Method for synthesizing magnetic layered composite hydroxide

A composite hydroxide and synthesis method technology, which is applied in the field of synthesis of magnetic layered composite hydroxide, can solve problems such as instability, difficulty in preparation of pure crystalline phase LDH, and limitations on the development and utilization of magnetic LDH, and achieve uniform particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

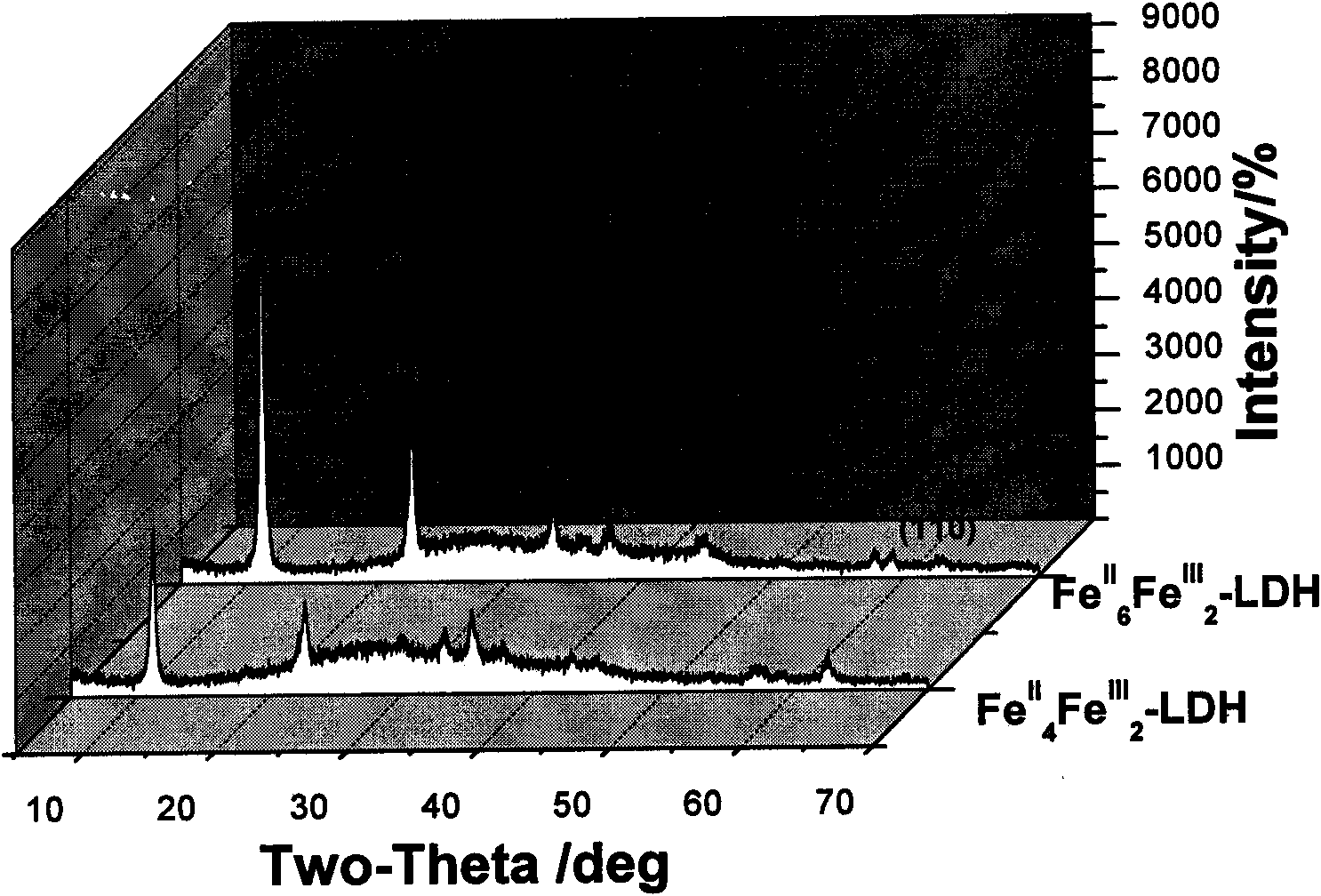

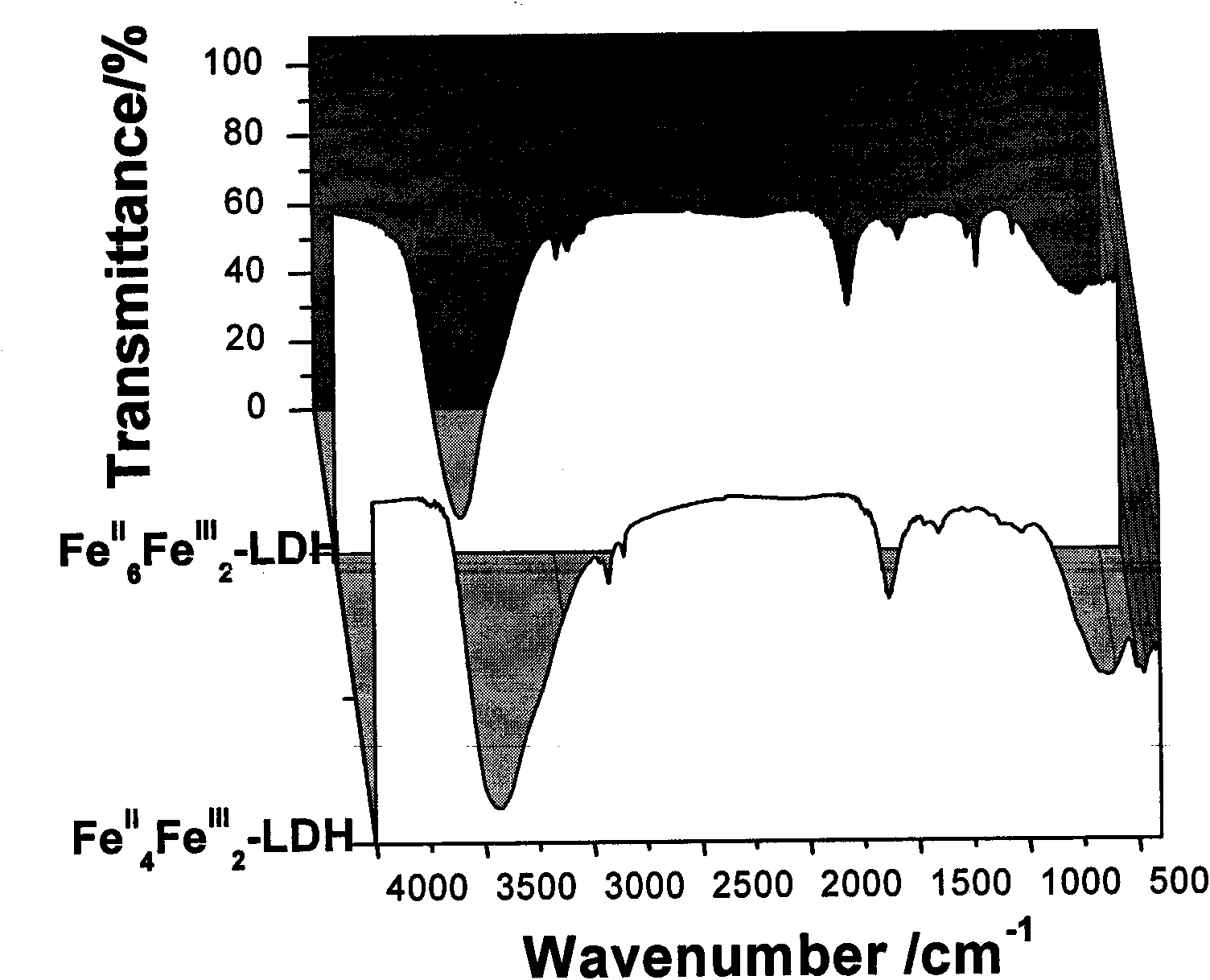

[0019] Take a certain amount of ferric salt and ferrous salt, in N 2 Press Fe in the atmosphere glove box 2+ / Fe 3+ A molar ratio of 3 is formulated into a certain volume of mixed salt solution, in which FeCl 2 The concentration is 1.50mol·L -1 , FeCl 3 The concentration is 0.50mol·L -1 , sealed and transferred to the synthesis reaction device; in constant flow N 2 -H 2 Add dropwise 2.0mol·L under the protection of mixed gas -1 NaOH solution to pH 6.0-8.0 at the end point, maintain the reaction temperature at 35-70°C by means of agitator and relay; the co-precipitation slurry is crystallized for 45-60 minutes under the same stirring speed, protective gas flow rate and 35-70°C go to N 2 Atmosphere glove box, centrifuge the slurry, discard the centrifugate, and use twice distilled water for the solid phase in N 2 Wash and centrifuge three times under the action of bubbling, then wash with ethanol in the same way to remove water, and finally treat with ether once; the so...

Embodiment 2

[0022] Press Fe 2+ / Fe 3+ A certain amount of ferric salt and ferrous salt is placed in the reaction device with a molar ratio of 2, and the constant speed N 2 -H 2 Mixed gas to remove the air in the system, add a certain amount of double distilled water under the protection of constant flow of nitrogen and hydrogen, stir and dissolve, then add 2.0mol·L dropwise -1 NaOH solution to pH 6.0-8.0 at the end point, maintain the reaction temperature at 35-70°C by means of agitator and relay; the co-precipitation slurry is crystallized for 45-60 minutes under the same stirring speed, protective gas flow rate and 35-70°C go to N 2 Atmosphere glove box, separate the slurry, discard the centrifugate, use twice distilled water for the solid phase N 2 Gas bubbling washing, centrifugation three times, ethanol rinsing to bring out water, then treated with ether; solid phase at 50-70°CN 2 Put it in an atmosphere oven for 12 to 24 hours, dry it in vacuum and seal it up.

[0023] The fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com