Method for preparing conducting polymer modified active carbon

A conductive polymer and activated carbon technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of complex preparation of mesoporous carbon, difficulty in mass production, poor stability, etc., achieve abundant yield, improve adsorption performance, and improve the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Example 1: Adsorption of methyl orange by activated carbon / polyaniline composite

[0031] Weigh 5g of mesoporous activated carbon, add 100ml of 1mol / l hydrochloric acid solution, and carry out ultrasonic vibration for half an hour. Then add 1 g of aniline and continue shaking for half an hour. Prepare 2mol / l ammonium persulfate solution. Slowly add ammonium persulfate solution with a molar ratio of 1:1 to aniline using a dropping funnel. After the addition, continue to react in ultrasonic vibration for 2 hours. The resulting product is washed and dried.

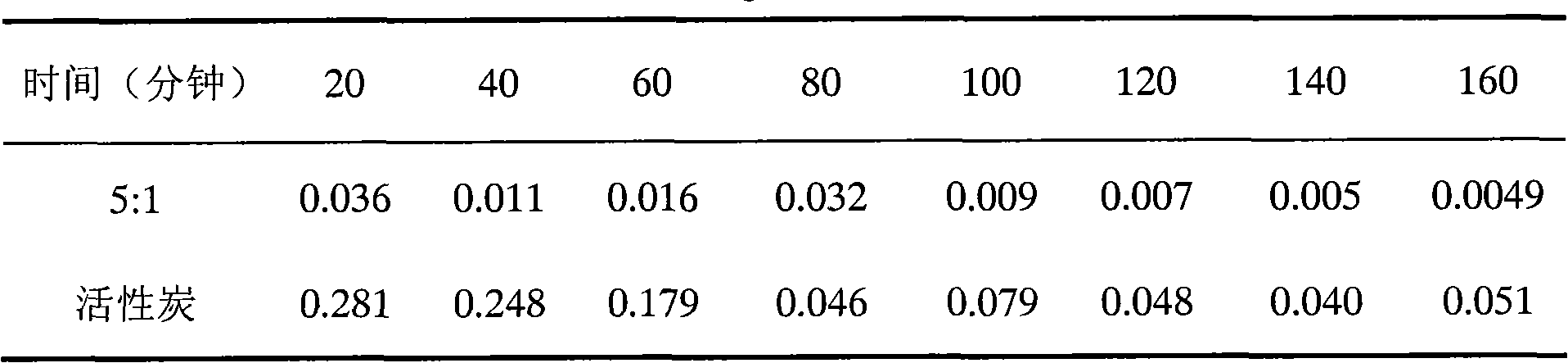

[0032] Take by weighing 0.5g gained product, add it in the 12mg / l methyl orange solution of 50ml, under the stirring effect of magnetic stirrer, take a sample every 20 minutes, measure the methyl orange in the solution on 721 spectrophotometer The absorbance of the absorbance represents the content of methyl orange in the solution, and the concentration of methyl orange in the solution is calculated. A total of 8 ...

example 2

[0036] Example 2: Adsorption of Malachite Green by Activated Carbon / Polyaniline Composite

