Sol-gel method for preparing lithium ferrous phosphate anode material based on ferric phosphate

A technology for lithium ferrous phosphate and positive electrode materials, which is applied in electrode manufacturing, battery electrodes, electrical components, etc., can solve the problems that limit the large-scale industrialization of lithium ferrous phosphate, poor high-current discharge capacity of synthetic materials, and harsh control conditions. , to achieve the effect of excellent cycle performance, low price, uniform and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] In order to solve the technical problems, the present invention provides a sol-gel preparation method of lithium iron phosphate, a positive electrode material for lithium ion batteries based on iron phosphate. The specific implementation steps are: using iron phosphate and lithium source compounds as raw materials, Mix in proportion, add carbon source and organic complexing agent, dissolve in distilled water, heat and stir at 30-90°C for 0.5-5 hours until a sol is formed, dry the sol to obtain a xerogel, mix it evenly and put it into a tube In a type furnace, it is pre-calcined at a constant temperature of 300-450°C for 4-12 hours under the protection of an inert gas, and finally calcined at a constant temperature of 500-800°C for 4-24 hours under the protection of an inert gas.

[0020] The lithium source used in the present invention can be selected from one of lithium hydroxide, lithium oxide, lithium nitrate, lithium carbonate, lithium oxalate, lithium acetate, lithi...

Embodiment 1

[0029] Weigh 1.1213g iron phosphate, 0.7943g oxalic acid, 0.4344g lithium nitrate and 0.2248g sucrose, add distilled water to dissolve, stir at 65°C for 2 hours to form a gel, then put it into an oven to dry to obtain a xerogel; After grinding, it was pressed into tablets, put into a tube furnace and pre-fired at 300° C. for 6 hours under the protection of an inert gas to obtain a lithium iron phosphate precursor.

[0030] The precursor is ground and then pressed into tablets, put into a tube furnace and calcined at 600° C. for 8 hours under the protection of an inert gas to obtain a lithium iron phosphate cathode material.

