Yeast protein concrete foaming agent and preparation method thereof

A yeast protein and protein technology, applied in the field of yeast cell protein concrete foaming agent and its preparation, can solve the problems of limited source of plant raw materials, long production cycle of raw materials, development and application constraints, etc., and achieve easy mass acquisition or large-scale Cultivation, easy large-scale cultivation, and the effect of improving various performances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

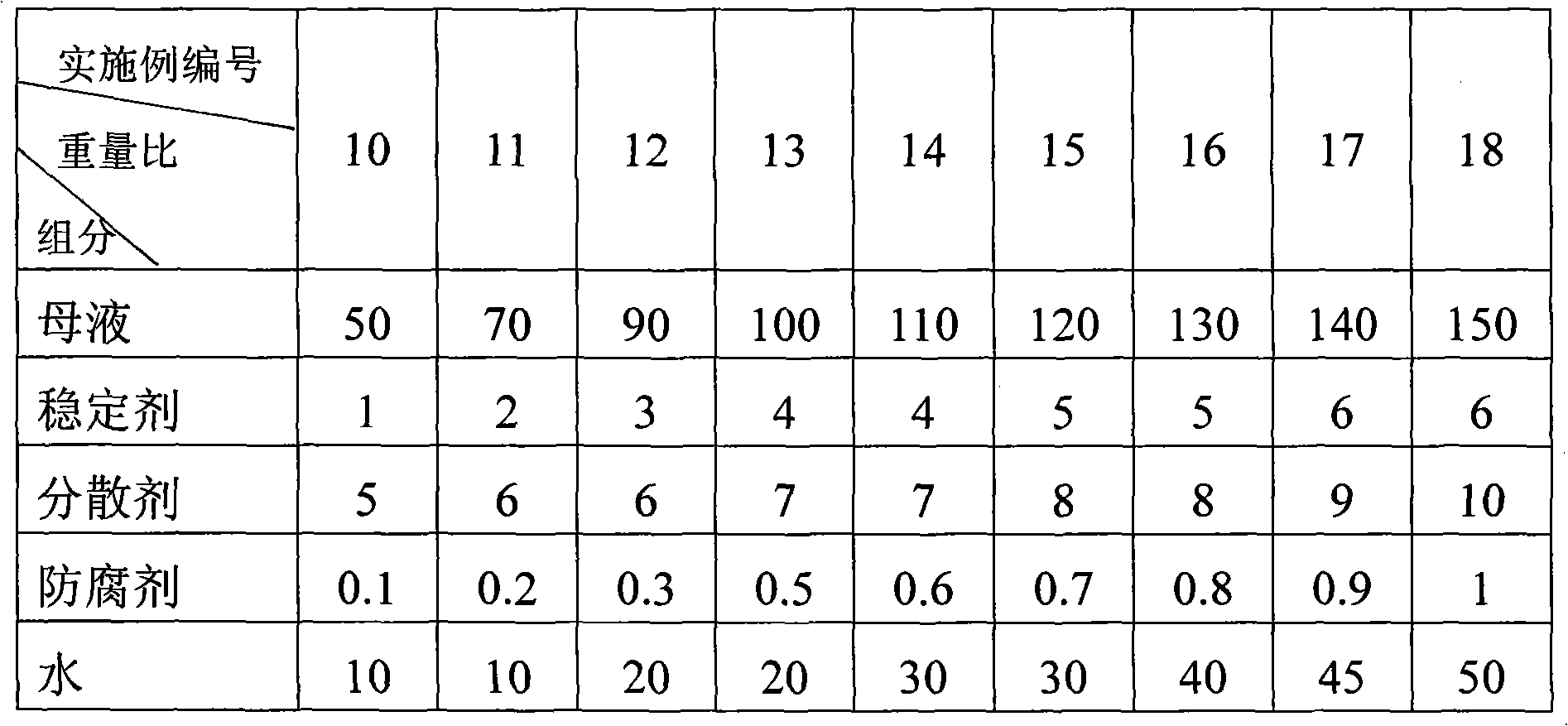

Examples

Embodiment 1

[0043] A preparation method for yeast cell protein concrete foaming agent, comprising the following steps:

[0044] a. Preparation of yeast protein:

[0045] Get 30Kg of beer fermentation industrial waste yeast cells (the leftovers of beer production, the protein content in its dry matter reaches 45%-55%, and the other components are barley pericarp, seed coat and barley mixed with yeast through yeast fermentation) hop fragments, etc.), diluted with cold water at 5°C, and the amount of water added was 3.5 times the weight of the yeast cells of beer fermentation industrial waste; once passed through an 80-mesh sieve, 80% of the impurities could be removed, and then sieved with a 100-mesh sieve Once, all visible impurities can be removed to obtain the crude product filtrate; stand still for 30 minutes to allow automatic precipitation, and pour out the supernatant liquid; take 4 times the weight of the lower material at 10 ℃ sterile water for 3 times to wash the lower material, a...

Embodiment 2

[0053] A preparation method for yeast cell protein concrete foaming agent, comprising the following steps:

[0054] a. Preparation of yeast protein:

[0055] Peel the potatoes, add twice the amount of water of the weight of the peeled potatoes, boil for 30-50min, filter and remove the potato dregs, add 2-2.5 times the volume of distilled water in the filtrate, and add 1-5% (percentage by weight, The same as in the following) to obtain liquid culture medium, and sterilize, get a ring of slanted brewer's yeast strain, inoculate in the liquid culture medium of 5-20ml, inoculum size (breer's yeast strain ratio liquid medium mass ratio) is 0.2-2%, culture temperature 20-35 ℃, culture time 40-70h, pH value 4.5-6, obtain yeast seed liquid, standby; Composition and weight percentage ratio is 5-10% refined flour, 1-5% Glucose, 0.01-0.05% epigermose, 0.01-0.02% ammonium sulfate, 0.01-0.02% potassium chloride, and 85-93% soybean juice are mixed to prepare a solid medium, and yeast seed ...

Embodiment 3

[0064] A preparation method for yeast cell protein concrete foaming agent, comprising the following steps:

[0065] a. Preparation of yeast protein:

[0066] Peel the potatoes, add twice the amount of water of the weight of the peeled potatoes, boil for 30-50min, filter and remove the potato dregs, add 2-2.5 times the volume of distilled water in the filtrate, and add 1-5% (percentage by weight, The same as in the following) to obtain liquid culture medium, and sterilize, get a ring of slanted brewer's yeast strain, inoculate in the liquid culture medium of 5-20ml, inoculum size (breer's yeast strain ratio liquid medium mass ratio) is 0.2-2%, culture temperature 20-35℃, culture time 40-70h, pH value 4.5-6, get the yeast seed liquid, spare; the composition and weight percentage ratio is 5-10% refined flour, 1-5% Glucose, 0.01-0.05% epigermose, 0.01-0.02% ammonium sulfate, 0.01-0.02% potassium chloride, and 85-93% soybean juice make a solid medium, and get yeast seed liquid (ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com