Method for extracting and purifying natural phytosterol from oil deodorization distillate residual oil and technique thereof

A technology for deodorizing distillate and oil, applied in chemical instruments and methods, preparation of steroids, organic chemistry, etc., to achieve considerable economic value, protect the environment, and reduce the discharge of waste residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

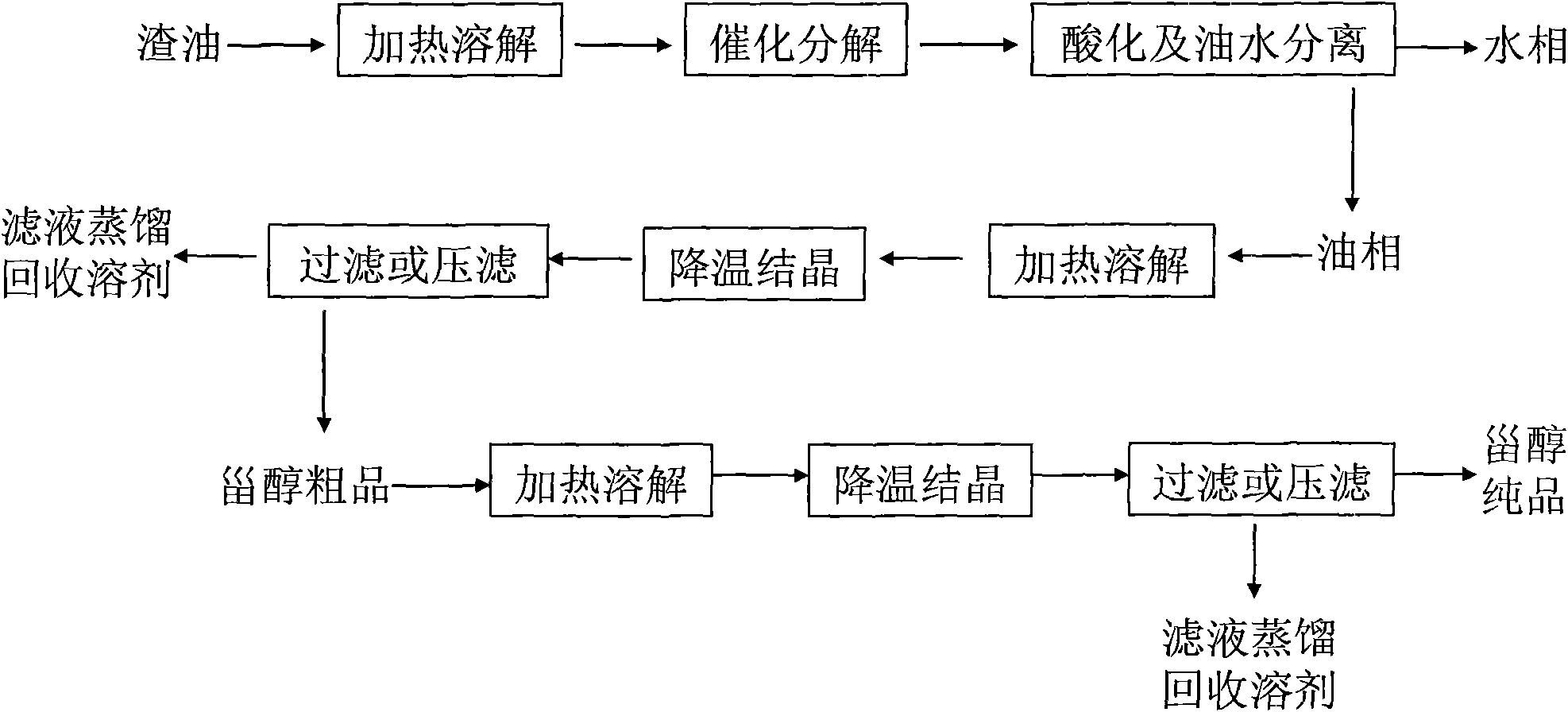

Method used

Image

Examples

Embodiment 1

[0028] Add 1Kg soybean deodorized distillate residue and 1000mL water into the reactor, heat to 100°C, stir for 60 minutes to mix the two evenly, then add 0.4Kg calcium oxide to the reactor, react at 100°C for 3 hours, add The hydrochloric acid was neutralized to pH=6, and the lower aqueous layer was separated and removed. Transfer the oil phase to a cold analysis kettle, then add 1000mL ethanol to the oil phase, heat to 70°C, stir until the oil phase is completely dissolved, then lower the temperature at a rate of 10°C / hour, and keep the stirring speed at 1.5 rpm during the cooling process When a large number of tiny grains are formed, heat and stir for 2 hours, and then continue to cool down at 4°C / hour. When the temperature reaches 15°C, stop stirring, keep the temperature at 15°C, and mature for 6 hours. Subsequently, the crystallization solution was transferred to a plate and frame filter press for pressure filtration, and the filter cake was washed with 1000 mL of ethano...

Embodiment 2

[0030] Add 1Kg of rapeseed oil deodorized distillate residue and 500mL of ethanol into the reactor, heat to 70°C, stir for 30 minutes to mix the two evenly, then add 3Kg of sodium hydroxide to the reactor, and react at 80°C for 2 hours , add sulfuric acid to neutralize to pH = 1, separate and remove the lower aqueous layer. Transfer the oil phase to a cold analysis kettle, then add 1000mL of petroleum ether to the oil phase, heat to 60°C, stir until the oil phase is completely dissolved, then lower the temperature at a rate of 8°C / hour, and keep the stirring speed at 1.5 rpm during the cooling process / min, when a large number of tiny crystal grains are formed, heat and stir for 1 hour, then continue to cool down at 2°C / hour, stop stirring when the temperature reaches 5°C, keep the temperature at 5°C, and mature for 12 hours. Then the crystallization solution was transferred to a plate and frame filter press for pressure filtration, and the filter cake was washed with 1000 mL ...

Embodiment 3

[0032]Add 1Kg of soybean oil deodorized distillate residue and 750mL of n-propanol into the reactor, heat to 90°C, stir for 30 minutes to mix the two evenly, then add 0.3Kg of potassium hydroxide to the reactor, and react at 97°C After 5 hours, sulfuric acid was added to neutralize to pH=5, and the lower aqueous layer was separated and removed. Transfer the oil phase to a cold analysis kettle, then add 2500mL of organic solvents listed in Table 1 to the oil phase, heat to 60°C, stir until the oil phase is completely dissolved, then cool down at a rate of 5°C / hour, and keep The stirring speed is 1.5 rpm. When a large number of tiny grains are formed, keep stirring for 1 hour, and then continue to cool down at 1°C / hour. When the temperature reaches 5°C, stop stirring, keep the temperature at 5°C, and mature for 24 hours. Subsequently, the crystallization solution was transferred to a plate and frame filter press for pressure filtration, and the filter cake was washed three times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com