Visible light active boron-nickel co-doped titanium dioxide solid solution catalyst and preparation method thereof

A titanium dioxide, photocatalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve unseen problems and achieve great application potential and purity High, easy process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

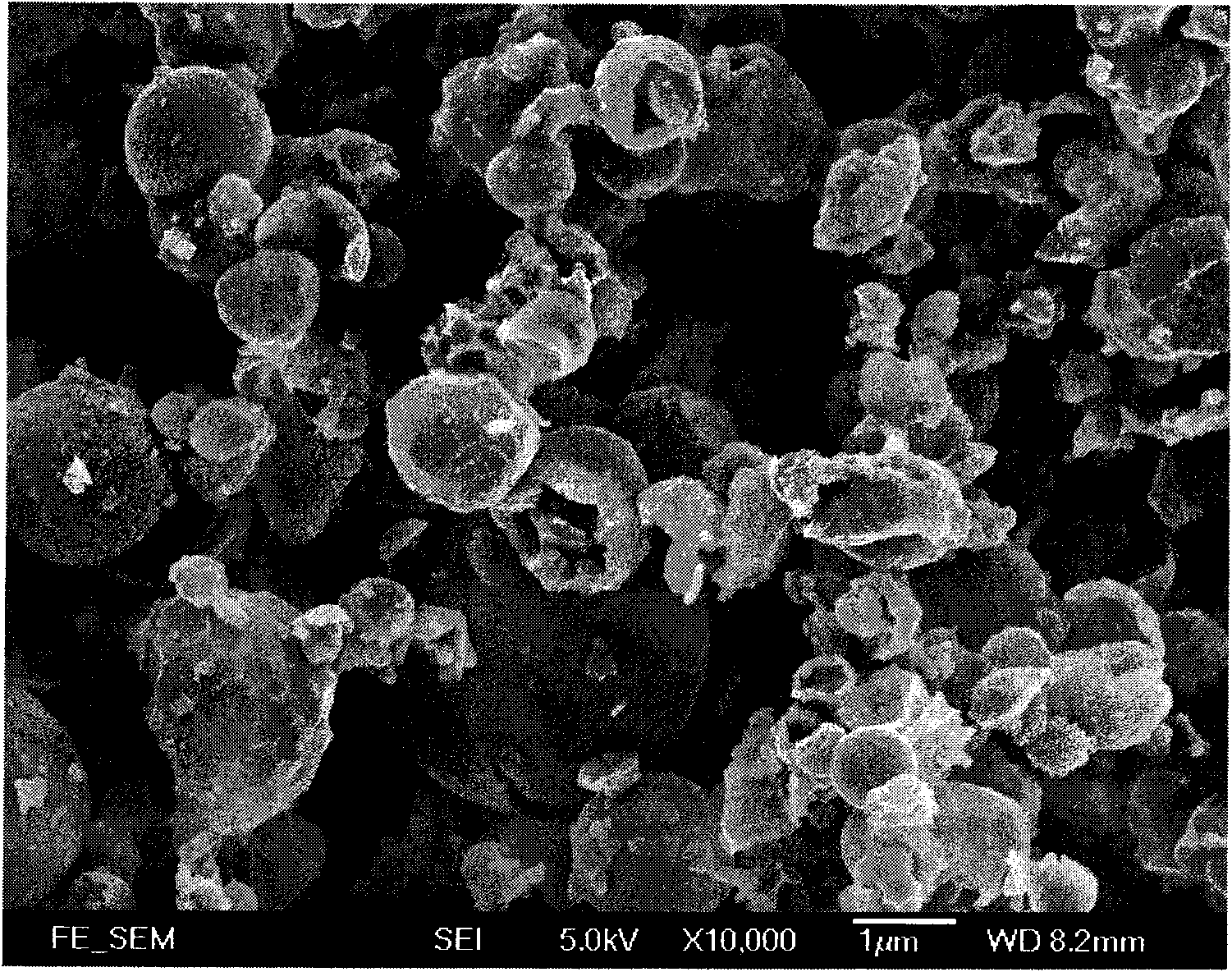

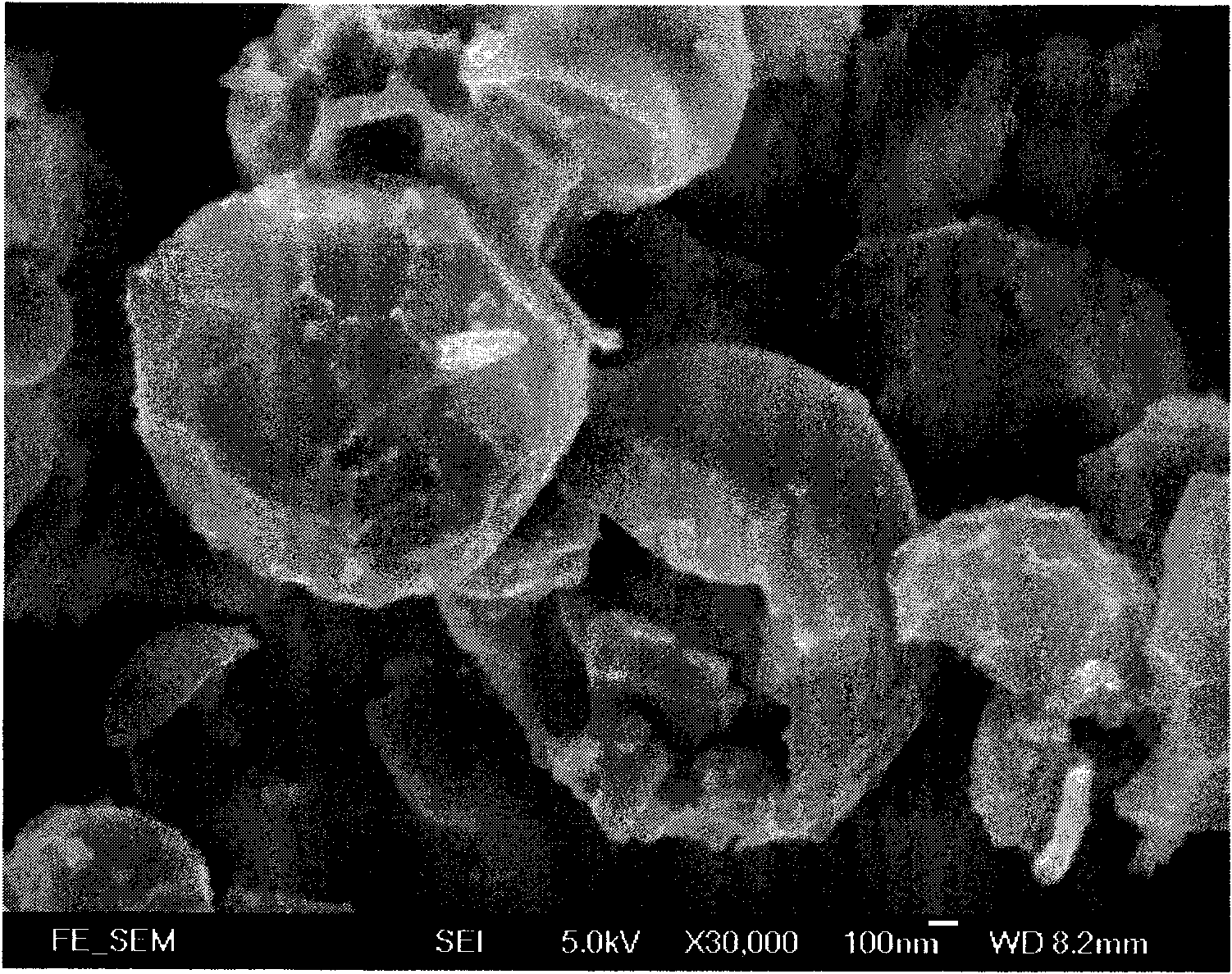

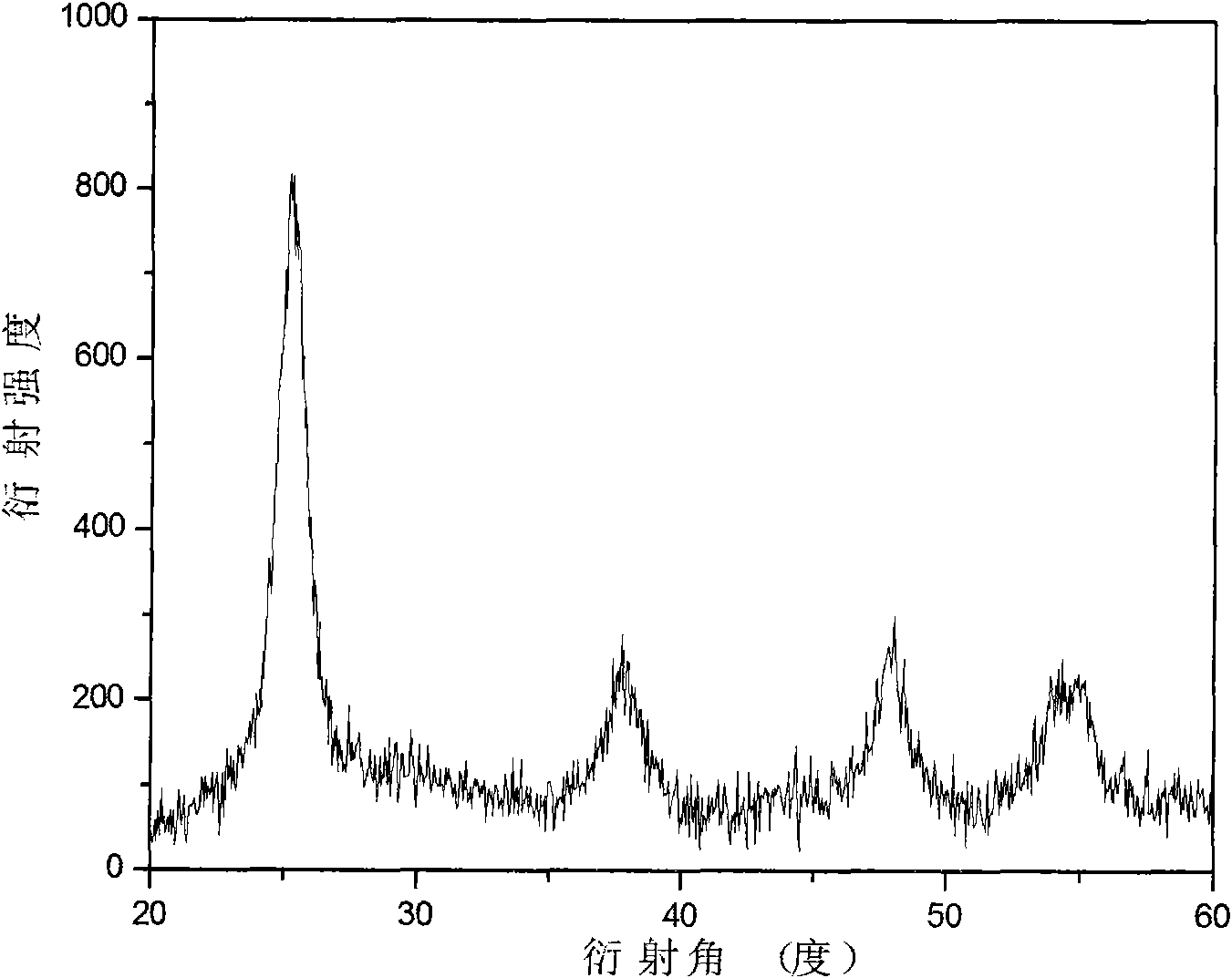

[0026] Preparation of boron-nickel co-doped titanium dioxide solid solution photocatalyst, the preparation steps are:

[0027] Step 1, using titanium tetrachloride as the raw material, under the condition of stirring, use distilled water at 4°C to prepare a titanium tetrachloride solution, the content of titanium ions in the solution is 5 mmol / L;

[0028] Step 2, in another container, configure boric acid and nickel chloride solution with 4°C distilled water, the content of boric acid in the solution is 5mmol / L; the content of nickel chloride in the solution is 0.5mmol / L;

[0029] Step 3, under the condition that the solution obtained in step 1 is under stirring, pour the solution obtained in step 2 into the solution obtained in step 1, and the volume ratio of the two solutions is 1:1;