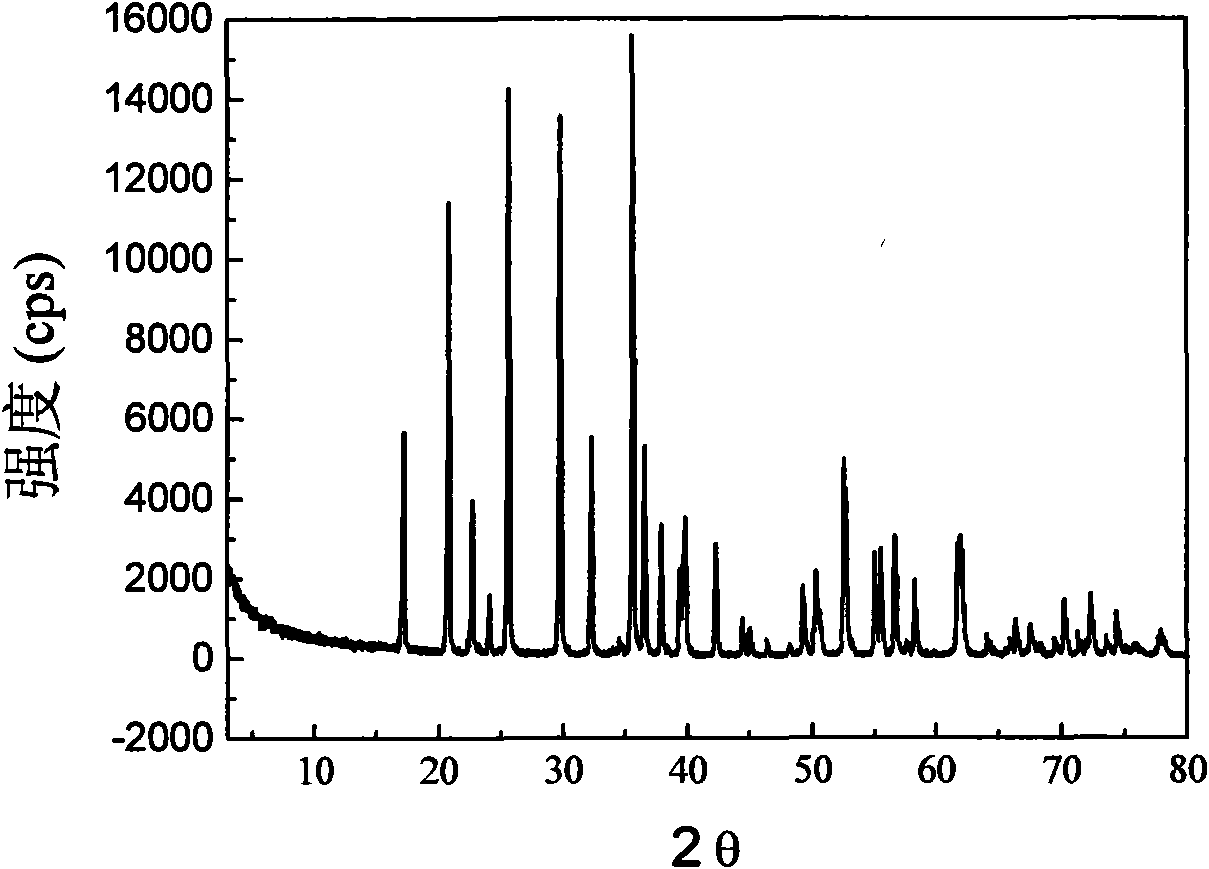

[0031] figure 1 For the XRD pattern of the obtained material, a Rigaku D / Max III type X-ray diffractometer (Cu target ka ray, wavelength λ=0.15418 nm) was used. Compared with the standard card, it can be seen that the synthesized material is olivine (space group Pnma), and no diffraction peak of carbon is found in the spectrogram, indicating that the car...

Embodiment 2

[0035] Weigh 1.1213g iron phosphate, 0.2216g lithium carbonate, 1.3238g citric acid, add distilled water to dissolve, stir and evaporate at 90°C for 1 hour to form a gel, then put it in an oven to dry to obtain a xerogel; grind the xerogel Tablets were put into a tube furnace and pre-fired at 400° C. for 3 hours under the protection of an inert gas to obtain a lithium iron phosphate precursor.

[0036] The precursor was ground and then pressed into tablets, put into a tube furnace and calcined at 650° C. for 6 hours under the protection of an inert gas to obtain a lithium iron phosphate cathode material.

[0037] The resulting material is made into an electrode as follows:

