Liquid biochip system

A liquid chip and chip technology, applied in biological testing, material inspection products, instruments, etc., can solve the problems of small amount of modified samples, insufficient chip bonding, and inability to ensure full chip bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

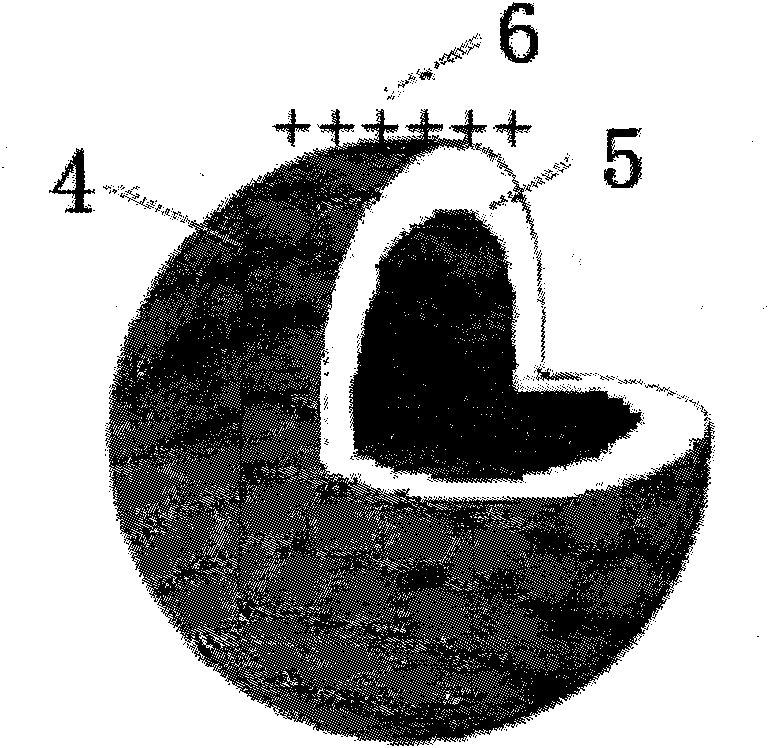

[0073] Embodiment one: the preparation of microbead

[0074] 1. Chitosan Microbeads

[0075] Chitosan (chitosan), chemical name (1,4)-A-amino-A-deoxy-B-D-glucan, is a copolymer of N-deacetylglucosamine, because chitosan and its derivatives are free of Toxicity, biodegradability and good biocompatibility, it is widely used as immobilized carrier of enzymes and cells.

[0076] The following is the preparation process of chitosan microbeads: weigh chitosan 9, dissolve it in 300mL of 2% acetic acid solution, stir continuously for 2 hours to fully dissolve, remove insoluble matter by suction filtration, add Tween-80 10mL, oil Phase dispersion medium, porogen ethyl acetate, emulsifier and polymer surface modifier, fully stirred and reacted at 50°C for 30 minutes, raised the temperature to 60°C, added formaldehyde solution, reacted for 30 minutes, then added 2.0ml of glutaraldehyde, Adjust the pH to 9.0, raise the temperature to 80°C, and react for 60 minutes. Suction filter, wash ...

Embodiment 2

[0102] Example 2: Surface functional group modification of microbeads

[0103] 1. Surface affinity modification process of chitosan microbeads

[0104] Add appropriate amount of deionized water to chitosan microbeads, activate with epichlorohydrin, add EDC and heparin, and stir at 4°C for 24 hours to obtain surface affinity-modified microbeads.

[0105] The long-chain alkyl group of chitosan microbeads is used as the hydrophobic part, and the sulfate group is used as the hydrophilic part to synthesize N-octyl-O-sulfate chitosan (OCS1) to obtain microbeads with surface hydrophilic modification.

[0106] 2. Surface ion exchange modification process of cellulose microbeads

[0107] Add the washed cellulose microbeads to a solution containing 0.1mol / L DEAE hydrochloride and 0.5mol / L NaOH, and keep stirring at 60°C for 10 hours to make it cross-link-DEAE weakly basic anion exchange group group.

[0108] 3. Metal chelation affinity modification of microbeads

[0109] Add microbe...

