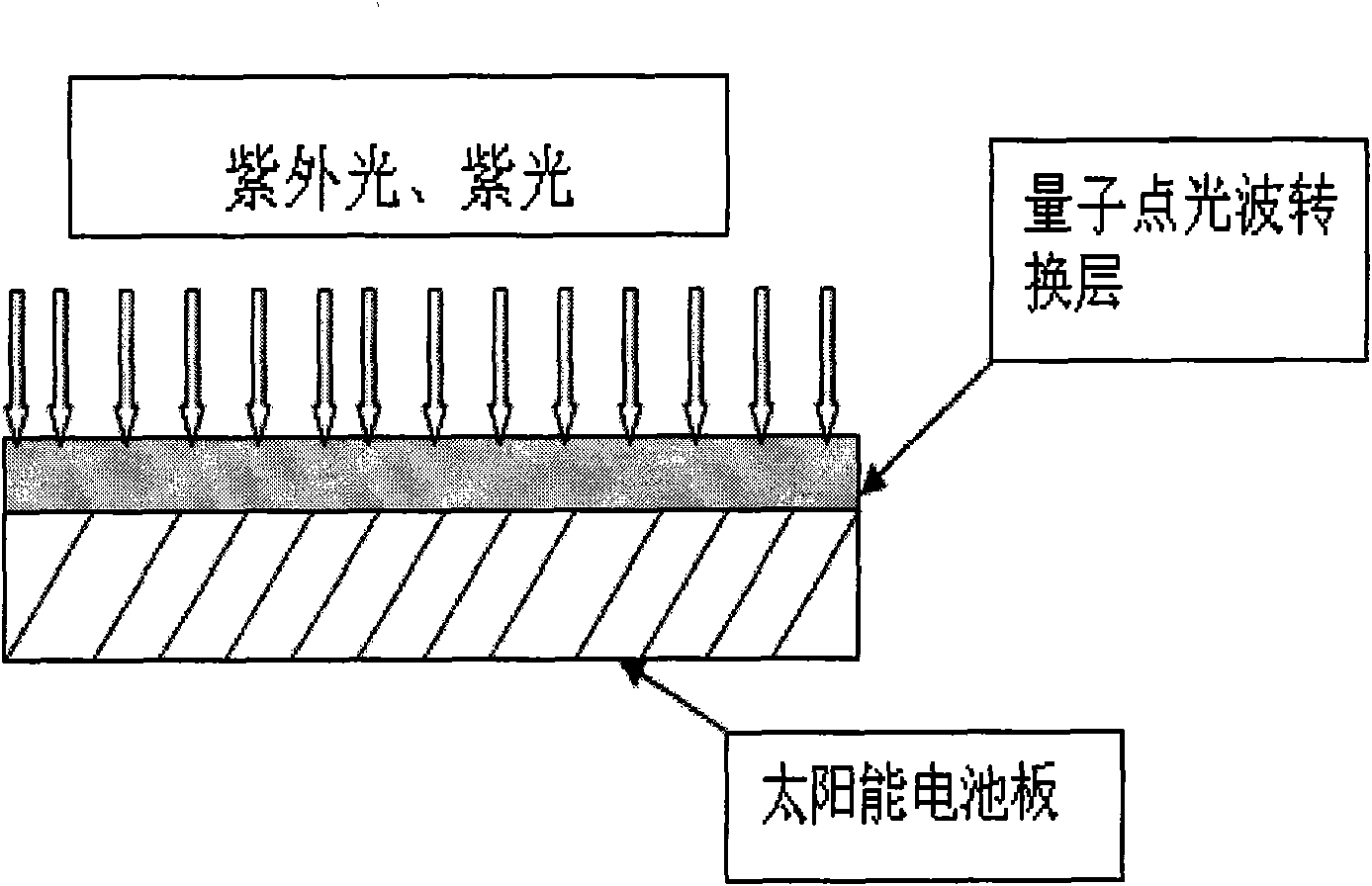

Method for preparing quantum dot light-wave conversion layer on the surface of silica-based solar cell

