Lead-free piezoceramics-polymer piezoelectric composite material and preparation method thereof

A ceramic material, piezoelectric composite technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problem of no lead-free piezoelectric ceramics, achieve good piezoelectric performance and dielectric performance, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The powder tablet press used in this example is the 769YP-24B type of Tianjin Keqi High-tech Company; the ion sputtering device is the SBC-12 type of Beijing Zhongke Keyi Technology Development Co., Ltd.

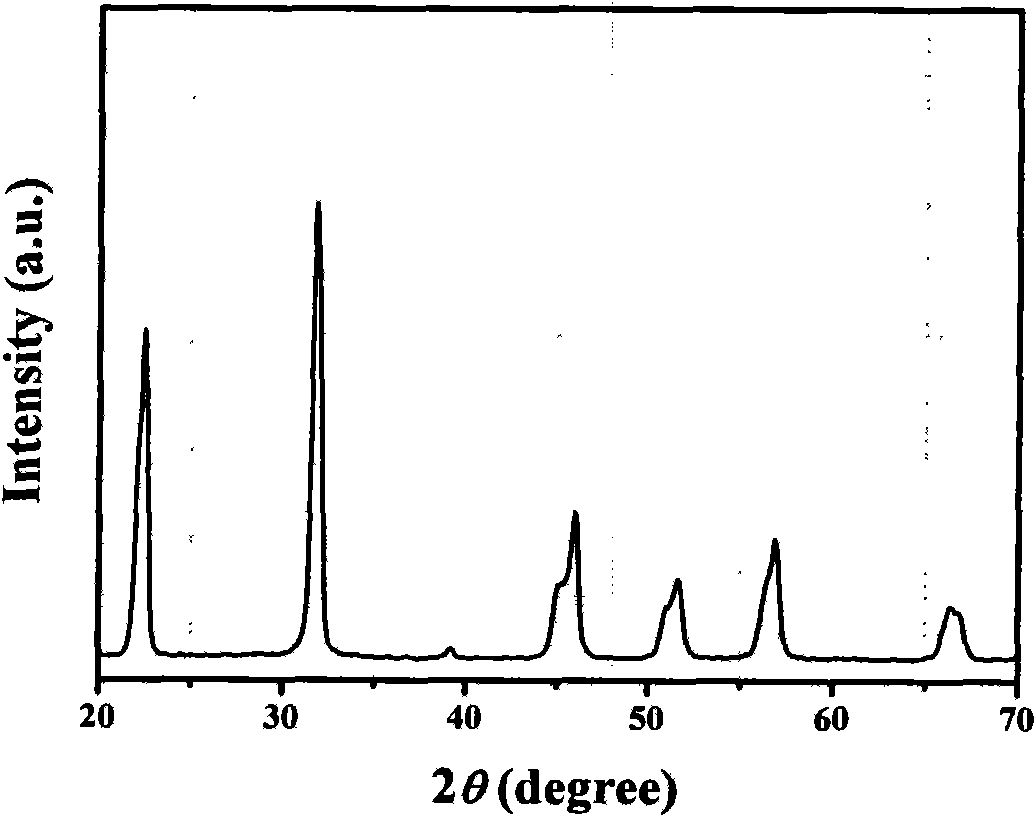

[0027] According to the general formula (1-x)(K b Na 1-b )NbO 3 -xLiSbO 3 (x=0.052, b=0.052) the stoichiometric ratio of [KNNLS] carries out weighing raw material, to analyze pure anhydrous sodium carbonate (Na 2 CO 3 ), anhydrous potassium carbonate (K 2 CO 3 ), niobium pentoxide (Nb 2 o 5 ), lithium carbonate (Li 2 CO 3 ), and antimony trioxide (Sb 2 o 3 ) as raw materials, using the traditional process of preparing lead-free piezoelectric ceramics, that is, through ball milling and calcination to complete the pre-synthesis, then granulation, high-pressure molding into green body, after debinding, normal pressure sintering into porcelain; The KNNLS ceramic powder after granulation is mixed according to the volume ratio of ceramic powder and polyvinyliden...