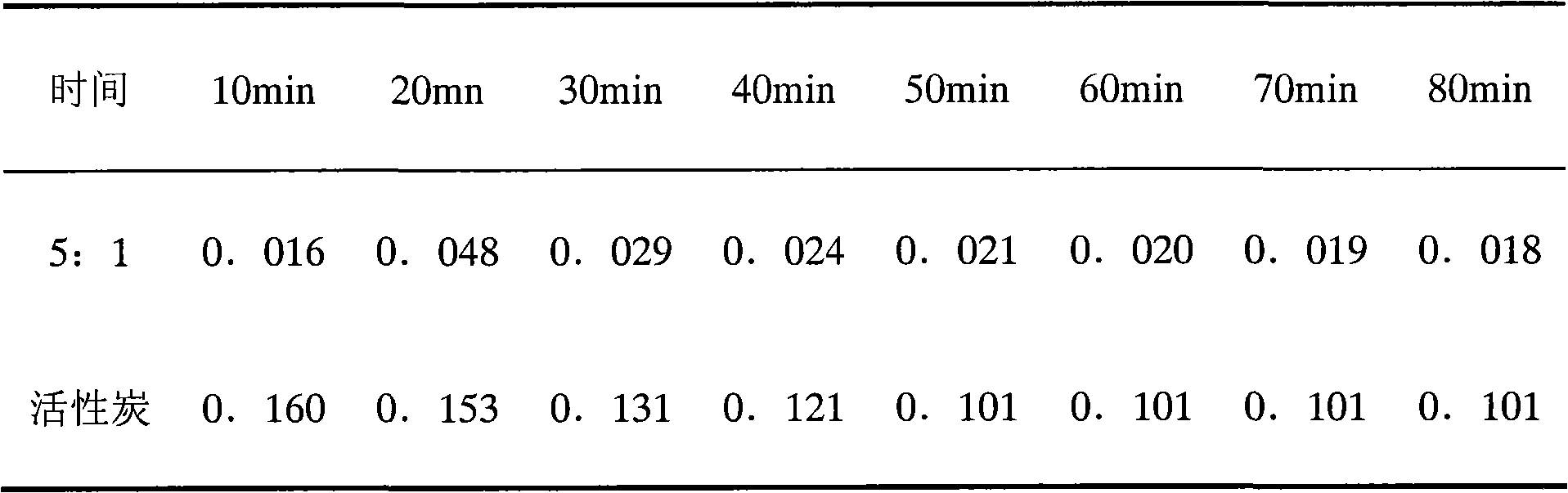

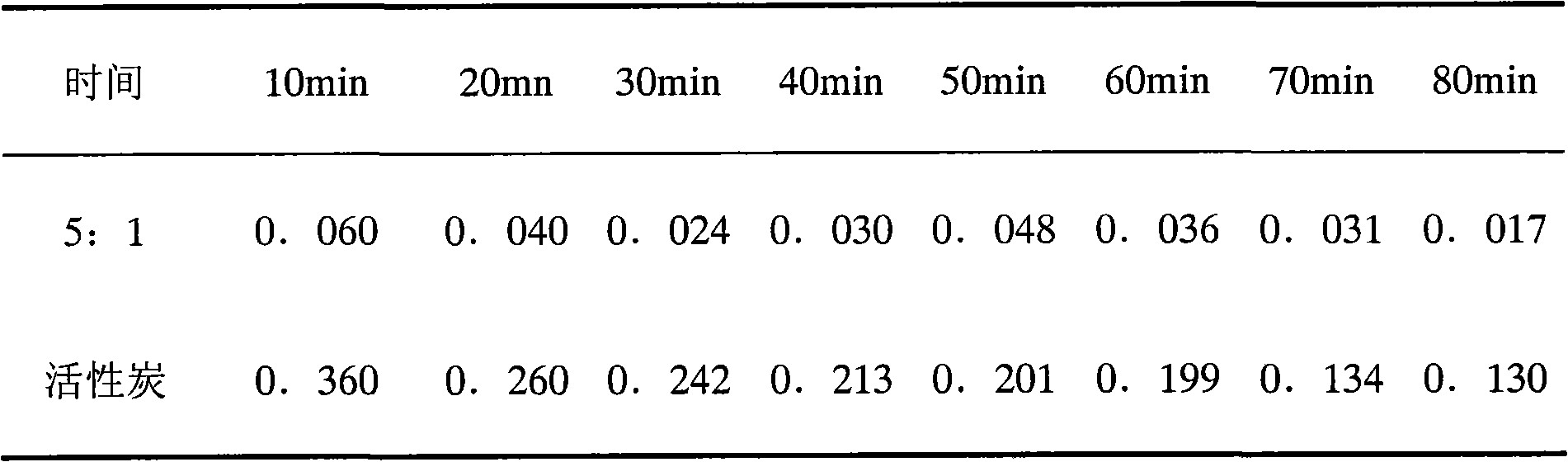

[0037] The high toxicity of malachite green makes it difficult to be degraded by microorganisms in wastewater treatment. Malachite green is a kind of green crystal with metallic luster. It belongs to triphenylmethane dyes and is a kind of synthetic triarylmethane industrial dyes. Chemical stains. The invention compares the adsorption properties of malachite green by polyaniline modified activated carbons with different mass ratios, so as to obtain the treatment performance of the modified activated carbons on industrial dye sewage.

[0038] Implementation Measures:

[0039] Weigh 100ml of 1mol / l hydrochloric acid solution. Weigh 5g of mesoporous activated carbon, add the weighed hydrochloric acid solution, and carry out ultrasonic vibration for half an hour. Then add 1 g of aniline and continue shaking for half an hour. Prepare 2mol / l ammonium persulfate solution. Slowly add ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com