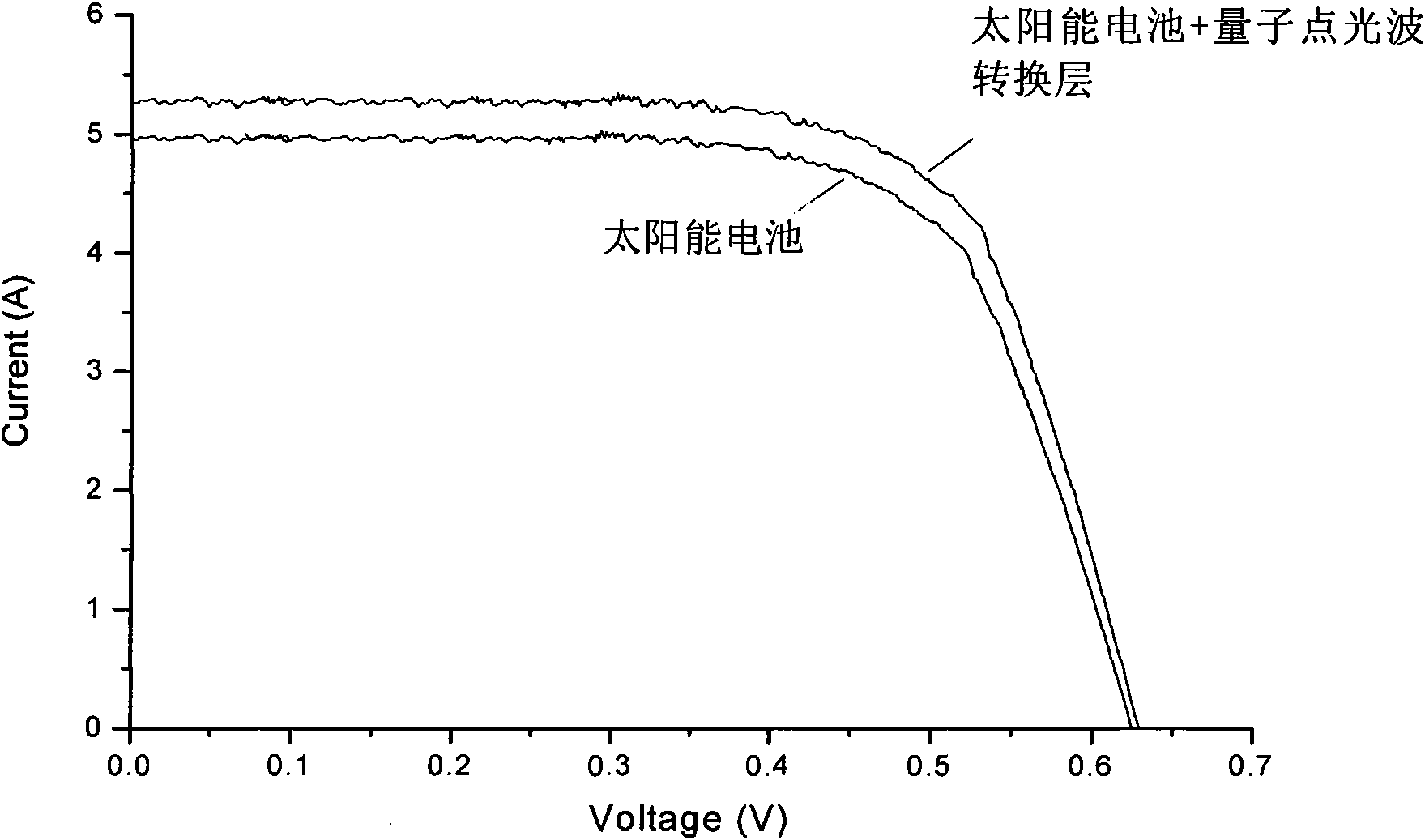

A solar cell, light wave conversion technology, applied in coatings, circuits, electrical components, etc., can solve the problems of low quantum efficiency, solar energy loss, etc., achieve high photoelectric conversion rate, improve photoelectric conversion efficiency, chemical and thermal stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The CdS quantum dot material is mixed into a silica sol system to obtain a quantum dot lightwave conversion composite material, and then coated on the surface of a silicon-based solar cell to form a quantum dot lightwave conversion layer. The preparation includes the following steps:

[0035] a. Preparation of silica sol

[0036] Take 10mL of ethyl orthosilicate with a concentration of 1.27mol / L, 25mL of absolute ethanol, 0.25mL of 2mol / L of hydrochloric acid, and 8mL of deionized water, and then use the hot solvent method to magnetically place the mixture in a 50℃ water bath. Stir for 3 hours to obtain a silica sol solution.

[0037] b. Preparation of CdS quantum dot nanomaterials

[0038] Take 25ml of 3.2mmol / L cadmium chloride (CdCl2·2.5H2O) solution and 10ml of 5% polyvinylpyrrolidone solution (PVP) by mass and stir at room temperature for 2 hours, then add 3.2mmol / L sodium sulfide (Na2S· 15ml of 9H2O) solution was added dropwise to the above mixed solution and stirred ...

