Combined treatment process for high-concentration organic waste water

A technology of organic waste water and treatment process, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, biological water/sewage treatment, etc. Low and other problems, to achieve the effect of wide application, low sludge output, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

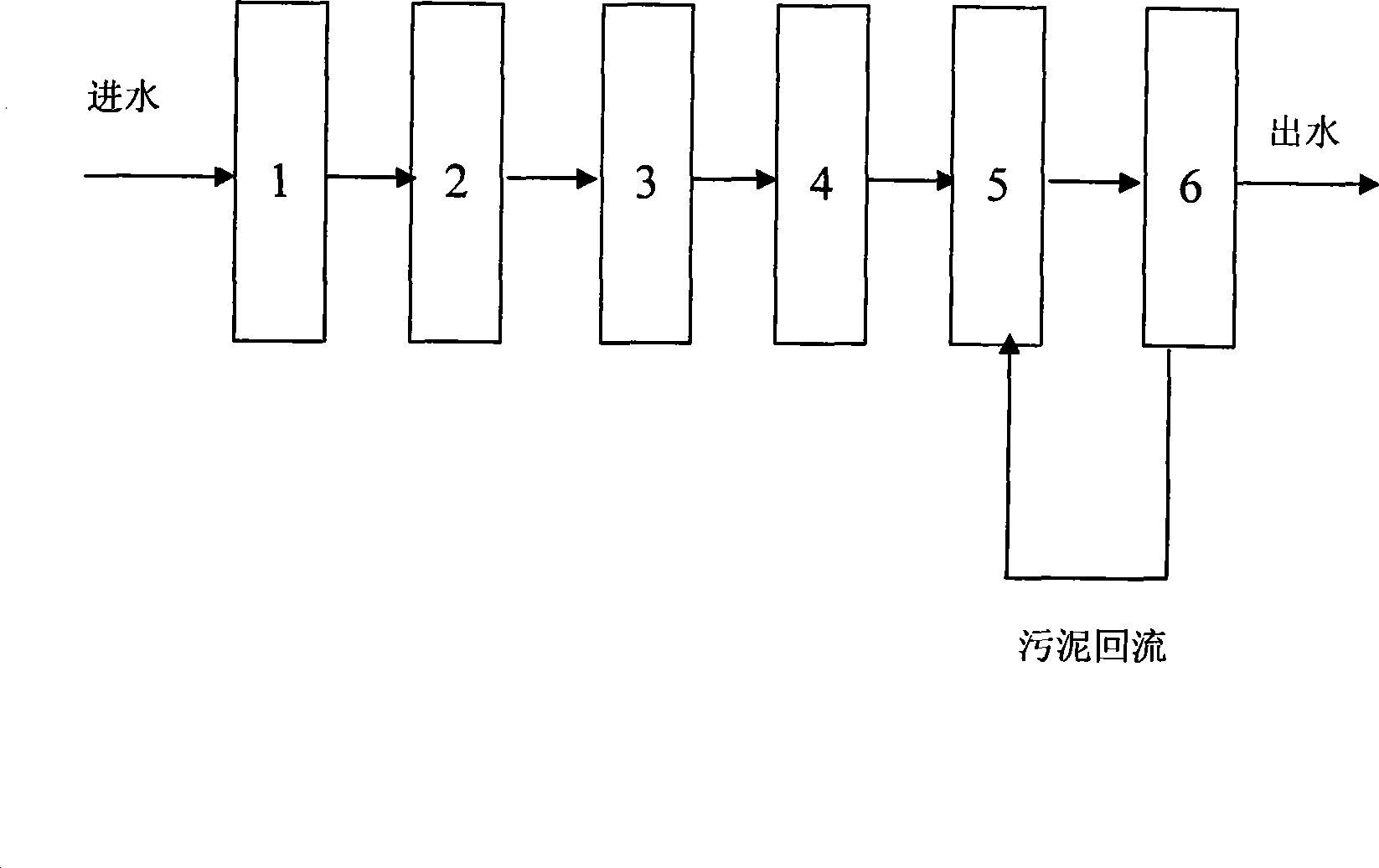

Image

Examples

Embodiment 1

[0022] A certain high-sulfur fermented industrial waste water, its water quality characteristics are as shown in table 1, the present invention inoculates micro-aerobic bacteria in the micro-aerobic reactor and carries out batch culture, when MLSS reaches 8g / L, directly pass into this undiluted The fermentation waste water starts to be treated continuously, the dissolved oxygen content in the reactor is controlled between 0-0.5 mg / L, and the hydraulic retention time is 3 days. 60-120 minutes, after ozone oxidation, the wastewater enters the activated sludge tank after passing through the intermediate tank. On the 12th day, 40% of the sludge was refluxed, and the effluent from the activated sludge tank was settled in the secondary settling tank to remove suspended solids and then discharged up to the standard. The water output indicators are shown in Table 1.

[0023] Table 1 The index values before and after a certain fermentation industrial wastewater is treated by the com...

Embodiment 2

[0026] The water quality characteristics of a certain food processing wastewater are shown in Table 2. First, microaerobic bacteria were inoculated in a microaerobic reactor and cultured in batches. When the MLSS reached 4g / L, the undiluted fermentation wastewater was directly introduced into Continuous treatment, control the dissolved oxygen content in the reactor between 0-0.5mg / L, the hydraulic retention time is 3d, the supernatant after the mixed solution is precipitated in the sedimentation tank enters the Fenton reagent oxidation reactor, according to the H 2 o 2 / COD(W / W)=4.0, Fe 2+ / H 2 o 2 Add Fe at a ratio of (W / W)=0.08 2+ and H 2 o 2 , after 130 minutes of reaction, it enters the intermediate tank, and the water from the intermediate tank (pH 7.5) enters the activated sludge tank. The residence time is 10 days, 20% of the sludge is refluxed, and the effluent from the activated sludge tank is settled in the secondary sedimentation tank to remove suspended solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com