[0030] Step 4. Pour the solution obtained in step 3 into a container of an ultrasonic nebulizer, spray and pyrolyze it in an air atmosphere at 500°C, and react for 1 hour;

[0031] Step 5. Af...

Embodiment 2

[0035] Preparation of boron-nickel co-doped titanium dioxide solid solution photocatalyst, the preparation steps are:

[0036] Step 1, using titanium tetrachloride as the raw material, under the condition of stirring, use distilled water at 4°C to prepare a titanium tetrachloride solution, the content of titanium ions in the solution is 20mmol / L;

[0037] Step 2, in another container, configure boric acid and nickel chloride solution with 4°C distilled water, the content of boric acid in the solution is 20mmol / L; the content of nickel chloride in the solution is 2mmol / L;

[0038] Step 3, under the condition that the solution obtained in step 1 is under stirring, pour the solution obtained in step 2 into the solution obtained in step 1, and the volume ratio of the two solutions is 1:1;

[0039] Step 4. Pour the solution obtained in step 3 into a container of an ultrasonic nebulizer, spray and pyrolyze it in an air atmosphere at 600°C, and react for 2 hours;

[0040] Step 5. Af...

Embodiment 3

[0043] Preparation of boron-nickel co-doped titanium dioxide solid solution photocatalyst, the preparation steps are:

[0044] Step 1, using titanium tetrachloride as the raw material, under the condition of stirring, use distilled water at 4°C to prepare a titanium tetrachloride solution, the content of titanium ions in the solution is 10mmol / L;

[0045] Step 2. In another container, configure sodium borohydride and nickel sulfate solutions with 4°C distilled water. The content of sodium borohydride in the solution is 10mmol / L; the content of nickel sulfate in the solution is 1mmol / L;

[0046] Step 3, under the condition that the solution obtained in step 1 is under stirring, pour the solution obtained in step 2 into the solution obtained in step 1, and the volume ratio of the two solutions is 1:1;

[0047] Step 4. Pour the solution obtained in step 3 into a container of an ultrasonic nebulizer, spray and pyrolyze it in an air atmosphere at 700°C, and react for 0.5 hours;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com