Embodiment 2

[0046] The CdTe quantum dot material is mixed into a silica sol system to obtain a quantum dot lightwave conversion composite material, and then coated on the surface of a silicon-based solar cell to form a quantum dot lightwave conversion layer. The preparation includes the following steps:

[0047] a. Preparation of silica sol

[0048] Take 10mL of ethyl orthosilicate with a concentration of 1.27mol / L, 25mL of absolute ethanol, 0.25mL of 2mol / L of hydrochloric acid, and 8mL of deionized water, and then use the hot solvent method to magnetically place the mixture in a 50℃ water bath. Stir for 3 hours to obtain a silica sol solution.

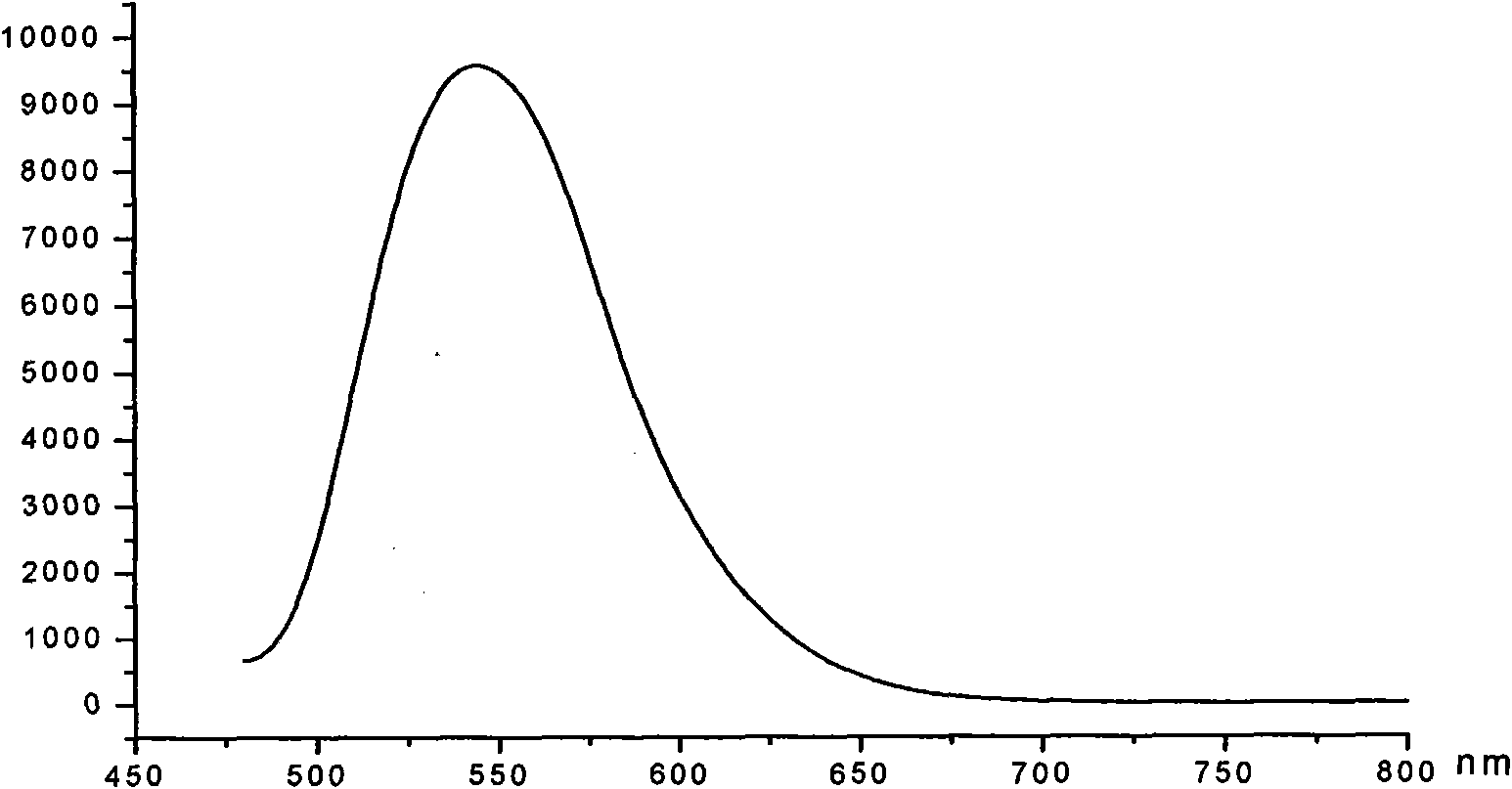

[0049] b. Preparation of CdTe quantum dot nanomaterials

[0050] Place 0.005mol Te powder in a beaker, add 10ml (2.2×10-1mol / L) sodium borohydride (NaBH4) aqueous solution, let stand for a few minutes until the black Te powder gradually dissolves to form a colorless and transparent NaHTe aqueous solution, take 1mol After mixing 10ml of cadmium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com