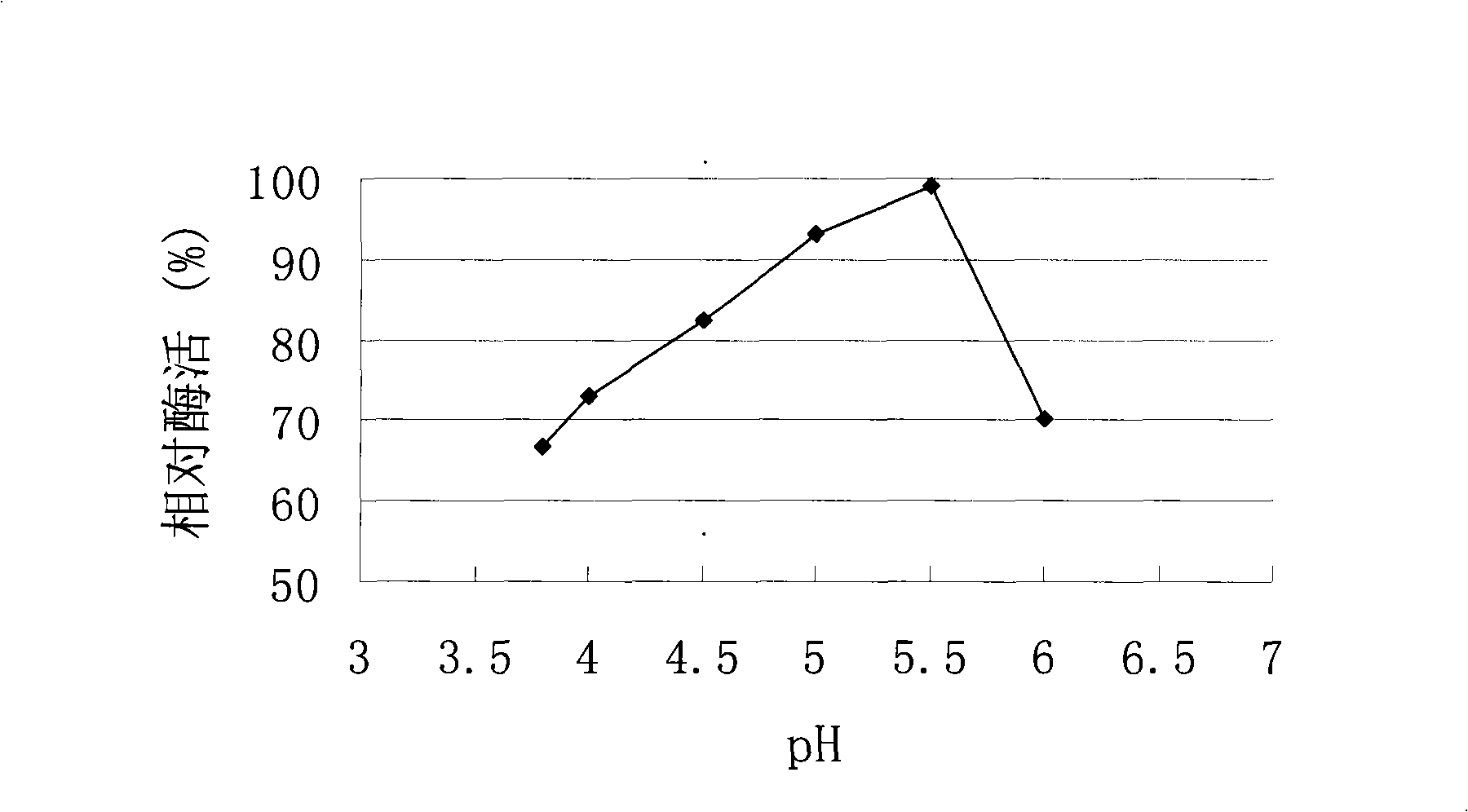

Acid-proof high-temperature amylase strain and method for producing acid-proof high-temperature amylase

A technology of high-temperature amylase and bacteria, applied in the field of bioengineering, can solve problems that have not been reported and achieve good acid-resistant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Slope formula (calculated in g / L): beef juice 4, peptone 10, yeast powder 3, NaCl3, starch 10, glucose 50, agar 15-25; culture temperature 35°C, culture time: 30h;

[0048] Shake bottle formula (calculated in g / L): bean cake powder 40, cottonseed cake powder 30, (NH 4 ) 2 SO 4 5. CaCl 2 0.5, corn steep liquor 30, lactose 150, sodium citrate 5, dipotassium hydrogen phosphate 15, potassium dihydrogen phosphate 7, culture temperature 40°C, culture time: 30h;

[0049] Seed tank formula (calculated in g / L): glucose 75, yeast powder 30, cottonseed cake powder 15, ammonium sulfate 5, sodium citrate 8, CaCl 2 0.5, P.P.E. (polyether defoamer) 0.5, dipotassium hydrogen phosphate 7, potassium dihydrogen phosphate 7, fermentation temperature: 35°C, ventilation: 0.8V.V.M, tank pressure: 0.8kg / cm 2 , Time: 36h, seed tank volume: 500L, 60% charge.

[0050] Production tank formula (calculated in g / L): glucose 75, yeast powder 30, cottonseed cake powder 15, ammonium sulfate 4, sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com