Embodiment 2

[0031] Used powder tablet press and ion sputtering apparatus are identical with embodiment 1.

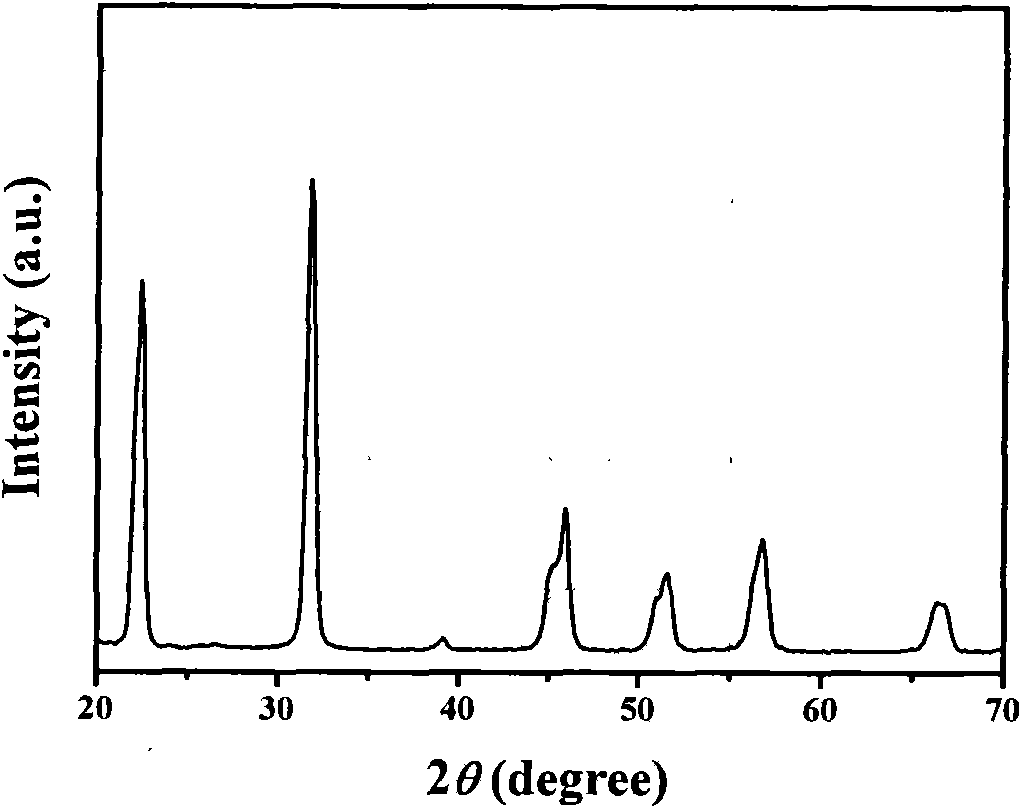

[0032] According to the general formula (1-x)(K b Na 1.15-b )NbO 3 -xLiNbO 3 (x=0.058, b=0.48) the stoichiometric ratio of [KNLN] carries out weighing raw material, to analyze pure anhydrous sodium carbonate (Na 2 CO 3 ), anhydrous potassium carbonate (K 2 CO 3 ), niobium pentoxide (Nb 2 o 5 ), and lithium carbonate (Li 2 CO 3 ), as raw materials, using the traditional process of preparing lead-free piezoelectric ceramics, that is, through ball milling and calcination to complete the pre-synthesis, then granulation, high-pressure molding into a green body, and normal pressure sintering into porcelain after debinding; The fine-grained KNLN ceramic powder is mixed according to the volume ratio of ceramic powder and polyvinylidene fluoride powder at a ratio of 78:22, and ball milled with absolute ethanol as the ball milling medium for 18 hours, then dried, and the dried mixtu...

Embodiment 3

[0036] Used powder tablet press and ion sputtering apparatus are identical with embodiment 1.

