Preparation method of polyimide nanofiber membrane containing porphyrin and application

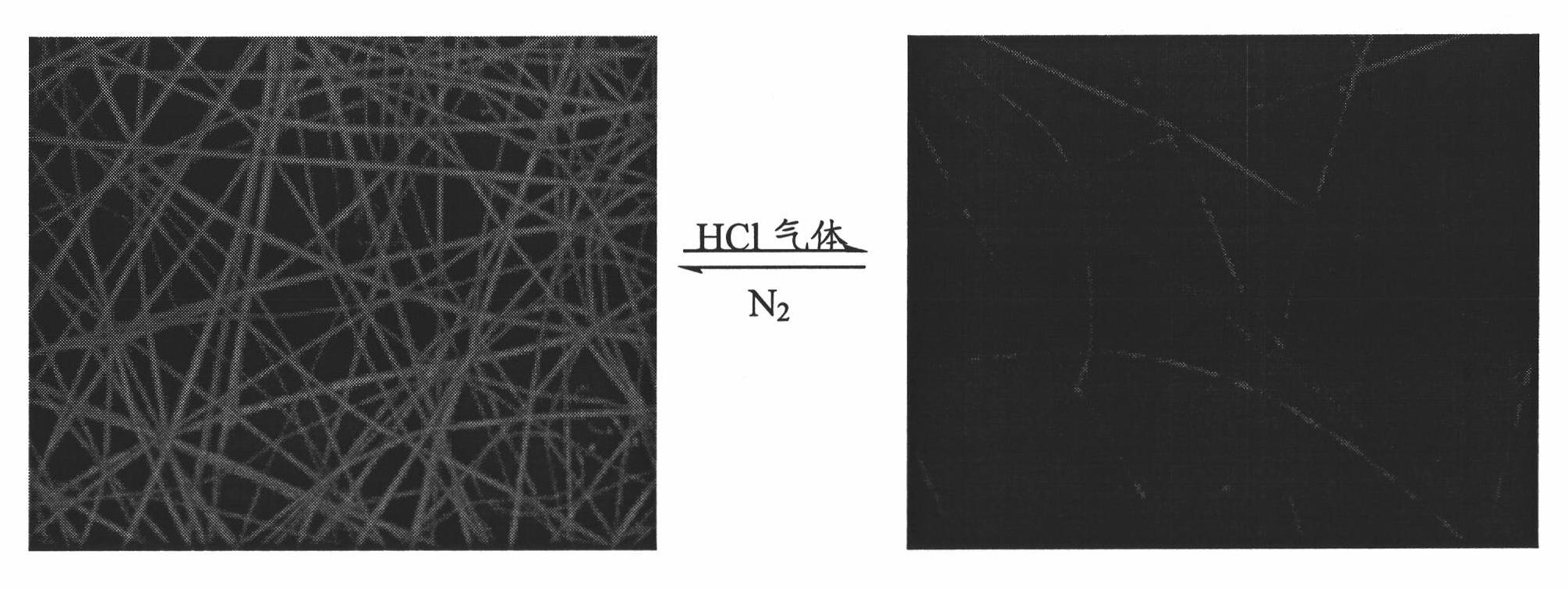

A nanofiber membrane, polyimide technology, applied in fiber processing, filament/thread forming, textile and papermaking, etc., to achieve the effect of easy sampling and intuitive detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Synthesis of porphyrin-containing polyamic acid

[0053] Under the protection of nitrogen, 5,15-diaminotetraphenylporphyrin (trans-DATPP) and 4,4'-diaminodiphenyl ether (ODA) with a molar ratio of 0.05:1 were used as diamine monomers in an ice-water bath , dissolved in N,N-dimethylacetamide (DMAc), and electromagnetically stirred to dissolve it to obtain a reaction system; then pyromellitic dianhydride (PMDA ) monomer was added to the reaction system twice, with an interval of half an hour between the two additions. After continuing to react in an ice-water bath for 4 hours, the reaction was continued for 16 hours at room temperature, and the reactant was poured into anhydrous methanol to obtain a reddish-brown Precipitation: The reddish-brown precipitate was repeatedly washed with methanol by suction filtration, and then dried in a vacuum oven at 60° C. to obtain a porphyrin-containing polyamic acid.

