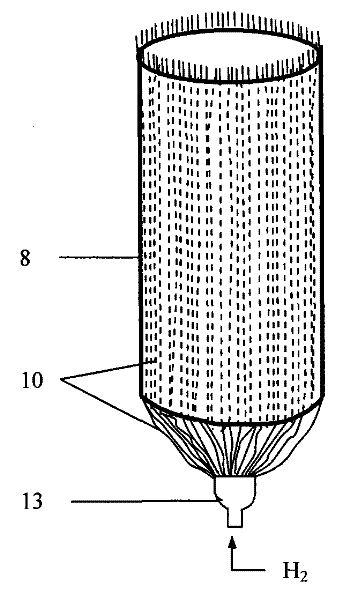

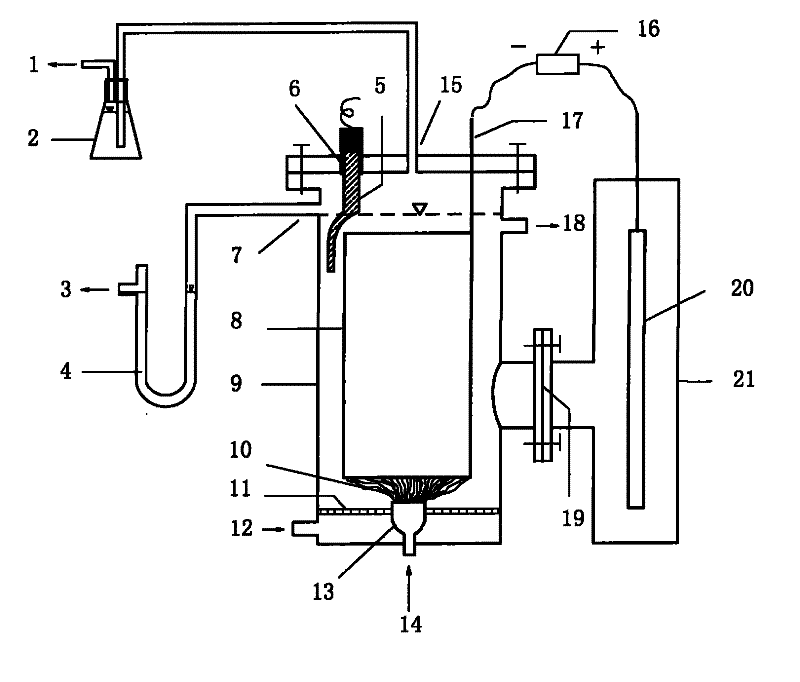

[0023] A device for strengthening autotrophic biological desulfurization with multiple functions, such as figure 1 As shown, the device is mainly composed of a cathode chamber 9 and an anode chamber 21. The cathode chamber 9 and the anode chamber 21 are separated by a proton membrane 19, and the shape-stable anode 20 is placed in the anode chamber 21 (the anode material is ruthenium-plated titanium). The cathode chamber 9 is mainly composed of a uniform water distributor 11 and a multifunctional three-dimensional composite biocathode, and the multifunctional three-dimensional composite biocathode (such as figure 2 shown) is mainly composed of a hydrogen supply system air intake chamber 13, a membrane wire 10, a conductive porous flexible carbon material 8 coated on the surface of the membrane wire (the carbon material is graphite felt), and fixed on one side of the flexible carbon material 8 to facilitate communication with the outside. Circuit-connected guide rods 17 (the gu...

Embodiment 2

[0028] The device of Example 1 was used to carry out self-distributing sulfate reduction. The hollow fiber membranes used were 300 polypropylene hollow fiber membranes (hydrophobic) produced by Tianjin Seawater Desalination Institute Blue Cross Membrane Technology Co., Ltd., with an effective length of 300mm. The conductive porous flexible carbon material adopts graphite felt (produced by Morgan Company) 300×150×5mm, and the specific surface area is 2000m 2 / g. Wrap the membrane filament inside the graphite felt and seal the end of the membrane filament. Roll the graphite felt coated with membrane wire into a cylindrical shape, sew it with non-conductive and corrosion-resistant materials such as nylon rope, and tightly bond it with graphite rods (25 × 6mm) to facilitate external circuit wiring. The cathode chamber adopts a cylindrical shape, the anode adopts a square shape, and the anode material is a porous mesh titanium electrode coated with ruthenium.

[0029] The power su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com