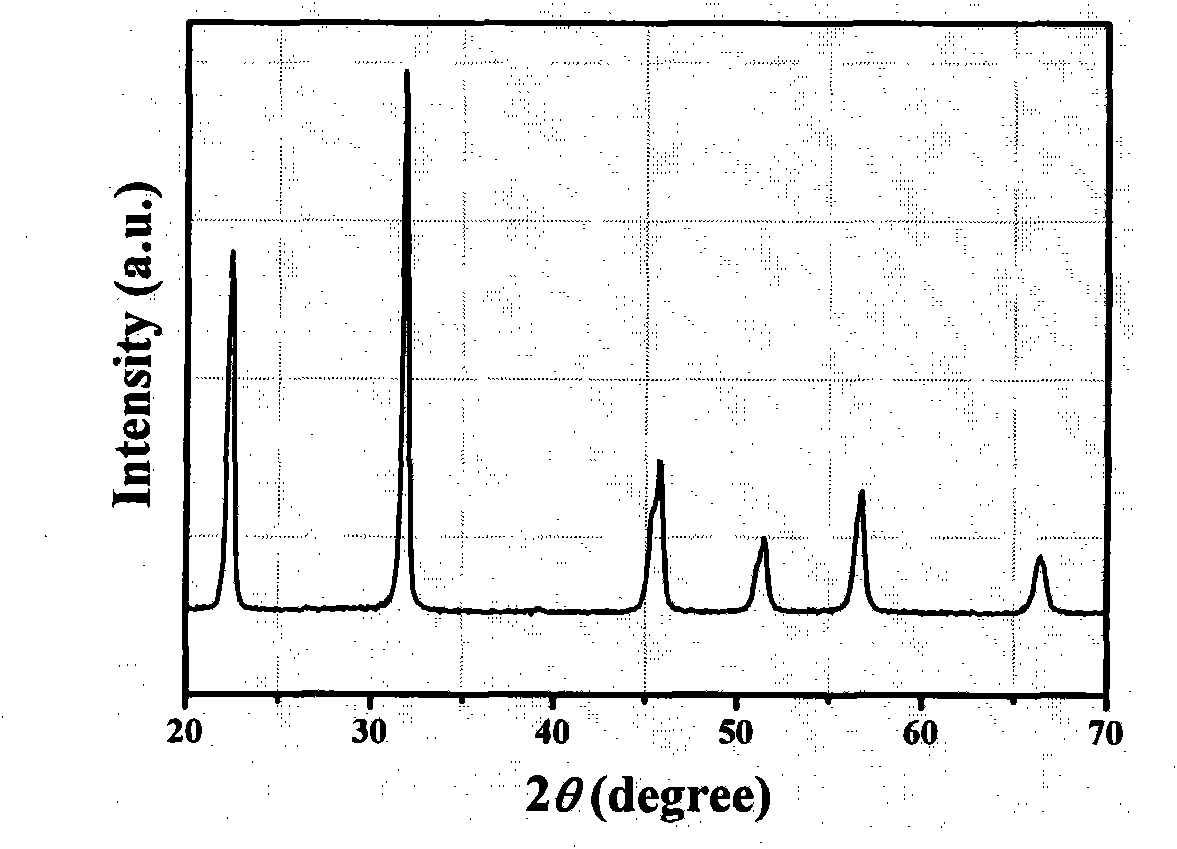

[0037] According to the general formula (1-x)(K b Na 1-b )NbO 3 -xBiScO 3 -yMnCO 3 (x=0.02, b=0.5, y=0.008) the stoichiometric ratio of [KNNBSM] carries out weighing raw material, to analyze pure anhydrous sodium carbonate (Na 2 CO 3 ), anhydrous potassium carbonate (K 2 CO 3 ), niobium pentoxide (Nb 2 o 5 ), bismuth trioxide (Bi 2 o 3 ), scandium trioxide (Sc 2 o 3 ) and manganese carbonate (MnCO 3 ) as raw materials, using the traditional process of preparing lead-free piezoelectric ceramics, that is, through ball milling and calcination to complete the pre-synthesis, then granulation, high-pressure molding into green bodies, and sintering into ceramics under normal pressure after debinding. The KNNBSM ceramic powder crushed into fine particles was mixed according to the volume ratio of ceramic powder and polyvinylidene fluoride powder at a volume ratio of 78:22, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com