Embodiment 3

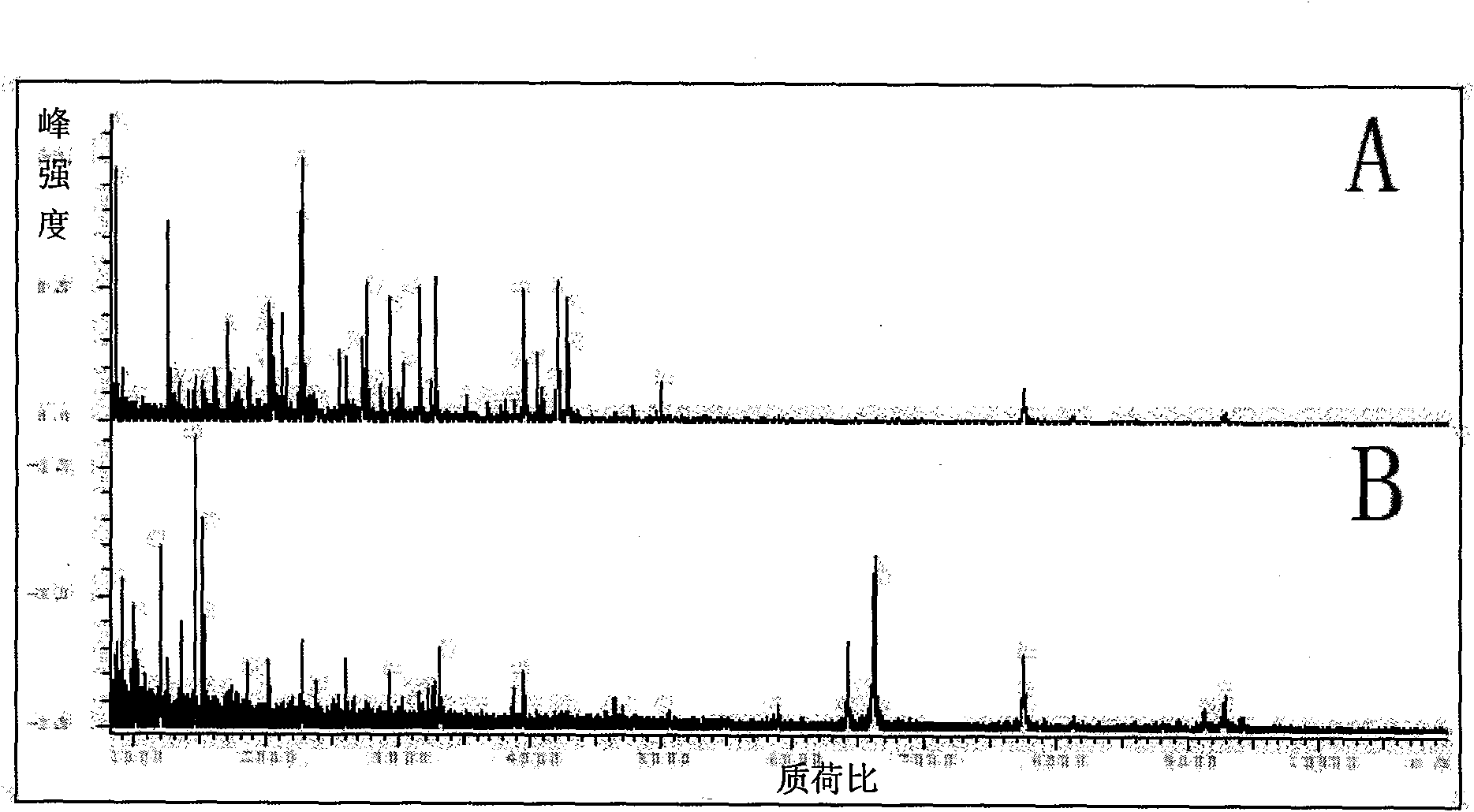

[0115] Example 3: Binding, purification and identification of acidic protein and metal binding protein

[0116] (1) Take 98ul of binding buffer in a 0.5ml eppendorf tube and add 2ul of serum. Select a weak cation binding separation device, fix the separation device at the front end of a 20-200ul pipette, draw the sample in the EP tube, gently pipette back and forth 5 times, and let it stand for 1min. Blow off the sample. Add 0.6ml of washing buffer into the 1.5ml EP tube, adjust the pipette to 120ul to absorb the washing buffer, pipette in another EP tube three times, discard the washing buffer, and repeat this three times. Aspirate 20ul of elution buffer and let stand for 2mins. Aspirate the eluate into a new 0.2ul EP tube. The eluate can be detected and identified by protein spectrum, and the results are as follows: figure 2 -A, wherein the abscissa represents the mass-to-charge ratio of the detected protein (wherein the charge is 1), and the ordinate is the peak intens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com