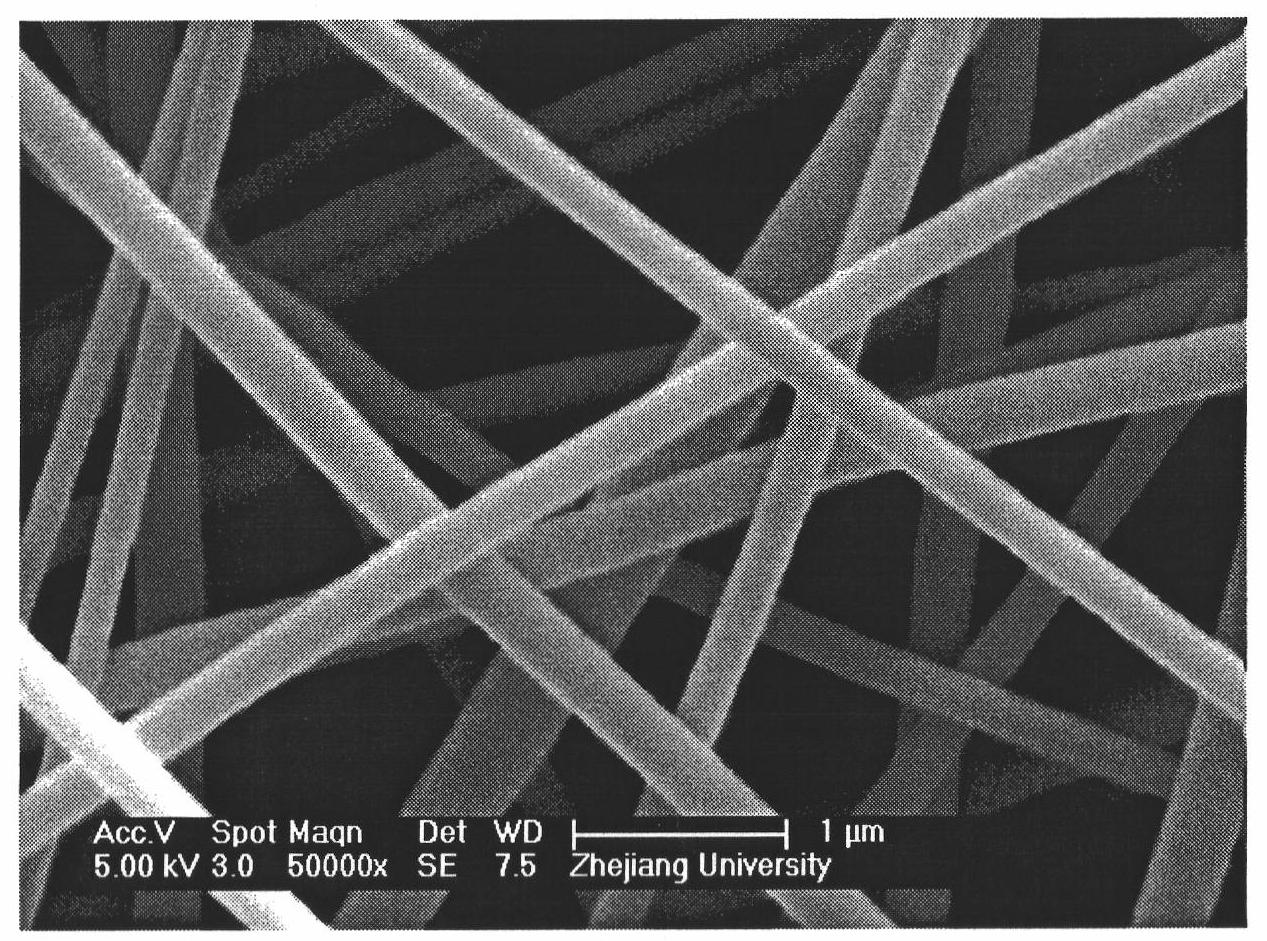

[0054] (2) Preparation of polyamic acid nanofiber membrane con...

Embodiment 2

[0062] (1) Synthesis of porphyrin-containing polyamic acid

[0063] Under nitrogen protection, in an ice-water bath, 5,15-diaminotetraphenylporphyrin (trans-DATPP) and all-para-triphenylenediamine (BAPB) with a molar ratio of 0.1:1 were used as diamine monomers, Dissolved in N,N-dimethylacetamide (DMAc), electromagnetically stirred to dissolve it to obtain a reaction system; then add pyromellitic dianhydride (PMDA) The monomer was added to the reaction system twice, with an interval of half an hour between the two additions. After continuing to react in an ice-water bath for 5 hours, the reaction was continued for 16 hours at room temperature, and the reactant was poured into anhydrous methanol to obtain a reddish-brown precipitate. ; The reddish-brown precipitate was repeatedly washed by suction filtration with methanol, and then dried in a vacuum oven at 60°C to obtain polyamic acid containing porphyrin.

[0064] (2) Preparation of polyamic acid nanofiber membrane containin...