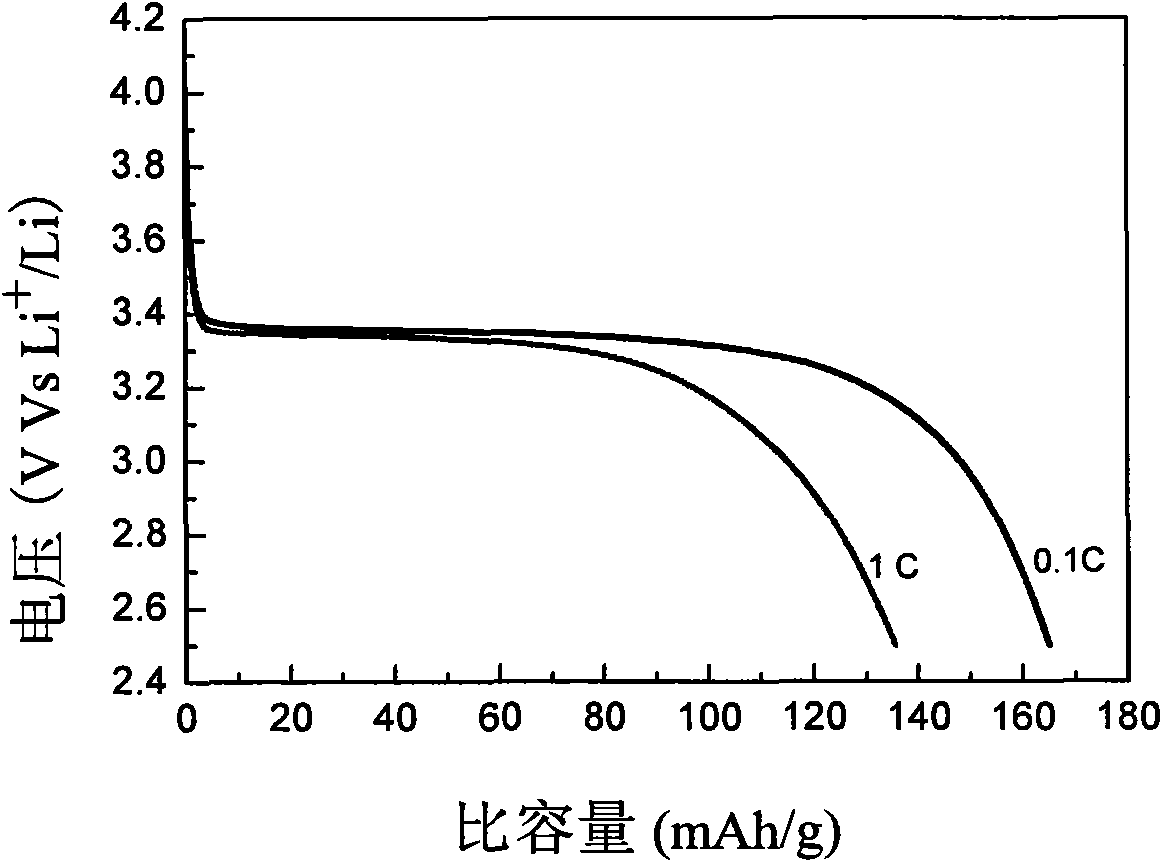

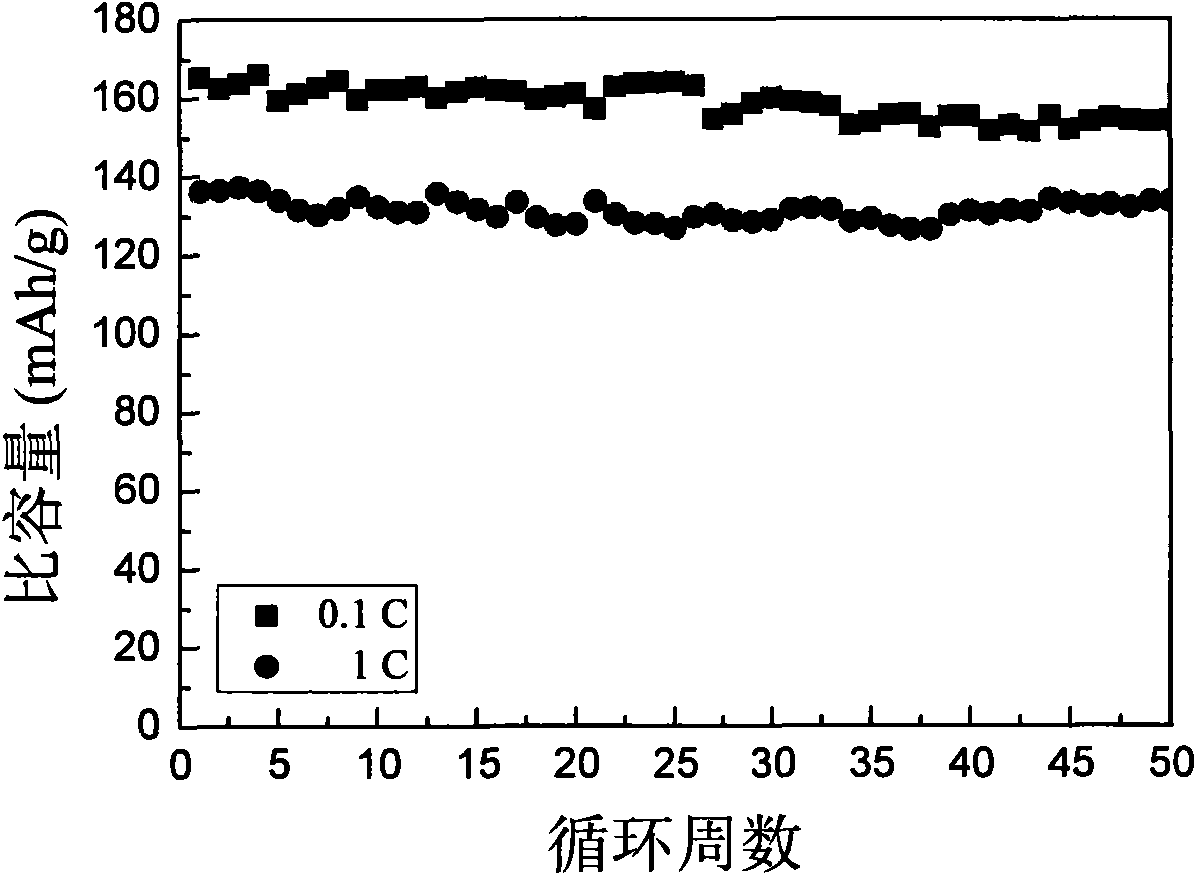

[0038] Weigh the material obtained in Example 2, conductive carbon and polytetrafluoroethylene with a mass ratio of 85:10:5, mix them evenly and grind them, then make a circular pole piece with a diameter of 8mm, and dry it in a drying oven at 100°C 24 hours to obtain the positive electrode sheet, with pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com