Novel organic electroluminescent compounds and organic electroluminescent device using the same

A compound and luminescent technology, applied in electroluminescent light sources, indium organic compounds, platinum group organic compounds, etc., can solve the problem of not being able to provide pure red at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0186] [Preparation Example 1] Preparation of Compound (1)

[0187]

[0188] Preparation of compound (A)

[0189] 3-Aminonaphthalene-2-carboxylic acid (1.0 g, 5.4 mmol) was dissolved in THF (50 mL), and the temperature of the solution was lowered to 0°C. Phenyllithium (11.9 mL, 21.4 mmol) was slowly added to the solution. After stirring for 2 hours, aqueous ammonium chloride solution was added to the reaction mixture to quench the reaction. The resulting mixture was extracted with diethyl ether, and the extract was filtered under reduced pressure. Purification by silica gel column chromatography gave Compound (A) (0.79 g, 60%).

[0190] Preparation of compound (B)

[0191] Add compound (A) (1.29 g, 5.24 mmol), acetophenone (0.55 ml, 4.76 mmol), acetic acid (7.13 ml) and sulfuric acid (0.04 ml) in a reaction vessel, under argon atmosphere, reflux conditions Stir down. When the reaction was completed, the reaction mixture was cooled to room temperature, and an excess ...

Embodiment 1

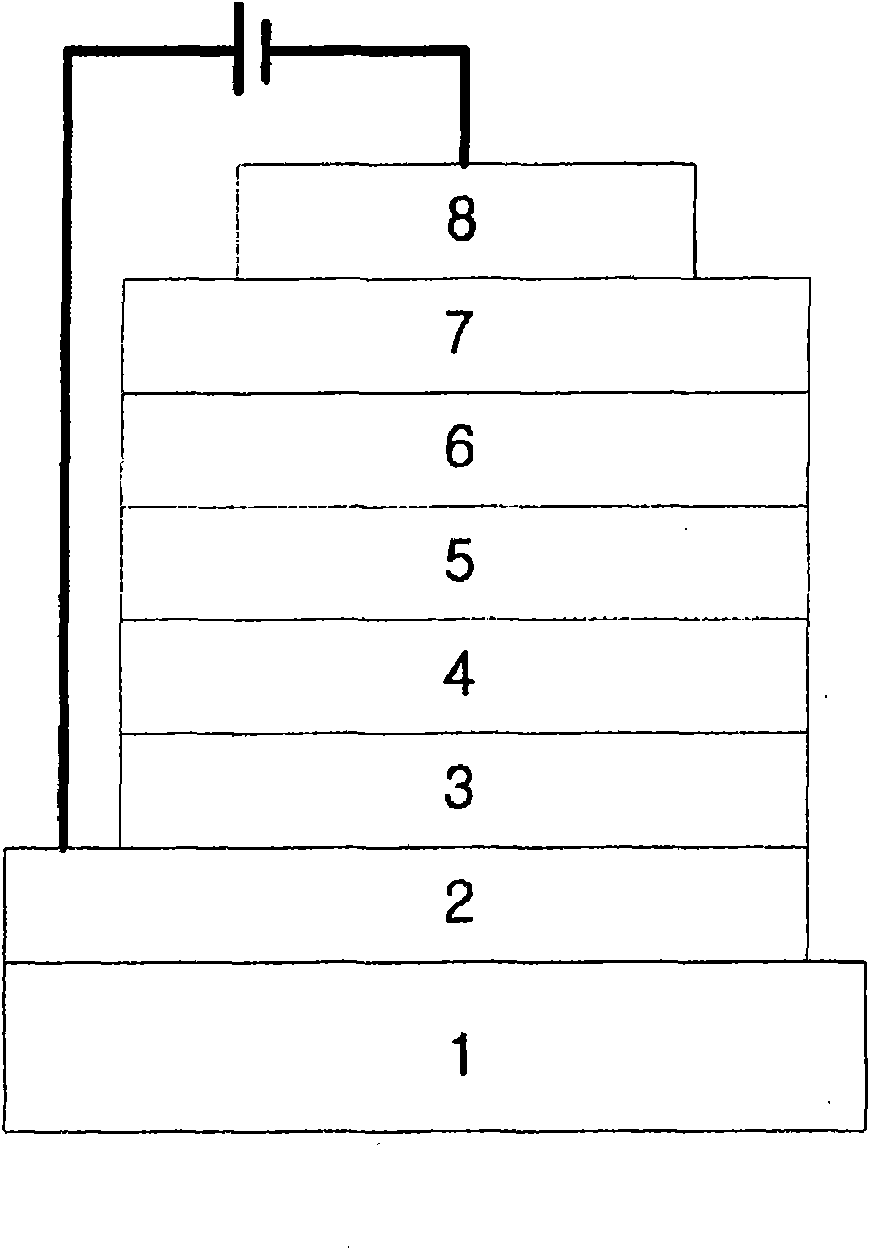

[0311] [Example 1] Manufacture of OLED (1)

[0312] OLED devices were fabricated using the red phosphorescent compounds of the present invention.

[0313] First, a thin film (15Ω / □) (2) of transparent electrode ITO made of glass for OLED (manufactured by Samsung Corning) (1) was ultrasonically cleaned with the following substances in order: trichloroethylene, acetone , ethanol, and distilled water, store in isopropanol until use.

[0314] Then, the ITO substrate is installed in the substrate folding machine of the vacuum vapor deposition equipment, and 4,4', 4 "-three (N, N-(2-naphthyl)-phenylamino) triphenylamine (2 -TNATA) is put into the chamber of this vacuum vapor deposition equipment, then this chamber ventilation makes indoor vacuum up to 10 -6 support. A current is applied in the chamber to evaporate 2-TNATA, thus vapor-depositing a 60 nm thick hole injection layer on the ITO substrate (3)

[0315]

[0316] Then, add N, N'-bis(α-naphthyl)-N, N'-diphenyl-4,4'-dia...

Embodiment 2

[0323] [Example 2] Manufacture of OLED (2)

[0324] After forming the hole injection layer and the hole transport layer in the manner of Example 1, the electroluminescence layer was vapor-deposited as follows. In another chamber of the vacuum vapor deposition apparatus, H-5 was added as an electroluminescence host material, and a phosphorescent compound of the present invention (Compound 61) was added in another chamber. The two substances are doped by evaporation at different rates, and an electroluminescent layer (5) with a thickness of 30 nanometers is vapor-deposited on the hole transport layer. Based on the host, the suitable doping concentration is 4-10% by weight. Then, a hole blocking layer, an electron transport layer, and an electron injection layer were vapor-deposited in the same manner as in Example 1, and an Al cathode was vapor-deposited with a thickness of 150 nanometers using another vacuum vapor deposition apparatus to manufacture an OLED.

[0325]

[03...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com