Method for synthesizing molecular sieve membrane by dip coating-rubbing crystal-coating method

A molecular sieve and rolling rubbing technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as being unsuitable for industrial scale-up, unsuitable for industrial scale-up, complex operation, etc., achieving high industrial application value, suitable for Industrial scale-up and high film repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

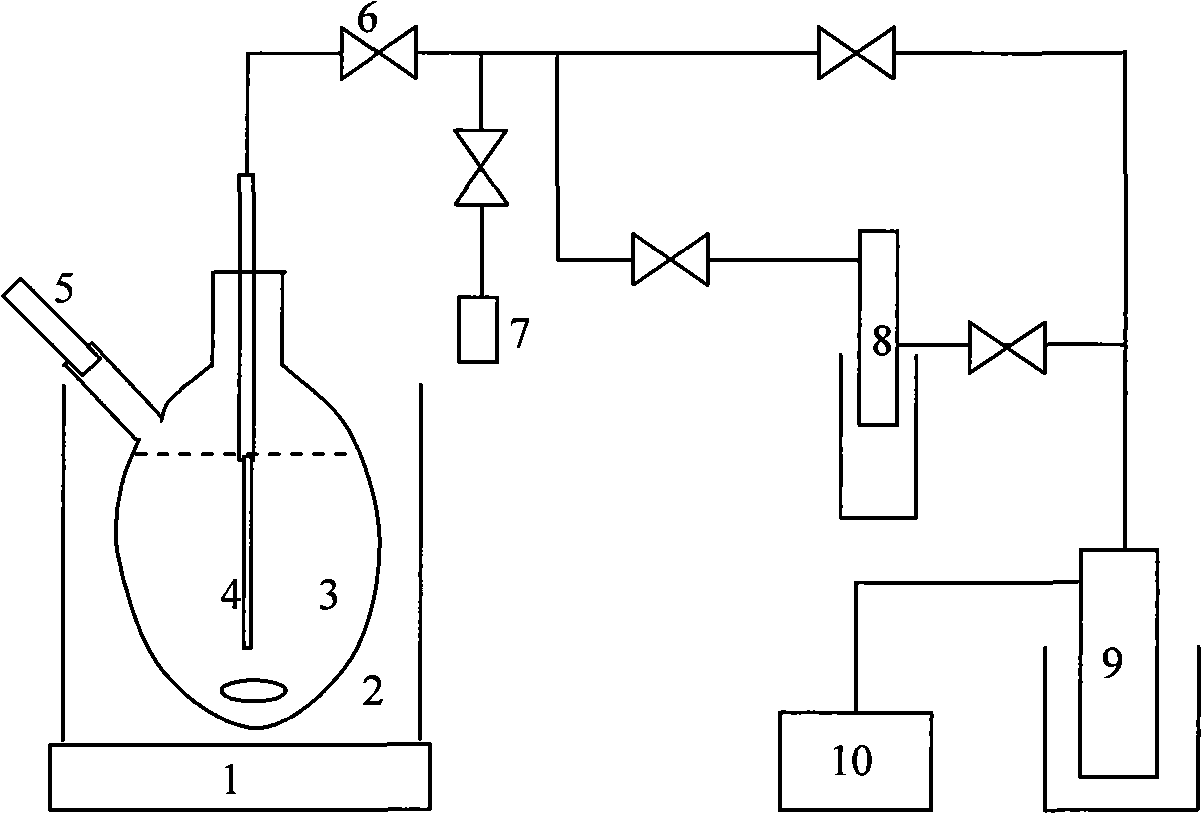

Method used

Image

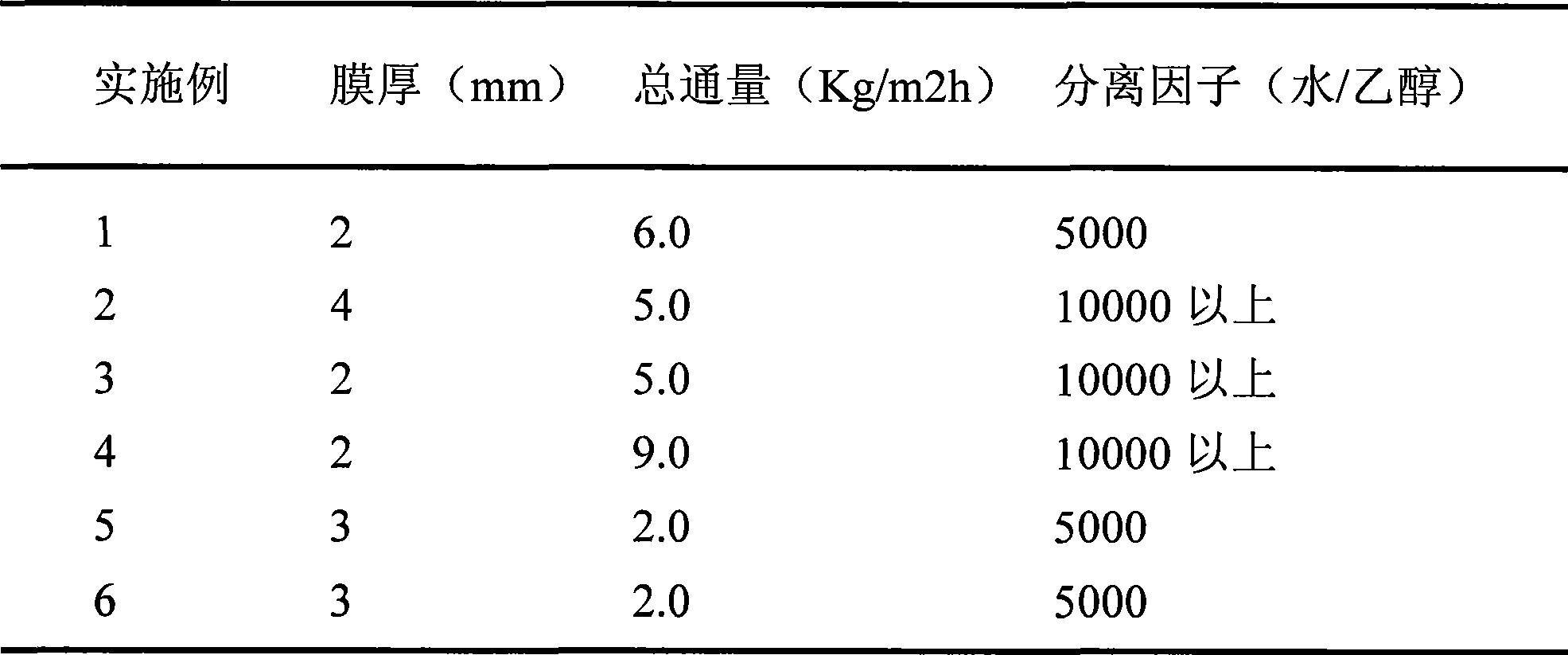

Examples

Embodiment 1

[0020] 1) Place A-type molecular sieve seeds in water and oscillate in ultrasonic waves to form a uniform molecular sieve suspension, the suspension concentration is 5g / L, the grain size is 0.2m, and the porous alumina hollow fiber (outer diameter 1.2mm , inner diameter 0.6mm, porosity 40%) the carrier is immersed in the molecular sieve suspension at a speed of 0.1cm / s by a pulling machine, pulled up at a speed of 0.1cm / s after dipping for 1s, and dried at 30°C. The dried carrier is rolled and rubbed on a lens cloth to obtain a seeded carrier;

[0021] 2) Add sodium metaaluminate to distilled water and stir fully to form an aluminum solution, dissolve sodium hydroxide in distilled water, add sodium metasilicate after clarification, heat and stir to form a silicon solution, add the aluminum solution to the silicon solution and stir, The reaction solution composition of the synthetic molecular sieve membrane made is: Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=1:1:1:50;

[0022]3) Pou...

Embodiment 2

[0024] 1) Place A-type molecular sieve crystal seeds in water and oscillate in ultrasonic waves to form a uniform molecular sieve suspension with a concentration of 20g / L and a grain size of 2m. The inner diameter is 0.6mm, the porosity is 30%), the carrier is immersed in the molecular sieve suspension at a speed of 1cm / s by a pulling machine, after dipping for 10s, it is pulled up at a speed of 1cm / s, and dried at 60°C. After the carrier is rolled on the lens cleaning cloth, the seeded carrier is obtained;

[0025] 2) Add sodium metaaluminate to distilled water and stir fully to form an aluminum solution, dissolve sodium hydroxide in distilled water, add sodium silicate after clarification, heat and stir to form a silicon solution, add the aluminum solution to the silicon solution and stir to prepare The reaction solution composition of the synthesized molecular sieve membrane is: Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=3.4:1:2:155;

[0026] 3) Pour the reaction liquid into the...

Embodiment 3

[0028] Same as Example 2, the silicon source is sodium metasilicate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com