Embodiment 3

[0072] (1) Synthesis of porphyrin-containing polyamic acid

[0073] Under nitrogen protection, 5,15-diaminotetraphenylporphyrin (trans-DATPP) and 4,4'-diaminodiphenyl ether (ODA) with a molar ratio of 0.15:1 were used as diamine monomers in an ice-water bath , dissolved in N, N-dimethylacetamide (DMAc), electromagnetically stirred to dissolve it to obtain a reaction system; then the 3, 3', 4, 4 '-Benzophenone tetra-acid dianhydride (BTDA) monomer was added to the reaction system twice, and the interval between the two additions was half an hour. After continuing to react in the ice-water bath for 6 hours, the reaction continued for 18 hours at room temperature. The reactant was poured into anhydrous methanol to obtain a reddish-brown precipitate, which was repeatedly suction-filtered and washed with methanol, and dried in a vacuum oven at 60°C to obtain a porphyrin-containing polyamic acid.

[0074] (2) Preparation of polyamic acid nanofiber membrane containing porphyrin

[...

PUM

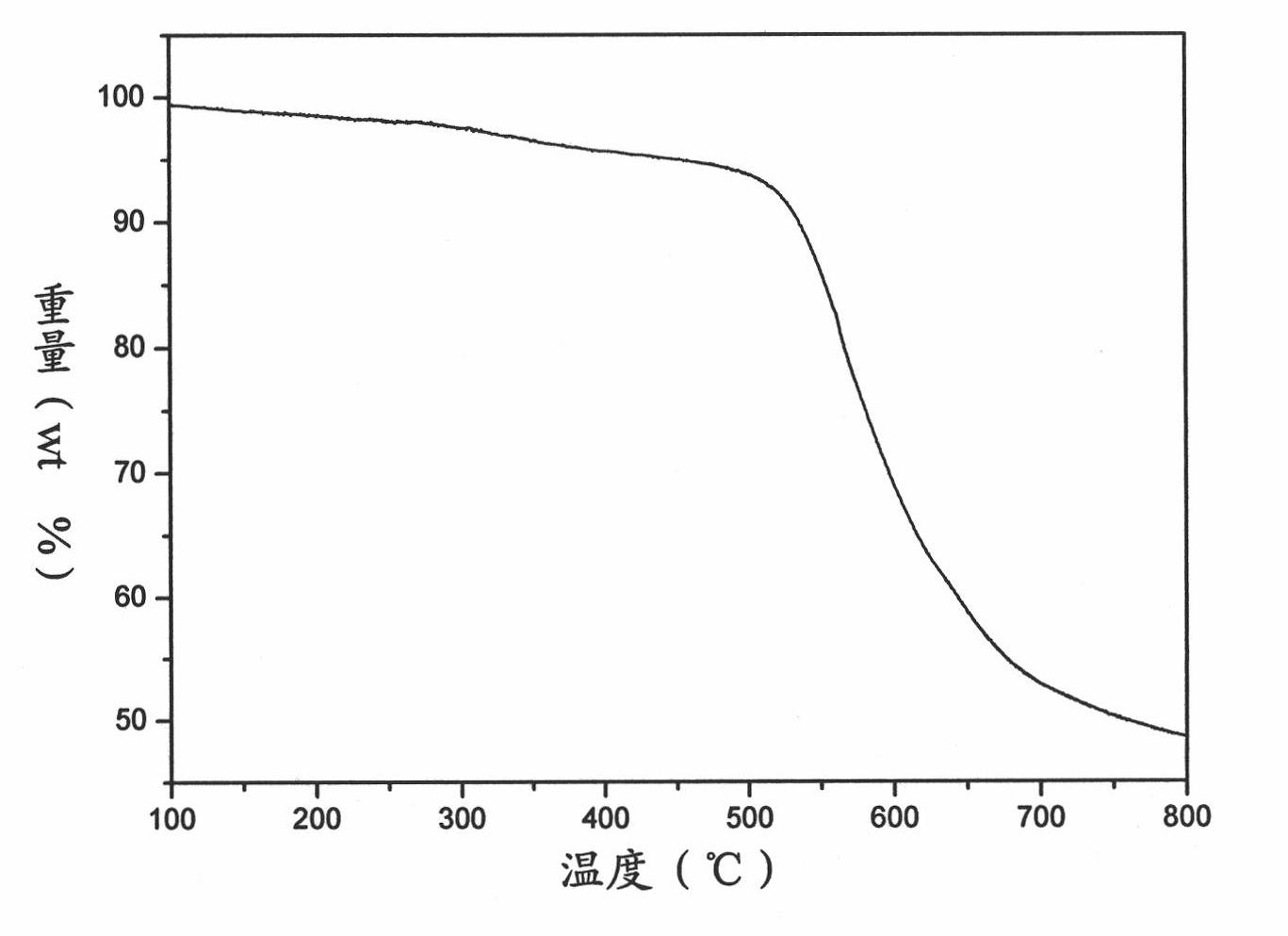

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com